Commercial kitchen sinks represent one of the most critical and customizable components in professional food service operations. Based on extensive industry research and practical applications across various commercial kitchen environments, this comprehensive analysis examines the full spectrum of customization options available to operators seeking optimal functionality, efficiency, and regulatory compliance.

Executive Summary

Commercial kitchen sink customization encompasses five primary categories: compartment configuration, drainboard systems, material selection, installation methods, and special design features. Each category offers multiple options tailored to specific operational requirements, space constraints, and budget considerations. The most common configuration remains the three-compartment sink with dual drainboards, constructed from 304 stainless steel and installed with floor-mounted legs for heavy-duty applications.

Compartment Configuration Options

Single Compartment Systems

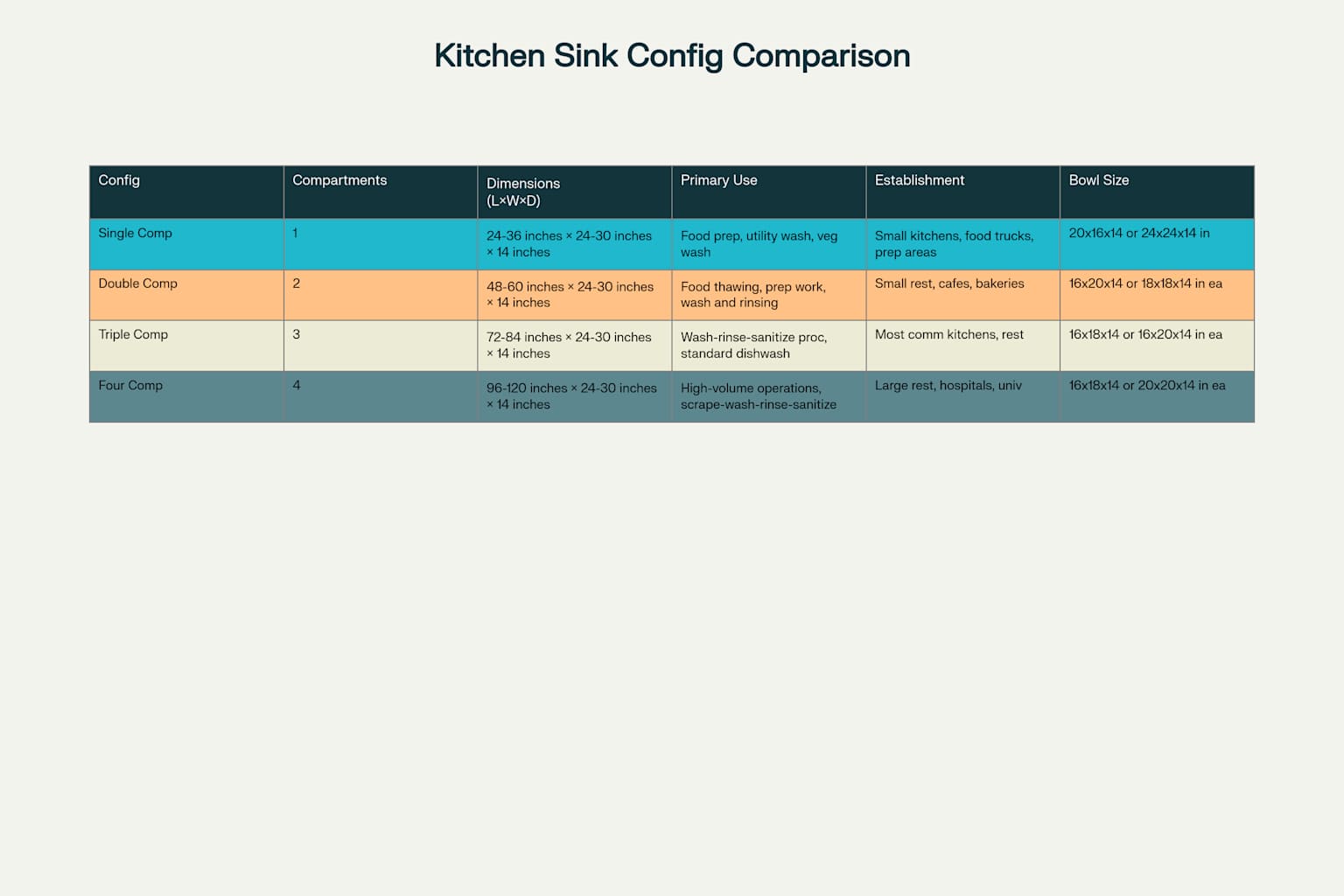

Single compartment sinks serve specialized functions in commercial kitchens, primarily food preparation and utility washing. These units typically measure 24-36 inches in length with bowl dimensions of 20x16x14 inches or 24x24x14 inches. Food trucks and small cafes frequently utilize single compartment configurations due to space limitations and focused operational needs.

