The implementation of commercial dishwasher solutions in Australian school cafeterias represents a critical infrastructure decision that impacts food safety, operational efficiency, and environmental sustainability across the education sector. This comprehensive analysis examines the current landscape of dishwashing technologies available to Australian schools, drawing from extensive industry experience, regulatory frameworks, and real-world implementation case studies to provide actionable insights for education administrators and facilities managers.

Current State of School Dishwashing Operations in Australia

Australian schools face unique challenges in their cafeteria operations, with varying student populations, diverse menu offerings, and stringent food safety requirements that must be balanced against budgetary constraints. The evolution from traditional manual washing systems to automated commercial dishwashers has become increasingly necessary as schools serve more diverse food options beyond the historical “pies and sausage rolls” model.

The transition to modern dishwashing solutions is driven by several critical factors including enhanced food safety compliance, labor efficiency improvements, and environmental sustainability goals. Research indicates that only 7% of schools in some Australian jurisdictions utilize commercial dishwashers, significantly lower than other developed nations where adoption rates range from 70-90%. This disparity highlights substantial opportunities for improvement in Australian school food service operations.

Food Safety and Regulatory Framework

Australian school canteens operate under stringent regulatory frameworks established by Food Standards Australia New Zealand (FSANZ), with specific requirements varying across states and territories. School canteens are classified as Class 2 food premises in most jurisdictions, requiring comprehensive food safety programs and certified supervision.

The implementation of Standard 3.2.2A has introduced mandatory food safety management tools for school canteens, including requirements for certified Food Safety Supervisors by December 2024 in New South Wales. These regulations mandate specific temperature controls for washing and sanitizing, with commercial dishwashers required to achieve wash temperatures of 150-160°F and rinse temperatures of 180°F for high-temperature sanitization.

Commercial dishwashers provide automated compliance with these requirements through built-in monitoring systems, thermostops, and digital temperature controls that ensure consistent sanitization standards. Manual washing operations frequently fail to meet these standards, with studies showing that manual washing often falls below required temperatures and sanitization protocols.

Technology Overview and Equipment Categories

The Australian market offers diverse commercial dishwasher technologies specifically designed for educational environments, ranging from compact undercounter units to high-capacity conveyor systems. Understanding the appropriate technology for specific school requirements is essential for successful implementation and long-term operational success.

Undercounter Dishwashers for Small Operations

Undercounter dishwashers represent the entry-level solution for smaller Australian schools, particularly suitable for primary schools with 25-75 students and teacher lounges. These compact units fit standard kitchen counter configurations while providing professional-grade washing capabilities with capacities of 25-40 racks per hour.

Leading models in the Australian market include the Classeq C500 series, which features Bluetooth connectivity and energy-saving standby modes specifically beneficial for school environments with intermittent usage patterns. The Winterhalter UC series offers specialized glass care capabilities important for schools serving milk and juice programs.

Door-Type Dishwashers for Medium-Volume Operations

Door-type dishwashers serve as the optimal solution for most Australian primary and secondary schools with 50-300 students, offering enhanced capacity while maintaining reasonable space requirements. These units can be configured as corner or straight-through installations, providing flexibility for diverse kitchen layouts common in educational facilities.

The Hobart CXeH door-type dishwasher exemplifies this category with ventless operation capabilities that eliminate expensive hood installation requirements, significantly reducing implementation costs for schools. Rhima’s DR59 passthrough model offers unique cold-water operation capabilities, particularly valuable in regions with limited hot water infrastructure.

High-Capacity Conveyor Systems

Large secondary schools and centralized food service operations require rack conveyor or flight-type dishwashers capable of processing 100-500 racks per hour. The MEIKO M-iQ series provides energy recovery technology that can reduce operating costs by up to 30%, making these high-capacity systems economically viable for large-scale operations.

These systems typically require significant infrastructure investments including three-phase electrical connections, enhanced drainage, and potentially ventilation systems. However, the operational efficiencies achieved through automated soil removal and energy recovery technologies often justify the initial investment for high-volume operations.

