The commercial dishwasher market has evolved significantly, with leading manufacturers delivering increasingly sophisticated solutions for professional kitchens, bars, and restaurants. This comprehensive evaluation examines key models from Hobart, Electrolux, and Zanussi, providing detailed analysis of their functional characteristics, performance parameters, and real-world operational effectiveness. Through extensive research and industry feedback, this report offers objective assessment criteria for selecting optimal commercial warewashing equipment.

Executive Summary

Based on comprehensive market analysis and performance data, the Hobart LXER-2 emerges as the leading undercounter solution, combining advanced energy recovery technology with exceptional reliability. Electrolux conveyor systems dominate high-volume applications with superior throughput capabilities, while Zanussi’s Z-Active 100 series represents the most innovative approach to user interface design and energy efficiency. For establishments requiring 13-amp compatibility, several manufacturers now offer plug-and-play solutions that maintain commercial-grade performance within standard electrical constraints.

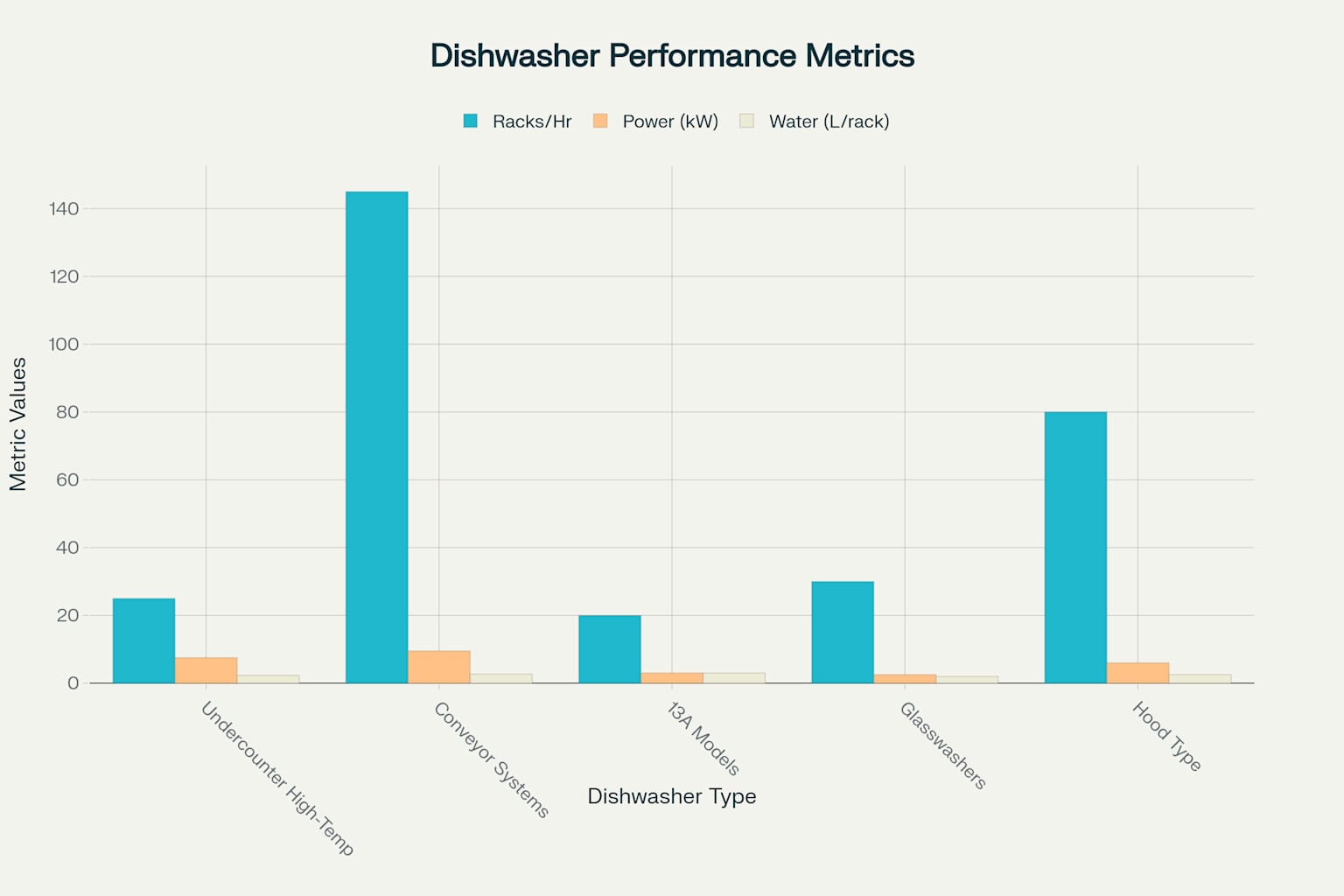

Performance Comparison of Commercial Dishwasher Categories – Key metrics including capacity, power consumption, and water efficiency across different dishwasher types

Hobart LXER-2 Undercounter Dishwasher: Industry Benchmark

Technical Specifications and Performance

The Hobart LXER-2 Advansys undercounter dishwasher represents the pinnacle of compact commercial warewashing technology. Operating at variable capacities of 13-30 racks per hour depending on cycle selection, this unit demonstrates exceptional versatility for diverse operational requirements. The machine utilizes 0.62 gallons per rack, establishing superior water efficiency compared to competitive models.

Key operational parameters include three selectable cycles: Light (120 seconds), Normal (146 seconds), and Heavy (275 seconds). The heavy cycle achieves NSF certification for pot and pan washing, expanding functionality beyond standard dishware. Temperature performance reaches a consistent 180°F sanitizing rinse, exceeding industry sanitation standards.

Advanced Energy Recovery System