Commercial Kitchen Sink Compartment Configurations: A comprehensive comparison of single, double, triple, and four-compartment sink systems showing dimensions, uses, and suitable establishments

Double Compartment Applications

Double compartment sinks provide enhanced functionality for food preparation and light washing operations. With overall lengths ranging from 48-60 inches, these systems accommodate two bowls measuring 16x20x14 or 18x18x14 inches each. Small restaurants and bakeries find double compartment systems optimal for thawing procedures and prep work segregation.

Triple Compartment Standards

The three-compartment sink represents the industry standard for manual warewashing operations, facilitating the required wash-rinse-sanitize process mandated by health codes. These systems typically span 72-84 inches in length with individual bowl dimensions of 16x18x14 or 16x20x14 inches. Most commercial kitchens implement triple compartment configurations to ensure regulatory compliance and operational efficiency.

Stainless steel three-compartment commercial kitchen sink with wall-mounted faucet and sturdy frame, ideal for efficient washing, rinsing, and sanitizing in professional kitchens

Four Compartment High-Volume Operations

Four compartment systems cater to high-volume operations requiring extended dishwashing capabilities. Measuring 96-120 inches in length, these units accommodate bowls ranging from 16x18x14 to 20x20x14 inches each. Hospitals, universities, and large-scale food service operations typically specify four compartment configurations to handle substantial dishware volumes and implement comprehensive scrape-wash-rinse-sanitize procedures.

Drainboard Configuration Systems

Standard Drainboard Options

Drainboard configurations significantly impact operational efficiency and space utilization. Standard restaurants typically implement single drainboards positioned left or right of the main compartments, providing efficient drying space for cleaned items. High-volume operations often specify dual drainboards to maximize drying capacity and streamline workflow processes.

Stainless steel commercial kitchen sink with single compartment and drainboard highlighting material quality and ease of cleaning

Space-Optimized Solutions

Compact installations frequently eliminate drainboards entirely to maximize available space in limited kitchen environments. This configuration suits operations with alternative drying methods or space-constrained layouts where every square foot requires optimization.

Commercial stainless steel single compartment kitchen sink with left-side drainboard and faucet, illustrating a common customization option for commercial kitchens

Material Selection and Specifications

Stainless Steel Grade Analysis

Material selection directly impacts durability, maintenance requirements, and operational costs. The three primary stainless steel grades offer distinct advantages for specific applications.

