Whether you’re running a small café or a bustling restaurant, finding the right commercial dishwasher can make all the difference in your daily operations. This comprehensive guide will walk you through everything you need to know about choosing, installing, and maintaining commercial dishwashers, from understanding different types to getting the most out of your investment.

Types of Commercial Dishwashers

When you’re dealing with a busy kitchen, you’ll quickly realize that manual dishwashing just can’t keep up with the pace. That’s where commercial dishwashers come in – these are heavy-duty machines specifically designed for speed and handling large volumes of dishes. Understanding the different types available will help you make the best choice for your specific needs.

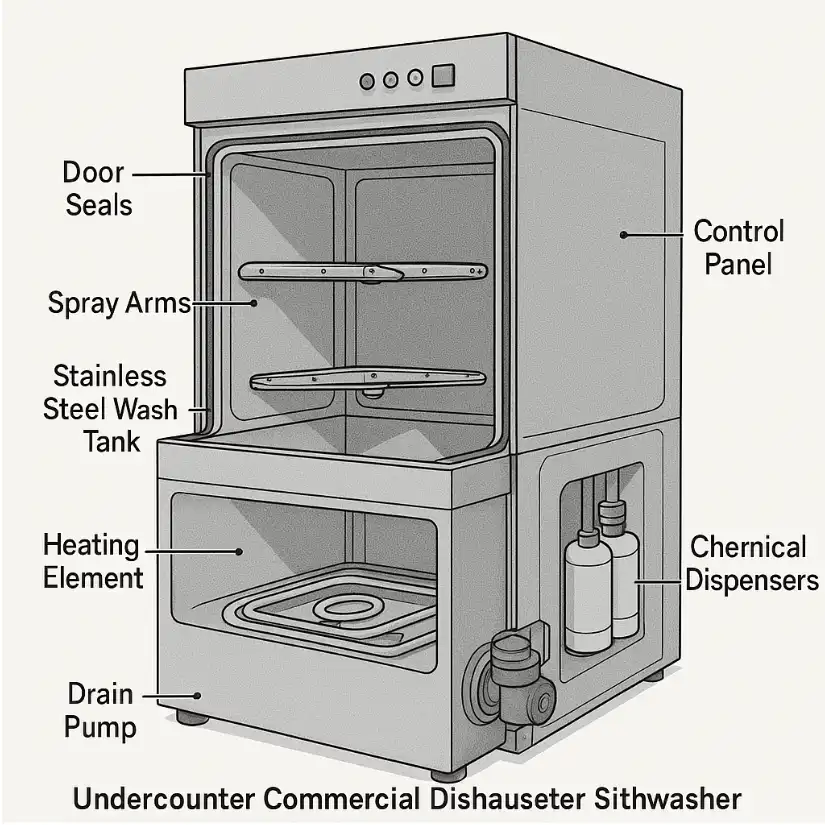

First, let’s talk about undercounter dishwashers, which are perfect for smaller operations. These compact units fit neatly under a table, making them ideal for small cafés or bars where space is at a premium. Moving up in size, you’ll find door-type (also called hood) machines, which are front-loading units that you lift by a hood. These offer good mid-size capacity and are popular in many restaurants.

For higher-volume operations, conveyor dishwashers are the way to go. These systems use a continuous belt or racks to move dishes through the washing process, making them perfect for busy kitchens. At the top end, flight dishwashers feature large multi-section conveyors designed for the busiest operations that need to handle massive volumes of dishes.

When it comes to how these machines work, you’ll encounter two main categories. High-temp machines heat water to around 180°F and often require a separate booster heater to meet proper sanitation temperatures. On the other hand, low-temp machines use cooler water combined with chemical sanitizers – for example, systems that work with Auto-Chlor chemical dispensers.

The capacity differences between these machines are quite significant. Undercounter machines typically handle 20-40 racks per hour, which works well for smaller operations. However, conveyor or flight machines can wash hundreds of racks per hour, making them essential for high-volume restaurants. Popular manufacturers like Hobart, Meiko, Winterhalter, CMA, and Jackson make models in each style, and you’ll even find some undercounter models that come in ADA-compliant heights – these are shorter units designed to fit under lower countertops for better accessibility.