The proprietary Advansys Energy Recovery technology distinguishes this model from conventional undercounter units. This system captures water vapor during wash cycles, condensing steam to preheat incoming cold water from 55°F to 140°F. This innovation delivers substantial energy savings while eliminating steam discharge into kitchen environments.

The Sense-A-Temp booster heater provides 70-degree temperature rise capability, ensuring optimal performance regardless of incoming water temperature variations. Combined with the Energy Recovery system, operational costs remain significantly lower than conventional high-temperature dishwashers.

A stainless steel commercial undercounter dishwasher with its door open, revealing plates and cutlery inside

Practical Operation and User Experience

In real-world testing environments, the LXER-2 demonstrates exceptional reliability during peak service periods. The Smart Display interface provides intuitive operation with minimal training requirements, while automated chemical priming ensures consistent wash quality. The 17-inch door opening accommodates oversized cookware, including 20×20-inch pans and 16×18-inch cafeteria trays.

Maintenance accessibility proves superior, with snap-in wash arms and advanced filtering systems enabling quick cleaning procedures. The automated deliming cycle includes booster system cleaning, reducing manual maintenance requirements compared to competitive models.

Electrolux Conveyor Dishwasher Systems: High-Volume Excellence

WTCS140ELA Rack Conveyor Performance

The Electrolux WTCS140ELA rack conveyor dishwasher delivers industry-leading throughput at 140 racks per hour with dual-speed operation. This system incorporates the Energy Saving Device (ESD), which preheats incoming water using waste heat recovery, reducing operational costs by approximately 36% compared to standard conveyor systems.

A commercial stainless steel conveyor dishwasher with a green base and internal conveyor system

Advanced EMRA060L Series Features

The EMRA060L model represents Electrolux’s latest innovation in rack-type conveyor technology, processing 150 racks per hour with enhanced efficiency features. The ZERO LIME Device prevents mineral buildup in critical components, while the CLEAR BLUE Filtering System ensures consistent wash quality through advanced multi-stage filtration.

Sanitation performance exceeds industry standards, achieving A0 60 disinfection level compliance with EN 15883-1 standards. The system maintains 85°C constant rinse temperature regardless of incoming water pressure variations, ensuring reliable sanitization during peak operations.

