After fifteen years of working in commercial kitchen design and equipment installation, I’ve seen firsthand how the right commercial dishwasher setup can transform a restaurant’s efficiency. From small cafes to large institutional kitchens, selecting and maintaining commercial dishwashing equipment requires understanding multiple components, energy requirements, and operational considerations that directly impact both costs and performance.

Understanding Commercial Dishwasher Types and Applications

High-Temperature vs Low-Temperature Systems

High-temperature commercial dishwashers operate with final rinse temperatures reaching 180°F (82°C), eliminating the need for chemical sanitizers during the rinse cycle. These units typically require a commercial dishwasher booster heater to achieve proper sanitization temperatures, especially when the incoming water temperature falls below 140°F.

Low-temperature systems operate with cooler rinse water but require commercial dishwasher and sanitizer chemical injection systems to achieve proper sanitization. The chemical dispensing systems automatically dose chlorine-based sanitizers at precisely 50-100 ppm during the final rinse cycle.

Commercial Dishwasher Categories by Capacity

Under-counter commercial dishwashers handle 20-40 racks per hour and work well for smaller establishments like coffee shops and sandwich bars. These compact units often integrate with commercial dishwasher and sink configurations to maximize limited space.

Single tank door-type machines process 40-60 racks hourly and represent the most common choice for mid-sized restaurants. The commercial dishwasher bench height typically measures 34-36 inches to align with standard prep table heights.

Conveyor dishwashers handle 100-300+ racks per hour for high-volume operations. These systems often require commercial dishwasher and dryer combinations or separate drying stations to manage the continuous output of clean dishware.

A Hobart commercial dishwasher showcasing its ENERGY STAR certification

Essential Commercial Dishwasher Accessories and Components

Dish Handling Systems

Commercial dishwasher baskets come in multiple configurations including full-size, half-size, cup racks, and flatware baskets. Proper basket selection impacts both washing efficiency and dishware protection during the cleaning cycle.

Commercial dishwasher basket trolley systems significantly improve workflow efficiency by allowing staff to transport multiple racks simultaneously. These mobile units typically accommodate 10-20 standard dishwasher racks and feature locking casters for stability during loading and unloading operations.

A stainless steel commercial dishwasher basket trolley with a blue plastic basket on top, designed for efficient transport of dish racks

The trolley design I’ve found most effective includes adjustable shelf spacing to accommodate various rack heights and a drip tray system to contain residual water during transport.

Water Management Components

Commercial dishwasher air gap devices prevent contaminated water from back-siphoning into the potable water supply. These simple but critical components mount on the dishwasher or nearby wall and create a physical separation between the drain line and water supply.

Commercial dishwasher backflow preventer assemblies provide additional protection against cross-contamination. Installation typically requires a licensed plumber and annual testing to ensure proper operation.

Schematic diagram of commercial dishwasher plumbing installation showing hose connections, tailpieces, and waste pipe fittings under a kitchen sink

Commercial dishwasher booster pump systems maintain adequate water pressure when municipal supply pressure falls below manufacturer specifications. Most commercial units require minimum 20-25 PSI dynamic pressure for proper operation.

Chemical Dispensing Systems

Modern commercial dishwasher auto chlor systems automatically proportion detergent and sanitizer based on water flow and temperature. These systems reduce chemical waste while ensuring consistent cleaning and sanitization results.

A dual chemical dispenser unit for dishwashing liquid and liquid sanitizer, featuring separate controls and clearly labeled inputs for commercial dishwasher systems

The dual-dispenser configuration shown provides separate controls for wash and rinse chemicals, allowing operators to adjust concentrations based on soil levels and local water conditions.

Electrical Requirements and Energy Efficiency

Power Requirements by Dishwasher Type

Commercial dishwasher amperage requirements vary significantly by machine type and features:

- Under-counter units: 15-30 amps at 208-240V

- Door-type machines: 30-50 amps at 208-240V

- Conveyor systems: 50-100+ amps at 208-240V or 480V

Commercial dishwasher amps calculations must account for booster heaters, which can add 15-40 amps depending on capacity requirements. Always verify electrical service capacity before equipment selection.