Interestingly, undercounter machines are particularly common at bars for washing glassware. In fact, what’s often called a bar dishwasher or glasswasher is typically just a small undercounter unit equipped with extra rinse jets specifically designed for delicate glassware. Meanwhile, conveyor machines might include built-in drying sections or high-speed fans to dry glassware as it exits the washing cycle.

The key to success is choosing a machine that’s properly rated for your peak demand. For instance, a 30 rack-per-hour undercounter unit can handle a few hundred pieces per service, which works well for smaller establishments. However, if you’re running a large restaurant that serves over 1000 covers per shift, you’ll need a conveyor system rated for 200+ racks per hour to keep up with demand.

Dishwashing Station Setup (Sink, Plumbing & Safety)

Creating an efficient dishwashing station goes far beyond just placing a machine in your kitchen. The layout of your dishroom is absolutely crucial for smooth operations and food safety. Almost every setup includes a pre-rinse sink or faucet positioned right next to the dishwasher, which allows staff to quickly knock off food scraps before washing.

The workflow should be logical and efficient. Typically, plates move from the soiled sink into the machine, then onto a clean dish table or bench for drying and stacking. Many successful kitchens use a two-table system: a soiled table (often equipped with a small sink basin) on the loading side, and a clean table on the unloading side. These benches and tables aren’t just nice-to-have accessories – they’re essential components that provide the workspace needed to scrub and sort dishes before and after washing.

When it comes to plumbing, there are critical safety requirements you can’t ignore. Commercial dishwashers must have either an air gap or backflow preventer on the drain to protect the water supply from contamination. Most building codes require either a physical air gap (which creates a visible break in the drain path) or a certified backflow device. In high-risk applications, some regions even require a separate break tank – essentially a small water reservoir between the mains and the machine – under what’s called “Category 5” rules.

On the supply side, proper setup means ensuring the incoming water has both a shutoff valve and strainer. Additionally, it’s crucial that the dishwasher drain connects to an indirect waste receptor or properly trapped floor drain, rather than draining back into sinks, which could create contamination issues.

Planning your electrical requirements in advance is equally important. Most commercial machines operate on 208-240V power, with typical undercounter units drawing 20-40 amps. Larger conveyor or flight machines may require 50+ amps on three-phase power. For example, a popular high-temp undercounter model might need a 40A circuit even though the machine itself is rated for 30A. Always verify the exact amperage requirements by consulting the spec sheet or working with a qualified installer, as the dishwasher will be clearly marked with its required circuit capacity and protective device size.

Don’t overlook water pressure issues either. Low water pressure can cause a dishwasher to malfunction or fail to fill properly, so some installations include a booster pump on the water line when the supply pressure is insufficient.

Finally, making sure your installation is both ergonomic and code-compliant will save you headaches down the road. Load height shouldn’t exceed about 17-18 inches for staff comfort, and if you’re installing at ADA-level countertops, make sure you’ve selected an ADA-compliant model. Many manufacturers offer ADA-compliant versions that are just a couple of inches shorter, making them perfect for dishrooms used by shorter staff members or those with disabilities.

Essential Accessories and Equipment

Every commercial dishwasher depends on a variety of accessories to function smoothly and efficiently. Understanding what you’ll need beyond the machine itself will help you create a complete, functional dishwashing operation.

Starting with the basics, dish tables and benches are absolutely essential. You’ll want separate tables for the soiled and clean sides – often 3-compartment or 2-compartment dish tables that provide designated areas for pre-scraping, loading, and unloading. Some of these tables come with built-in sinks or compartments specifically designed for soaking heavily soiled items.

Next, you’ll need the right racks and baskets to actually load your machine. Standard dish racks work well for plates, bowls, and utensils, while specialized glass racks feature compartmentalized trays that keep glassware secure during washing. You’ll also want cutlery baskets and silverware inserts to keep dishes organized throughout the process. For example, a compartment glass rack with 9 or 30 slots can hold stemware securely, preventing breakage during the wash cycle.