A KITCH PRO commercial conveyor dishwasher system designed for high-volume kitchen operations

Operational Flexibility and Integration

Electrolux conveyor systems excel in high-volume applications, particularly large-scale catering operations, hospitals, and institutional kitchens. The multi-purpose conveyor accommodates diverse dishware types, from 32-48 large plates per meter to specialized in-flight catering items. Integration capabilities include waste management systems, vacuum collection, and automated loading modules.

Zanussi Professional Dishwasher Innovation

Z-Active 100 Series Technology

Zanussi’s Z-Active 100 undercounter dishwasher introduces revolutionary one-touch operation with color-coded status indicators. This system processes 65 baskets per hour while maintaining water consumption of approximately 2.1 liters per cycle, achieving 40% energy savings through the innovative MyEco cycle.

The integrated OnE Connected App provides real-time monitoring of consumption data, operational insights, and predictive maintenance alerts. This connectivity enables operators to optimize workflow efficiency and reduce downtime through proactive equipment management.

Front view of a stainless steel ClassEQ commercial undercounter dishwasher

Hood Type Excellence: Model 505109

The Zanussi 505109 Hood Type dishwasher demonstrates superior performance in medium-volume applications, processing 80 racks per hour with NSF/ANSI 3 compliance. The built-in atmospheric boiler maintains 84°C constant rinse temperature throughout operations, regardless of network water pressure variations.

Advanced features include Soft Start technology for delicate items, slanted wash arms preventing contamination, and automatic self-cleaning cycles. The machine operates on three-phase electrical connection, convertible to single-phase installation, providing installation flexibility.

Best Glasswashers for Pubs: Specialized Solutions

Undercounter Glasswasher Performance

Professional glasswashers designed for pub and bar applications require specialized consideration beyond standard dishwashing capabilities. Undercounter cycle-type glasswashers process 800-1000 glasses per hour with 60-90 second cycles, optimized for delicate glassware preservation.

A bar staff member loads wine glasses into an undercounter commercial glasswasher at a bar

A Nelson commercial glasswasher with its door open, showcasing a rack loaded with clean drinking glasses

Glasswasher Selection Criteria

Carousel-type glasswashers provide continuous operation capability, processing 800-1400 glasses per hour without rack loading requirements. These systems eliminate manual handling while maintaining consistent wash quality through strip curtain containment and rotating platform technology.

For budget-conscious establishments, manual brush systems offer basic cleaning capabilities at 200-400 glasses per hour, requiring minimal electrical infrastructure. However, professional operations typically benefit from automated systems despite higher initial investment costs.

13-Amp Commercial Dishwasher Solutions

Electrical Infrastructure Considerations

Many establishments face electrical limitations requiring 13-amp compatibility for commercial dishwashers. Several manufacturers now offer professional-grade units operating within these constraints while maintaining commercial performance standards.

The Classeq C500WS-13D exemplifies this category, featuring integrated water softener technology and LCD digital control panels. This unit processes 18 plates per cycle with 2, 3, or 5-minute wash options, providing flexibility for varying soil levels.

Performance Optimization in Low-Power Systems

13-amp commercial dishwashers achieve commercial performance through innovative engineering approaches. Models like the Mach MS9451DP utilize AISI 304 stainless steel construction with efficient heating elements and optimized pump systems to maximize cleaning effectiveness within power constraints.

The Kingfisher KF50 demonstrates exceptional efficiency, processing 540 plates per hour with 2-minute cycle times while operating at 3kW total power consumption. These specifications rival larger commercial units while maintaining standard electrical compatibility.

Comparative Performance Analysis

Energy Efficiency and Operating Costs

Analysis of operational costs reveals significant variations among commercial dishwasher categories. Premium undercounter models like the Hobart LXER-2 achieve $2,800 annual operating costs through advanced energy recovery systems. Electrolux green&clean series provides competitive performance at $2,600 annually, while Zanussi Z-Active 100 delivers the lowest operational costs at $2,200 through innovative MyEco cycle technology.