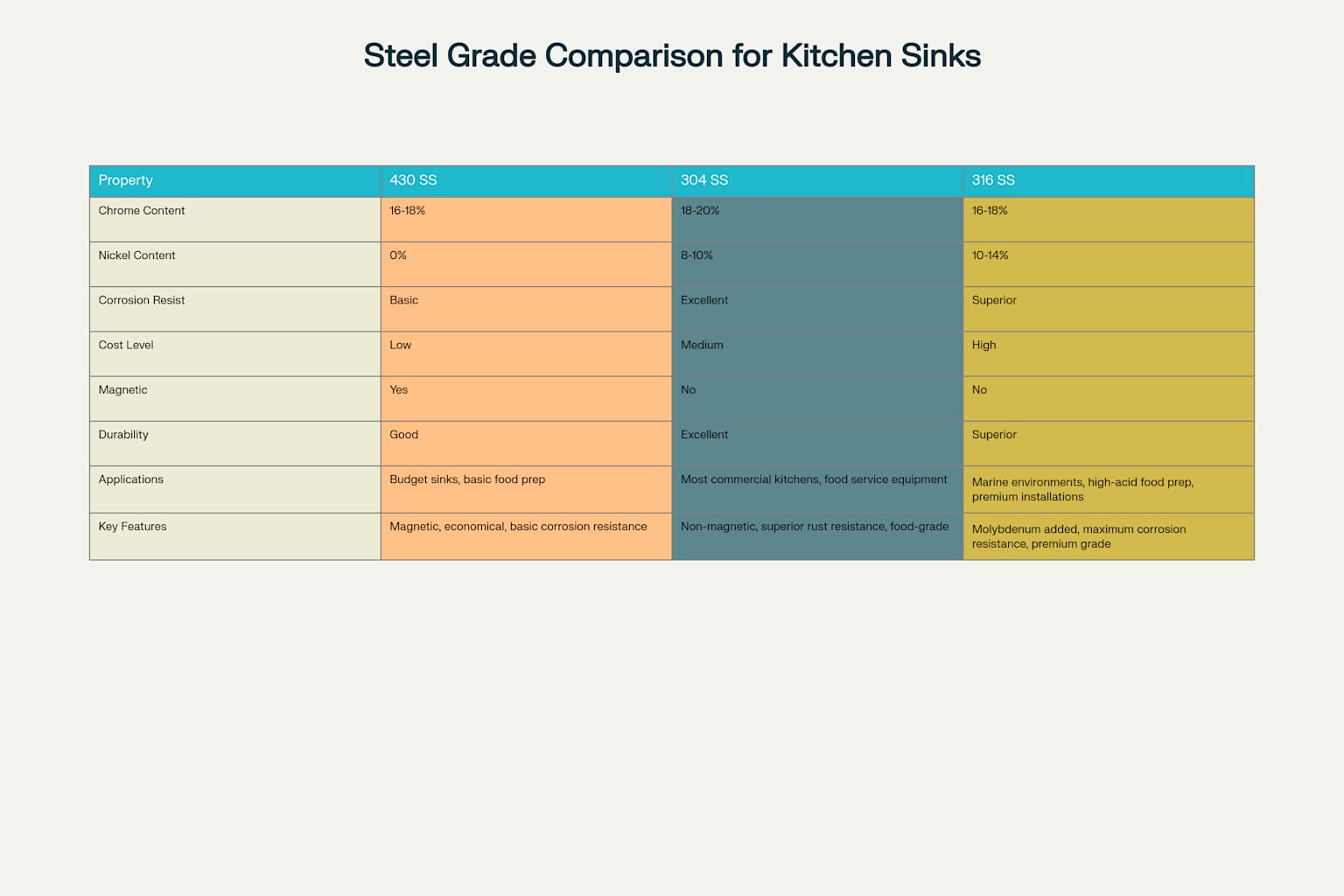

Stainless Steel Grades for Commercial Kitchen Sinks: Comparison of 430, 304, and 316 grades showing composition, properties, and applications

430 Stainless Steel Applications

Type 430 stainless steel contains 16-18% chromium without nickel content, making it magnetic and economical for budget-conscious operations. This grade provides basic corrosion resistance suitable for light-duty applications but may show wear in high-acid environments.

304 Stainless Steel Standard

Type 304 stainless steel, containing 18-20% chromium and 8-10% nickel, represents the industry standard for commercial kitchen applications. This non-magnetic grade offers excellent corrosion resistance, superior rust protection, and food-grade safety certification. Most professional kitchens specify 304 stainless steel for optimal durability and hygiene maintenance.

316 Stainless Steel Premium Grade

Type 316 stainless steel incorporates molybdenum additives alongside 16-18% chromium and 10-14% nickel content, providing superior corrosion resistance for demanding environments. Marine applications and high-acid food preparation areas benefit from 316 grade specifications, though the higher cost limits widespread adoption.

Gauge Specifications

Commercial sinks typically utilize 14, 16, or 18 gauge stainless steel construction. Lower gauge numbers indicate thicker material: 14 gauge measures 0.075 inches thick, 16 gauge measures 0.060 inches, and 18 gauge measures 0.048 inches. Heavy-duty applications require 14 or 16 gauge construction for enhanced durability and reduced noise transmission.