For larger operations, basket trolleys and dollies become invaluable. These heavy-duty wire trolleys on wheels can carry multiple loaded racks (often 7-tier racks measuring 50×50cm) from dish tables to the washer and back, significantly reducing the number of steps your staff needs to take. You’ll commonly find these in large kitchens where efficiency is paramount.

If you’re using low-temp washers, you’ll need reliable sanitizer and chemical dispensers. Companies like Auto-Chlor or Ecolab provide automatic dispensers along with monthly service to keep everything running smoothly. It’s important to maintain an ample supply of detergents, rinse aids, and sanitizers, as mixing ratios are critical for proper sanitation. Make it a daily routine to check temperatures and chemical levels using test strips to ensure you’re meeting sanitation standards.

For high-temperature dishwashers, a booster heater is often necessary. These machines must reach 180-195°F for the rinse cycle, so many facilities install a separate booster heater or instant-boil tank to bring the water entering the machine up to that temperature. This is especially important in colder climates and ensures your sanitizing rinse meets NSF standards.

Don’t forget about backflow prevention, which is often overlooked but absolutely mandatory. Most machines have a backflow device built into the water inlet, or you’ll need to install a pipeline air gap. This protects your potable water supply in case of pressure reversal and is required by plumbing codes. Check whether your model has an internal check valve or if you need to install a separate one – Type AA, AB, or AD air gaps are common solutions.

A pre-rinse spray valve and sink setup is another must-have component. You’ll need a powerful hand spray (pre-rinse gun) to remove food debris from plates before washing, and it should be wall-mounted near the sink or bench for easy access. The sink often serves double duty as a place to scrape and rinse dishes. Many kitchens also incorporate a triple-sink system for manual washing alongside the machine.

Finally, consider your drying and storage needs. Depending on local health codes, air-drying on racks may be required rather than towel drying. Some operators set up dish or utensil cabinet space near the clean bench to store sanitized items. While not exactly part of the dishwasher itself, your dishroom layout should include adequate space for drying racks or hanging glass racks as needed.

With the right tools readily available, your dishwasher will run much more efficiently. Always keep extra clean racks and baskets on hand, because when a rack is missing or broken, staff tend to improvise, which slows down the entire operation. Don’t forget practical accessories like dishwashing gloves and scrub brushes for staff working at the pre-rinse sink.

Power, Water, and Operational Considerations

Commercial dishwashers are serious pieces of equipment that require careful attention to power and water requirements. You’ll need a dedicated electrical circuit using copper wire rated for 90°C that exactly matches your machine’s specifications. For instance, a common undercounter high-temp unit might require 30.5 amps on 208-240V single-phase power, which means you’ll need a 40A breaker to handle the load safely. Larger door or conveyor machines can easily require 100A or more on three-phase power, so always follow the manufacturer’s wiring diagram and ensure proper grounding. Many commercial dishwashers ship without plugs and require permanent wiring by a qualified electrician.

Your water supply needs to provide steady pressure between 15-65 PSI. If your water pressure is higher than this range, you’ll need to install a pressure regulator to prevent damage to the machine. Cold water hookups often benefit from an integrated water softener on the line, as hard water can quickly damage dishwashers and reduce their lifespan. If your water pressure falls below about 25 PSI, consider installing a booster pump on the incoming water line to ensure the machine’s fill valve works properly.

During daily operation, your staff will need to follow a consistent routine to get the best results. First, they should pre-scrape dishes and run them through the pre-rinse or underflow rinse cycle briefly to remove food debris. Next, they’ll load racks with dishes spaced properly – overloading can block the spray jets and reduce cleaning effectiveness. After closing the hood or door (or activating the conveyor system), they’ll wait for the wash and rinse arms to complete their cycle while monitoring that indicator lights or timers are working correctly. Finally, they’ll unload racks onto the clean side tables and allow items to air-dry unless the machine has a built-in drying feature.