ENERGY STAR Efficiency Standards

Energy efficient commercial dishwashers meeting ENERGY STAR Version 3.0 requirements demonstrate measurable operational savings. Based on testing data, qualified units use approximately 40% less energy and 50% more water efficiently than standard models.

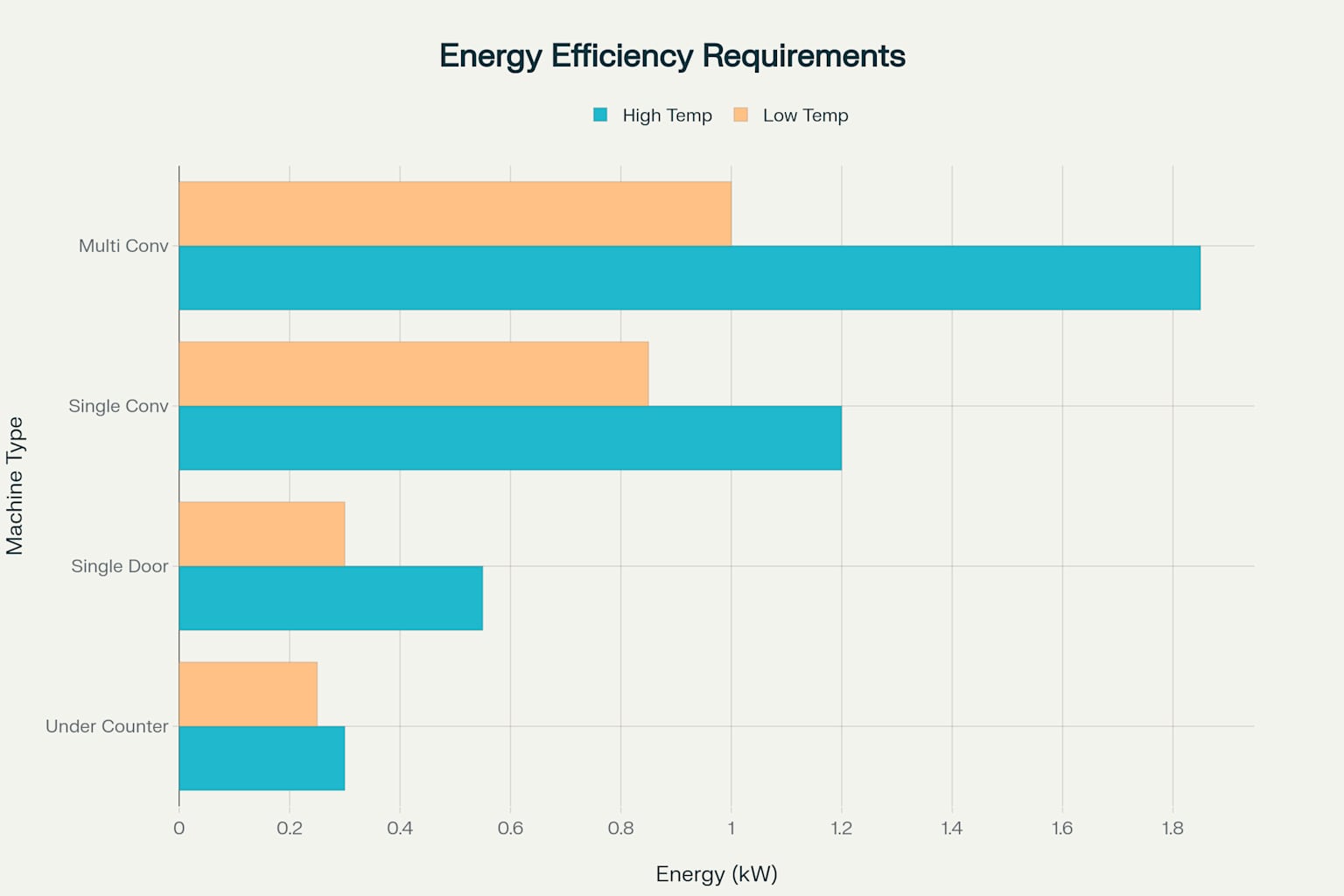

ENERGY STAR Efficiency Requirements: High Temperature vs Low Temperature Commercial Dishwashers