Installation Methods and Mounting Options

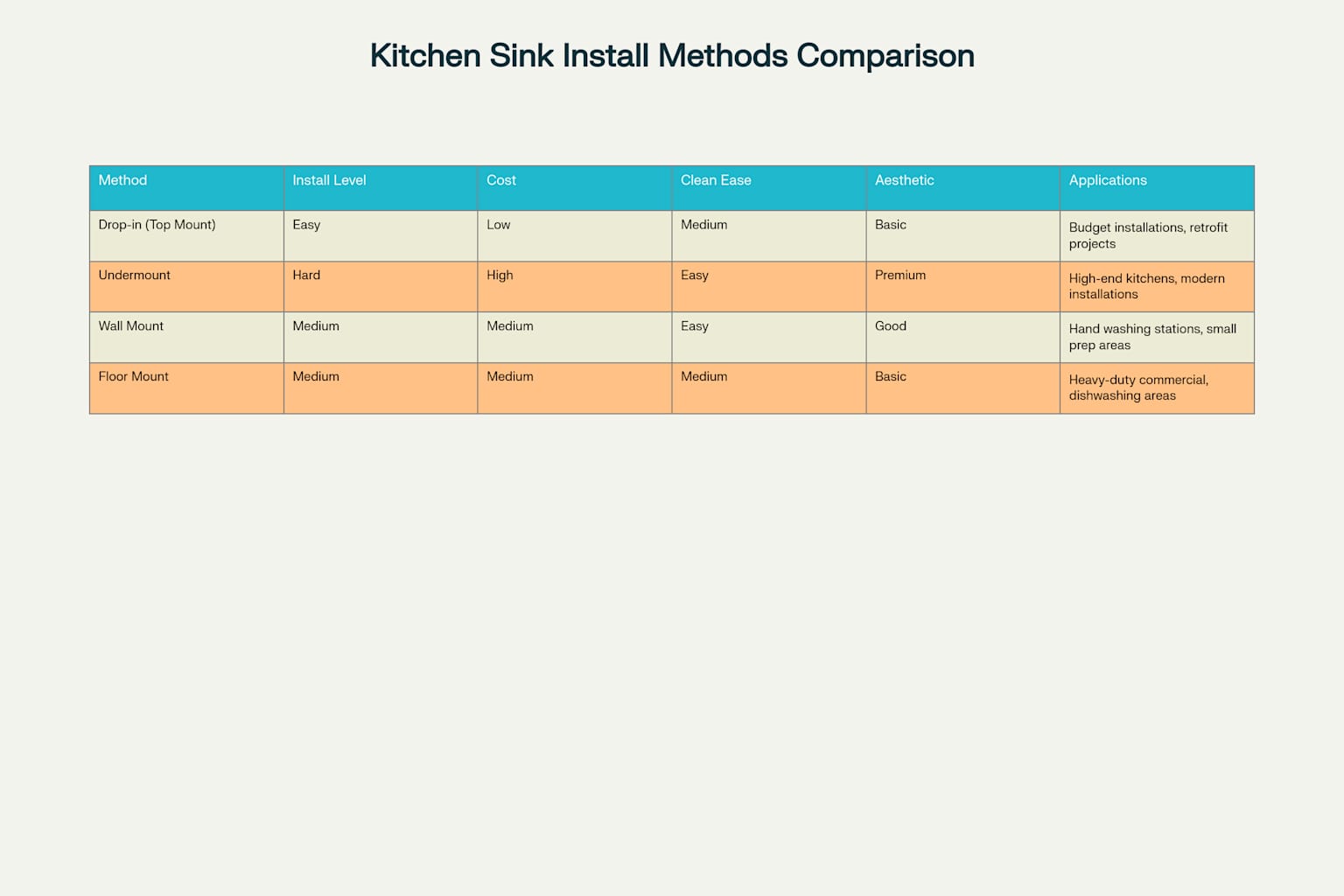

Commercial Kitchen Sink Installation Methods: Comparison of different mounting options and their characteristics for commercial applications

Drop-in Installation Systems

Drop-in or top-mount installation represents the most economical and versatile mounting method. The sink rim rests directly on the countertop, supporting the unit’s weight while providing compatibility with all countertop materials. This method simplifies installation and replacement procedures, making it ideal for retrofit projects and budget-conscious operations.

Undermount Premium Applications

Undermount installation creates seamless countertop-to-sink transitions, facilitating enhanced cleaning efficiency and premium aesthetics. This method requires solid countertop materials and professional installation expertise, resulting in higher initial costs but superior long-term functionality.

Wall-Mount Space Solutions

Wall-mounted installations optimize floor space utilization while facilitating thorough cleaning underneath the fixture. Hand washing sinks frequently employ wall mounting to comply with accessibility requirements and maintain hygienic conditions around food preparation areas.

Wall-mounted stainless steel hand washing sink with detailed dimensions for commercial kitchen use

Floor-Mount Heavy-Duty Systems

Floor-mounted sinks with adjustable legs provide maximum stability for large, heavy-duty applications. This installation method accommodates substantial weight loads while offering height adjustability to ensure proper ergonomics and plumbing connections.