Proper sanitization is crucial and differs between machine types. High-temp machines automatically sanitize through heat, aiming for a 180°F final rinse temperature. Low-temp machines rely on chemicals, so operators must keep sanitizer dispensers filled and regularly check sanitizer levels. For example, these machines may use 100 ppm chlorine or a quaternary ammonium (quat) sanitizer, with only a few PPM needed in the final rinse. Staff should test pH and chlorine levels with test strips at the start of every shift – this should be a standard operating procedure for both safety and code compliance.

Most modern machines include built-in controls that alert operators to problems like low rinse temperature or insufficient chemical levels. When a machine displays an error or temperature alarm, troubleshooting typically involves checking whether the booster heater is functioning properly (for high-temp units) or verifying that chemical pumps and water flow are working correctly (for low-temp machines). Regular maintenance includes cleaning the strainer (trash catcher) and filter screens to prevent clogs that can affect performance.

Weekly maintenance should include a full deliming or descaling cycle. Many dishwashers have a rinse-only mode that can be used with an approved descaler to flush mineral deposits out of the tank. This keeps spray arms and sensors operating at peak efficiency.

As a practical tip, always rinse and stack clean dishes in a way that maintains their sanitary condition. Don’t let clean items touch soiled surfaces or the floor, and keep them covered when possible. In our experience, clearly labeling the clean versus dirty sides and training staff to follow the proper workflow prevents cross-contamination. Many leasing companies or service technicians offer staff training on proper use and maintenance, which can save both time and money by preventing avoidable breakdowns.

Buying, Brands, and Budget Considerations

Restaurant owners have several options when it comes to purchasing dishwashers, each with its own advantages and considerations. New units from manufacturers or dealers cost more upfront but come with warranties and the latest features. Used machines can be found through restaurant auctions, online marketplaces, or restaurant supply resellers – you’ll often see quality used Hobart or Meiko dishwashers available when restaurants close or upgrade their equipment. A good strategy is to inspect used machines in person, checking carefully for rust, leaks, or other signs of wear.

When it comes to where to shop, many operators start with restaurant equipment dealers or specialized websites. Some smaller undercounter models are even available through Amazon or big-box stores, though these are still commercial-grade in function. In major cities, you’ll find specialized suppliers – for example, Electrolux Professional and other commercial kitchen equipment companies have distributors in most regions. Online retailers like WebstaurantStore, KaTom, and industry classified sites offer both new and refurbished dishwashers with detailed specifications and customer reviews.

Several brands dominate the commercial dishwasher market, each with their own strengths. In North America, Hobart and Jackson are extremely common and well-regarded, but don’t overlook other quality manufacturers. European brands like Meiko and Winterhalter have built reputations for efficiency and innovative features. CMA/Insinger, based in Canada, is another major manufacturer worth considering. For budget-conscious operations, brands like Admiral Craft or Continental offer solid undercounter options without breaking the bank.

Interestingly, the brand “Adexa” that you might encounter is actually a UK brand that’s part of the Insinger/CMA product line, often found through UK and Australian suppliers. While Bosch primarily serves home kitchens, they do make 18″ and 24″ ADA-height dishwashers suitable for lighter commercial duty. When working with a dealer, ask about specific model lines – for instance, Hobart’s LXe and AM series, or Meiko’s FX and PT series – to understand the features and capabilities of different options.

Don’t forget to budget for essential accessories and replacement parts. You’ll need additional racks and baskets in the correct sizes, as broken racks should be replaced immediately to maintain efficiency. A proper dishwasher rack trolley becomes essential if your kitchen handles large volumes, as it makes moving empty and loaded racks much easier. For door and conveyor machines, replacement curtains and conveyor sprockets are wear items that you’ll need to replace periodically.

Proper detergents and sanitizers from reliable sources are crucial for keeping your machine calibrated and functioning correctly. Many dealers recommend service plans that include regular professional cleaning to clear scale buildup and check heating elements, even if you own the machine outright.