The efficiency comparison reveals that conveyor-type machines generally offer better water efficiency per rack, while under-counter units excel in energy efficiency for lower-volume operations.

Installation Considerations and Compliance

Plumbing Installation Requirements

Proper commercial dishwasher installation requires coordination of water supply, drainage, and chemical feed systems. The commercial dishwasher break tank serves as an indirect drainage connection, preventing potential contamination of the dishwasher’s internal systems.

Plumbing and electrical connections for a commercial dishwasher booster heater

This installation demonstrates the complexity of integrating booster heaters with existing plumbing systems. The pressure gauges and temperature controls ensure optimal operating conditions while the floor drain provides secondary containment for any equipment leaks.

ADA Compliance Considerations

Commercial dishwasher ADA compliance focuses on controls placement and operational accessibility. Control panels should mount no higher than 48 inches above floor level, and door handles must require no more than 5 pounds of force to operate.

Chemical Systems and Sanitization

Sanitizer Integration Systems

Commercial dishwasher and sanitizer integration requires precise chemical injection timing and concentration control. Low-temperature systems typically inject sodium hypochlorite solution at 50-100 ppm during the final rinse cycle.

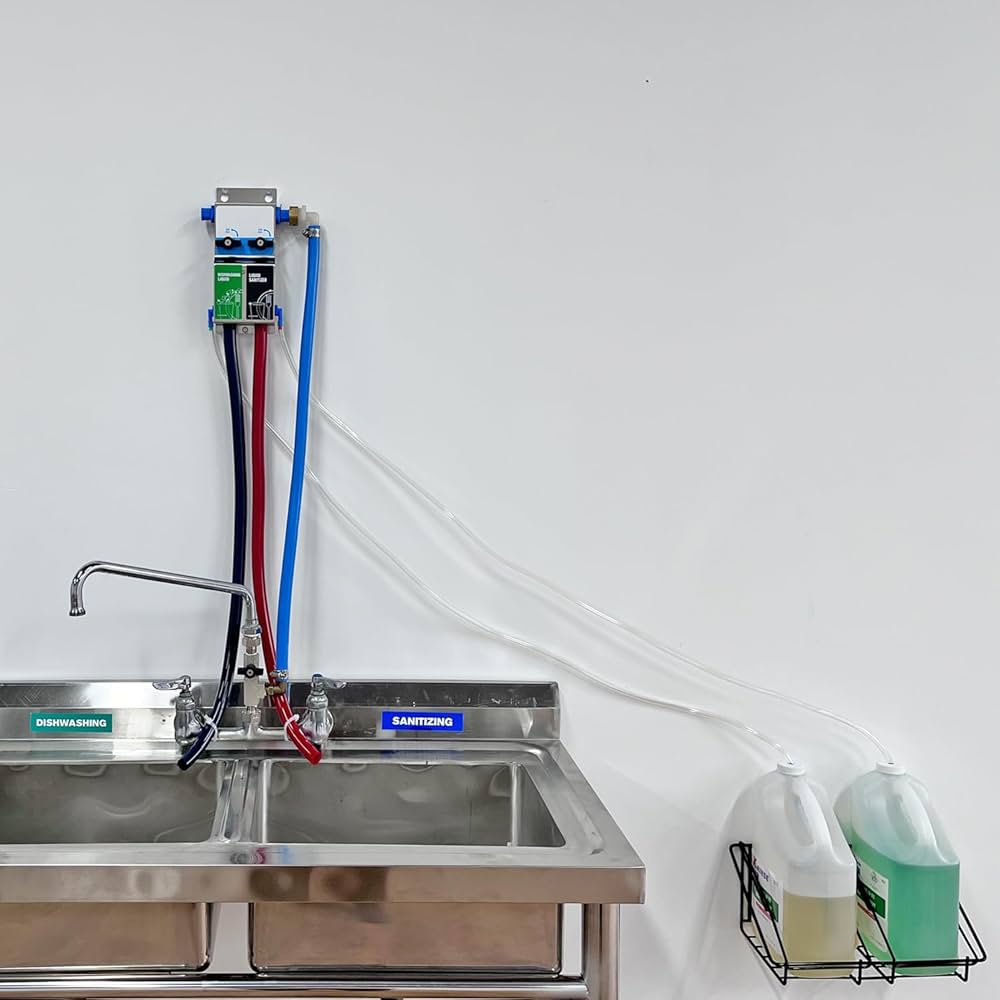

A commercial two-compartment sink with a wall-mounted chemical dispenser system for dishwashing and sanitizing

This two-compartment sink configuration with integrated chemical dispensing demonstrates how manual washing and machine washing can complement each other in commercial operations. The separate dishwashing and sanitizing compartments ensure proper chemical concentrations for each process step.

Water Quality Management

Hard water conditions require commercial dishwasher booster heater systems with built-in scale prevention or external water softening equipment. Calcium buildup reduces heat transfer efficiency and can damage heating elements over extended operation.

Maintenance and Operational Best Practices

Daily Maintenance Procedures

Commercial dishwasher maintenance begins with proper end-of-shift procedures including tank draining, filter cleaning, and chemical tank refilling. Wash and rinse arms require weekly removal and cleaning to prevent food particle accumulation.