Three-compartment stainless steel commercial kitchen sink with utensil rack illustrating user customization options

Special Design Features and Applications

Corner Unit Space Optimization

Corner sink configurations maximize space utilization in compact kitchen layouts while maintaining full functionality. These specialized units typically feature angled bowl arrangements or L-shaped designs that fit efficiently into corner installations.

Modern kitchen corner sink installation optimizing space with a sleek stainless steel sink and faucet

Stainless steel three-compartment corner commercial kitchen sink with dual drainboards for space-saving and efficient workflow

Hand Washing Compliance Systems

Dedicated hand washing sinks ensure regulatory compliance and prevent cross-contamination in food service operations. These units typically measure 10x14x5 inches with wall-mounted installation and hands-free operation capabilities. Health codes mandate separate hand sinks within 20 feet of food preparation areas.

Mop Sink Utility Applications

Mop sinks serve janitorial functions with deeper basins and floor-level installation for easy bucket filling and emptying. These units typically feature 16 gauge stainless steel construction with coved corners and integrated overflow systems.

Custom Fabrication Solutions

Custom fabrication addresses unique operational requirements through engineered solutions. Specialized applications may require non-standard dimensions, integrated accessories, or modified configurations to optimize specific workflow patterns.

Custom stainless steel commercial kitchen sink with multiple compartments and integrated cleaning features

Size and Layout Customization

Standard Dimensional Specifications

Commercial sink manufacturers offer standardized sizing to accommodate common kitchen layouts and equipment spacing requirements. Standard prep sinks measure 4-6 feet in length with 24 or 36-inch widths, while compartment sinks range from 48 inches for double units to 120 inches for four-compartment systems.

Custom Sizing Solutions

Custom sizing ensures optimal integration with existing kitchen layouts and equipment configurations. Operators frequently specify non-standard dimensions to maximize available space or accommodate specific operational workflows.

Ergonomic Considerations

Proper sink height and depth specifications enhance operator comfort and efficiency while reducing workplace injuries. Standard commercial sinks install at 36-inch deck height with 12-14 inch bowl depths, though custom applications may require alternative specifications.

Industry Applications and Use Cases

Small-Scale Operations

Food trucks and small cafes typically implement single or double compartment configurations with compact footprints and basic stainless steel construction. Budget constraints often drive material selection toward 430 grade stainless steel with drop-in installation methods.

Standard Restaurant Applications

Traditional restaurants specify three-compartment systems with single drainboards and 304 stainless steel construction. Floor-mounted installation with adjustable legs accommodates varying equipment heights and plumbing configurations.

High-Volume Institutional Settings

Hospitals, universities, and large-scale food service operations require four-compartment systems with dual drainboards and premium 316 stainless steel construction. These applications prioritize durability and regulatory compliance over initial cost considerations.

Specialized Industry Requirements

Seafood processing and marine applications benefit from 316 stainless steel specifications due to enhanced salt water and acid resistance. These environments typically specify custom fabrication to address unique operational requirements and harsh operating conditions.

Regulatory and Compliance Considerations

Health Code Requirements

Local health departments mandate specific sink configurations, quantities, and installation methods for commercial food service operations. Three-compartment sinks with proper sizing represent minimum requirements for manual warewashing procedures, while separate hand sinks ensure hygiene compliance.

NSF Certification Standards

NSF International certification ensures equipment meets rigorous sanitation and safety standards for commercial food service applications. Certified sinks demonstrate compliance with materials safety, design standards, and performance requirements essential for regulatory approval.

ADA Compliance Specifications

Americans with Disabilities Act requirements influence sink height, clearance, and accessibility features in commercial installations. Wall-mounted hand sinks and specific dimensional requirements ensure universal accessibility in food service environments.

Conclusion

Commercial kitchen sink customization offers extensive options to optimize functionality, efficiency, and regulatory compliance across diverse food service applications. Success depends on careful evaluation of operational requirements, space constraints, budget considerations, and regulatory mandates. The three-compartment sink with dual drainboards, constructed from 304 stainless steel and installed with floor-mounted legs, remains the most versatile solution for standard commercial kitchen applications.

Future trends indicate increased demand for custom fabrication solutions, premium material specifications, and integrated technology features. Operators must balance initial investment costs against long-term operational efficiency and maintenance requirements when selecting optimal sink configurations for their specific applications.

Understanding these customization options enables informed decision-making that enhances operational efficiency while ensuring regulatory compliance and long-term durability in demanding commercial kitchen environments.