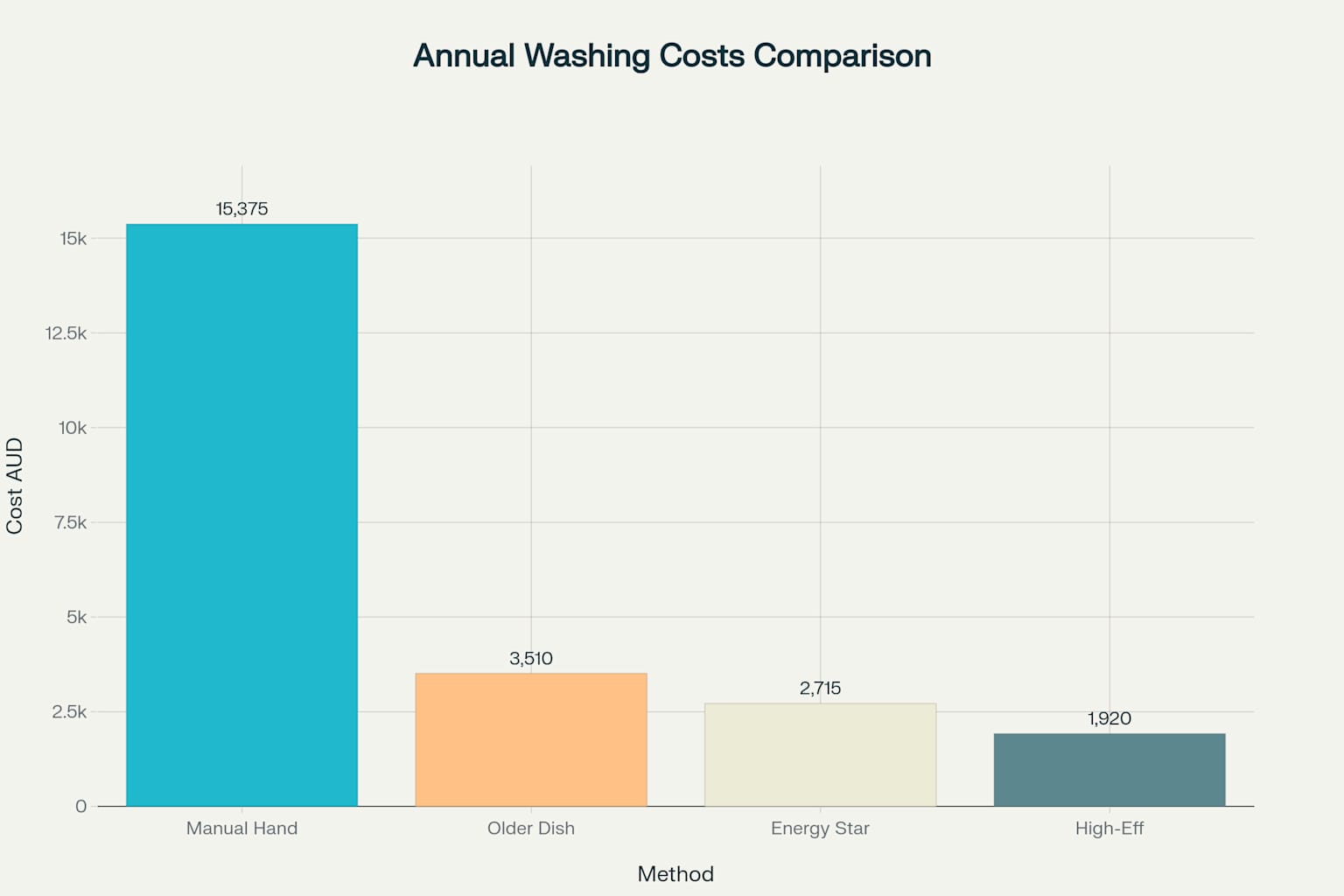

Annual Operating Costs Comparison for Different Dishwashing Methods in Australian Schools

Economic Analysis and Return on Investment

The financial implications of implementing commercial dishwasher solutions in Australian schools extend beyond initial equipment costs to encompass operational savings, labor efficiency improvements, and environmental benefits. Comprehensive cost analysis reveals compelling economic justification for dishwasher implementation across all school sizes.