Troubleshooting Common Issues

Temperature-related problems often trace to commercial dishwasher booster heater malfunctions or inadequate incoming water temperature. Proper diagnosis requires checking both water supply temperature and booster heater operation before assuming equipment failure.

Chemical dispensing issues typically result from clogged injection lines, empty chemical containers, or faulty dilution ratios. Regular inspection of commercial dishwasher accessories including dispensing pumps and chemical lines prevents most operational disruptions.

Purchasing and Specification Considerations

Equipment Selection Factors

Commercial dishwasher buy decisions should prioritize long-term operational costs over initial purchase price. Energy-efficient models meeting ENERGY STAR requirements typically recover their higher initial cost through reduced utility expenses within 2-3 years.

Commercial dishwasher brand names like Hobart, Jackson, CMA, and Champion each offer different strengths in reliability, service support, and feature sets. Local service availability often proves more important than specific brand preference for ongoing operational success.

Space Planning and Integration

Commercial dishwasher bench integration requires careful attention to workflow patterns and ergonomic considerations. Dirty dish entry and clean dish exit points should minimize cross-traffic and reduce recontamination risks.

Commercial dishwasher basket trolley staging areas need adequate space for both soiled and clean dish storage. Plan minimum 4-foot aisles around dishwashing equipment to accommodate trolley movement and maintenance access.

A stainless steel commercial dishwasher rack trolley with multiple shelves and casters

Conclusion

Successful commercial dishwasher operation depends on understanding the interconnected nature of water systems, chemical dispensing, energy management, and maintenance procedures. From commercial dishwasher air gap protection to commercial dishwasher booster pump sizing, each component contributes to overall system performance and regulatory compliance.

The investment in proper equipment selection, installation, and maintenance pays dividends through reduced labor costs, improved sanitation outcomes, and enhanced operational efficiency. Whether specifying systems for new construction or upgrading existing facilities, prioritizing energy efficiency and proper accessory integration ensures long-term operational success in commercial foodservice environments.