When it comes to budgeting, new undercounter machines typically range from a few thousand dollars for basic models up to $10,000 or more for large, advanced units. Conveyor systems start around $15,000 for entry-level models and can exceed $50,000 when fully equipped with all options. If budget is a concern, used or rebuilt dishwashers refurbished by specialized companies can significantly reduce costs while still providing reliable performance. Just make sure any used unit is appropriate for your volume requirements and includes the features you need, such as an integrated sanitizer cycle or booster heater.

Finally, consider the long-term operating costs beyond the initial purchase price. Modern machines often carry Energy Star ratings, which can help you compare efficiency. High-temp dishwashers typically use more hot water, while well-configured low-temp machines use less water and energy but have ongoing costs for sanitizer chemicals. Discuss these trade-offs with your sales representative, as some advanced flight-type dishwashers now feature heat recovery systems or self-cleaning capabilities that can justify their higher upfront cost in large operations.

Practical Tips and Maintenance

From hands-on experience in commercial kitchens, several practical strategies can make a significant difference in your dishwasher’s performance and longevity. Start by training at least two people on daily startup and shutdown procedures – this ensures you’re never stuck without someone who knows how to operate the machine properly. Each morning, check your dishwasher by running an empty cycle to verify that both heat and chemicals come up to proper specifications before the rush begins.

Maintaining cleanliness around the machine is crucial for both safety and equipment longevity. Keep the area clean and dry to prevent slips and potential damage to the machine. Water on the floor can also indicate a leak that needs immediate attention, so don’t ignore these warning signs.

Establishing a regular maintenance schedule will save you money and headaches in the long run. Your in-house staff should empty the filter basket at least daily, wipe down door seals and hood edges, and clear the strainer of any debris that could cause clogs. Weekly or biweekly, take time to inspect the spray nozzles, as these can become blocked with lime buildup or food particles. Monthly maintenance should include taking apart filter screens and washing them thoroughly, as well as testing the final rinse temperature to ensure it reaches 180°F for high-temp machines.

If you’re operating a low-temp machine, make it a daily habit to test sanitizer concentration using test strips, and check rinse cycle temperature weekly. These simple tests can prevent serious sanitation issues and potential health code violations.

When something breaks – whether it’s a heater element, pump, or other component – always call a qualified technician rather than attempting repairs yourself. A broken high-temp booster, for instance, means your machine can’t properly sanitize and must be fixed immediately. Keep your machine’s model and serial number easily accessible, along with its amperage specifications, so you can provide accurate information when troubleshooting with a technician. Documenting issues helps tremendously – for example, noting “Dishwasher LEDs flickering, drawing 34 amps” gives a technician valuable diagnostic information.

If you ever encounter the term “dishwasher BIM” in your research, this refers to Building Information Modeling files that architects and engineers use when designing commercial kitchens. Manufacturers often provide CAD or BIM models of their equipment, so if you’re planning a new build or renovation, sharing these files with your designer can help ensure proper space allocation and utility planning.

Conclusion

A commercial dishwasher truly serves as the backbone of any restaurant’s sanitation system, and making informed decisions about choosing, installing, and maintaining it properly will save you both time and money in the long run. By carefully selecting the right type of machine – whether it’s an undercounter unit for a small café, a hood-style machine for mid-volume operations, or a conveyor system for high-volume restaurants – you’re setting the foundation for efficient operations.

Equally important is equipping your dishwasher with the correct accessories, from proper tables and racks to booster heaters and chemical dispensers, all while following good operational practices like regular cleaning, sanitizer testing, and professional servicing. Whether you choose to buy new from a dealer, find a quality used machine at auction, or even source parts and smaller units online, always ensure your setup complies with local codes for backflow prevention and sanitation standards.

With the right setup and maintenance routine, even the busiest restaurant can handle large volumes of dishes efficiently, freeing up your staff to focus on what they do best – cooking great food and providing excellent service. Remember that an ounce of preventive maintenance keeps your dishwasher running smoothly, which in turn keeps your entire operation cleaner, safer, and more profitable.