Capital Investment and Payback Analysis

Investment requirements for school dishwasher solutions vary significantly based on equipment type and installation complexity, ranging from $3,000 for basic undercounter units to over $60,000 for high-capacity flight systems. However, the rapid payback periods achieved through operational savings make these investments financially attractive for most educational institutions.

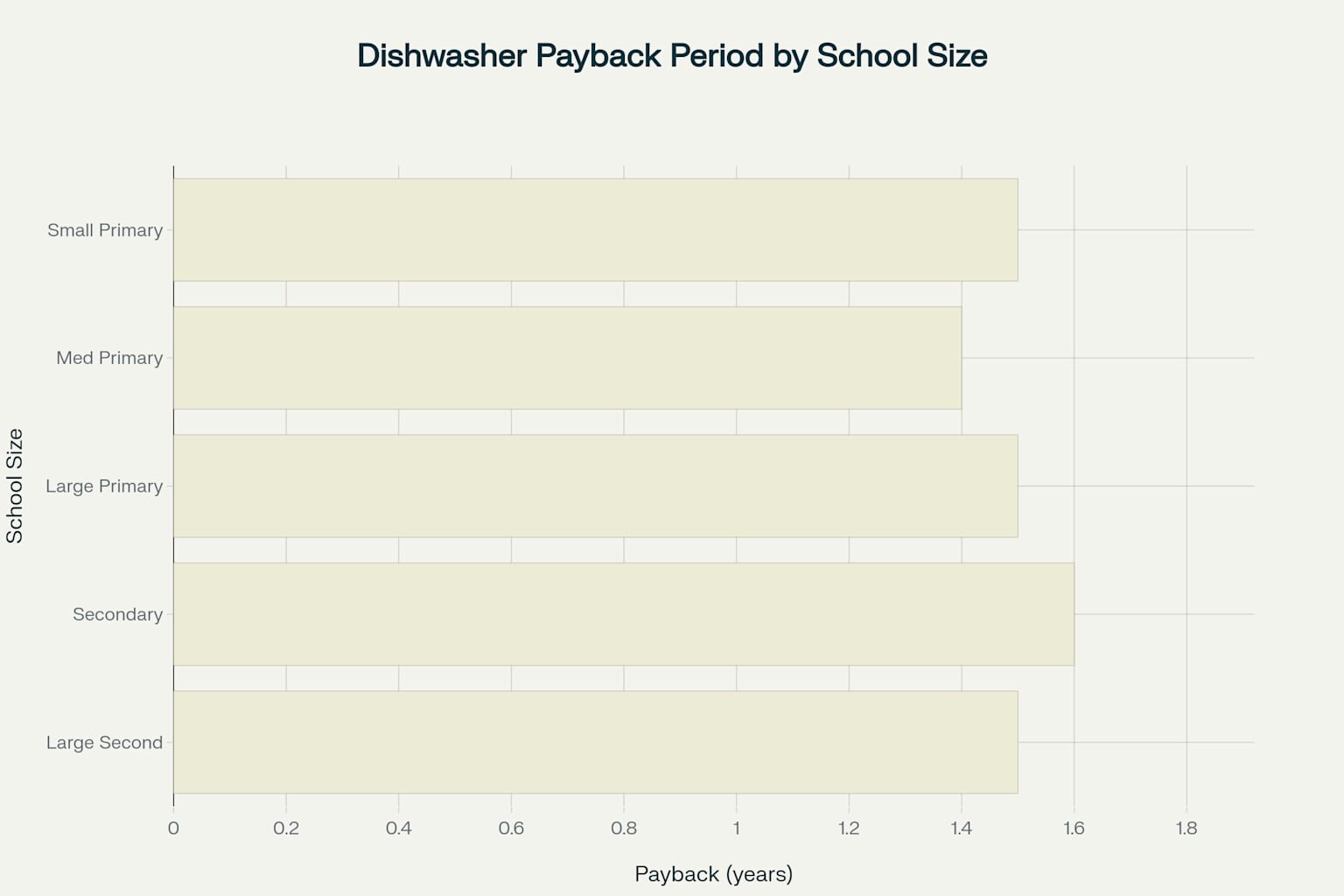

Dishwasher Investment Payback Periods for Australian Schools by Size

Analysis of Australian school implementations demonstrates payback periods ranging from 1.4 to 1.6 years across different school sizes, with medium-sized primary schools achieving the most favorable returns due to optimal utilization of equipment capacity. These calculations include equipment costs, installation expenses, and reusable ware investments offset by savings from eliminated disposable purchases and reduced labor requirements.

Operational Cost Comparisons

The transition from manual washing or disposable ware programs to automated dishwashing delivers substantial ongoing operational savings through reduced water consumption, energy efficiency, and labor optimization. Modern commercial dishwashers use as little as 4 liters of water per rack compared to 75 liters required for manual washing, representing a 95% reduction in water consumption.

Energy efficiency improvements are equally significant, with high-efficiency commercial dishwashers consuming only 0.4 kWh per rack versus 2.5 kWh for manual washing operations. These efficiency gains translate to annual operating cost reductions from $4,125 for manual washing to $420 for high-efficiency commercial systems, excluding labor cost considerations.

Labor cost analysis reveals additional substantial savings through reduced washing time requirements and improved workflow efficiency. Commercial dishwashers reduce processing time from 15 minutes per rack for manual washing to 2 minutes for automated systems, enabling staff reallocation to food preparation and service activities.

Australian Supplier Landscape and Product Selection

The Australian commercial dishwasher market features established local distributors and service networks supporting international manufacturers with proven track records in educational applications. Understanding supplier capabilities, product features, and service support is crucial for successful long-term implementations.

Local Market Leaders

Rhima Australia, headquartered in Melbourne, provides comprehensive commercial dishwasher solutions with national service coverage and specialized school-focused products. Their DR59 passthrough dishwasher offers unique cold-water operation capabilities and integrated water softening systems particularly valuable for Australian conditions.

Winterhalter Australia offers extensive educational sector experience with user-friendly controls and plastic-cup friendly designs essential for schools serving young children. Their UC and PT series dishwashers feature intuitive operation suitable for volunteer and part-time staff common in school canteen operations.

Classeq Australia, based in Sydney, has developed modern connected dishwasher solutions with Bluetooth connectivity and energy-saving features specifically beneficial for educational environments. Their C500 and D500 series offer excellent value propositions for medium-volume school applications.

Specialized School Features

Leading manufacturers have developed specific features addressing unique school operational requirements including enhanced safety systems, simplified controls, and durability for high-volume daily use. Thermo-stop technology prevents cycle completion until proper sanitization temperatures are achieved, ensuring consistent food safety compliance.

User-friendly controls with color-coded displays and preset programs enable effective operation by volunteers and part-time staff without extensive training requirements. Bluetooth connectivity and remote monitoring capabilities allow for proactive maintenance and operational optimization.

Implementation Best Practices and Practical Considerations

Successful dishwasher implementation in Australian schools requires careful planning, stakeholder engagement, and systematic approach to change management. Drawing from successful implementations across the country, several critical success factors emerge for educational administrators.

Pre-Implementation Assessment

Comprehensive assessment of existing operations, infrastructure requirements, and stakeholder needs forms the foundation for successful dishwasher implementation.

This assessment must consider current student enrollment, projected growth, peak service volumes, and existing kitchen infrastructure capabilities.

Infrastructure evaluation should encompass electrical capacity, plumbing systems, ventilation requirements, and integration with existing workflow patterns. Many Australian schools require electrical upgrades to support commercial dishwasher installation, particularly for higher-capacity units requiring three-phase power connections.

Space planning must consider equipment dimensions, clearance requirements, and workflow optimization to ensure efficient integration with existing kitchen operations. Door swing patterns, delivery access, and service accessibility are frequently overlooked factors that can significantly impact implementation success.

Staff Training and Change Management

Effective staff training programs are essential for successful transition to commercial dishwashing operations, particularly in school environments relying on volunteer and part-time staff. Training must encompass food safety principles, equipment operation, chemical handling, and maintenance procedures to ensure consistent performance.

The implementation of HACCP principles and temperature monitoring procedures requires systematic approach to staff education and ongoing compliance verification. Commercial dishwasher manufacturers typically provide comprehensive training programs as part of installation services, but ongoing reinforcement and refresher training are necessary for long-term success.

Change management strategies should address resistance to operational modifications and emphasize benefits including improved working conditions, enhanced food safety, and environmental sustainability. Student education programs can support implementation by promoting proper ware sorting and sustainability awareness.

Environmental Impact and Sustainability Benefits

The environmental benefits of commercial dishwasher implementation extend beyond immediate operational efficiencies to encompass waste reduction, resource conservation, and educational opportunities for sustainability awareness. Australian schools are increasingly recognizing these benefits as part of broader environmental education initiatives.

Waste Reduction Achievements

Transition from disposable to reusable ware programs supported by commercial dishwashers achieves substantial waste reduction with measurable environmental benefits. Case studies from California schools demonstrate waste reduction of over 8,000 pounds annually through reusable ware programs, with similar benefits achievable in Australian contexts.

The elimination of single-use plastic trays, cutlery, and containers directly supports Australian schools’ sustainability goals while providing tangible examples for student environmental education. Waste reduction also generates cost savings through reduced disposal fees and container purchasing requirements.

Resource Conservation Impact

Modern commercial dishwashers deliver significant water and energy conservation compared to manual washing systems, supporting Australian schools’ environmental responsibility goals. Water usage reductions of up to 95% compared to manual washing systems provide substantial environmental benefits while reducing utility costs.

Energy efficiency improvements through heat recovery systems, optimized cycle programming, and standby mode operation contribute to reduced carbon footprint and operational sustainability. Some models incorporate drain water energy recovery systems that can reduce energy consumption by up to 20% through heat recycling.

Case Studies and Implementation Success Stories

Real-world implementation experiences from Australian and international schools provide valuable insights for educational administrators considering dishwasher investments. These case studies demonstrate both challenges and benefits realized through systematic implementation approaches.

Australian Implementation Examples

Hillbrook Anglican College in Brisbane successfully implemented a comprehensive kitchen upgrade including commercial dishwashing equipment to support their transition from traditional canteen food to café-style fresh meals. The implementation required careful coordination with volunteer parent helpers and systematic training to ensure consistent operation.

The college’s experience highlights the importance of selecting equipment with user-friendly controls and safety features suitable for diverse operator skill levels. Their success demonstrates the feasibility of implementing commercial dishwashing solutions in schools relying on volunteer labor support.

International Best Practices

Roncalli High School in Wisconsin provides a compelling case study of long-term dishwasher performance, with their Hobart C-81 conveyor dishwasher operating successfully for over 55 years with minimal maintenance requirements. This experience demonstrates the potential for exceptional equipment longevity when properly maintained and operated.

Franklin Elementary School in California achieved $25,000 in net annual savings through their transition to reusable ware supported by donated commercial dishwasher equipment. Their implementation eliminated 111,000 disposable trays annually while reducing labor requirements through automated washing processes.

Conclusion and Strategic Recommendations

The implementation of commercial dishwasher solutions in Australian school cafeterias represents a strategic investment opportunity with compelling financial, operational, and environmental benefits. The evidence clearly demonstrates that properly selected and implemented dishwashing systems deliver rapid payback periods, substantial operational savings, and enhanced food safety compliance across all school sizes.

Australian schools should prioritize dishwasher implementation as part of comprehensive facility modernization programs, recognizing both immediate operational benefits and long-term strategic advantages. The combination of regulatory compliance requirements, economic benefits, and environmental sustainability makes commercial dishwashing an essential infrastructure investment for forward-thinking educational institutions.

Success requires systematic approach to needs assessment, supplier selection, implementation planning, and change management to ensure optimal outcomes. Schools should engage qualified consultants and leverage manufacturer expertise to navigate technical requirements, regulatory compliance, and operational optimization for their specific circumstances.

The compelling evidence supports immediate action for Australian schools to evaluate and implement appropriate commercial dishwashing solutions as a fundamental component of modern, efficient, and sustainable food service operations. The technology, supplier support, and proven benefits are readily available to transform school cafeteria operations across the country.