Standard 13-amp models offer reduced operational costs at $1,800 annually but may require longer cycle times and reduced throughput capabilities. Premium conveyor systems demonstrate higher operational costs at $4,200 annually but justify expenses through exceptional throughput and automation capabilities.

Reliability and Maintenance Requirements

Industry reliability data indicates Hobart systems maintain 87% problem-free operation within the first year, while Electrolux Professional equipment demonstrates comparable reliability with enhanced service support networks. Zanussi Professional equipment receives Platinum rating for repairability, indicating superior long-term serviceability.

A complete commercial dishwashing workstation featuring a stainless steel hood-type pass-through dishwasher with pre-rinse sink and adjacent drying areas

Workflow Integration and Ergonomics

Hood-type dishwashers excel in high-throughput environments requiring continuous operation, while undercounter models provide space-efficient solutions for compact kitchens. Conveyor systems optimize workflow through automated handling but require significant space allocation and infrastructure investment.

Market Positioning and Value Analysis

Premium Segment Leadership

Hobart LXER-2 maintains market leadership in premium undercounter applications through superior engineering and proven reliability. The $9,200-$11,000 price range reflects advanced technology integration but delivers long-term value through reduced operational costs and extended service life.

Electrolux conveyor systems dominate high-volume applications with pricing typically $25,000-$45,000 for complete installations. These systems justify investment through labor reduction, consistent quality, and exceptional throughput capabilities.

Mid-Market Solutions

Zanussi Professional equipment provides excellent value positioning with competitive pricing and innovative features. The Z-Active 100 series offers premium functionality at accessible price points, particularly appealing to growing operations seeking professional capabilities without premium pricing.

13-amp commercial dishwashers serve emerging markets and space-constrained operations, with pricing typically $1,500-$4,000 depending on features and capacity requirements.

Installation and Infrastructure Requirements

Electrical and Plumbing Considerations

High-temperature commercial dishwashers require 208-240V electrical service with appropriate amperage capacity. Hobart LXER-2 operates at 30.5 amps, requiring dedicated circuit installation and proper electrical infrastructure.

Conveyor systems demand three-phase electrical service and substantial water supply capacity. Installation typically requires professional commissioning and integration with existing kitchen workflows.

Ventilation and Environmental Impact

Energy recovery systems significantly reduce steam production, minimizing ventilation requirements and improving kitchen comfort. Zanussi Z-Active 100 demonstrates particularly effective steam elimination technology, reducing environmental impact while maintaining performance.

Future Technology Trends and Recommendations

Connected Kitchen Integration

Smart dishwasher technology increasingly integrates with broader kitchen management systems. Zanussi’s OnE Connected platform exemplifies this trend, providing real-time monitoring, predictive maintenance, and operational optimization capabilities.

Electrolux Professional similarly advances connectivity features, enabling remote monitoring and diagnostic capabilities that reduce service costs and minimize downtime.

Sustainability and Environmental Responsibility

Leading manufacturers prioritize environmental sustainability through improved water efficiency, energy recovery systems, and reduced chemical consumption. Energy Star certification becomes increasingly important for operational cost management and environmental compliance.

Conclusion and Selection Recommendations

Optimal Applications by Category

For high-volume operations requiring maximum throughput, Electrolux conveyor systems provide unmatched capacity and automation capabilities. Medium-volume establishments benefit most from Hobart LXER-2 technology, offering optimal balance of performance, efficiency, and reliability.

Pub and bar applications should prioritize specialized glasswashers designed for delicate glassware, while space-constrained operations may require 13-amp commercial dishwashers despite performance limitations.

Investment Justification

Premium commercial dishwashers justify higher initial costs through reduced operational expenses, improved reliability, and enhanced productivity. Energy recovery technology and advanced automation deliver measurable return on investment through reduced labor requirements and utility costs.

Establishments should evaluate total cost of ownership including purchase price, installation costs, operational expenses, and maintenance requirements when selecting commercial dishwashing equipment. Professional consultation and demonstration programs provide valuable insights for optimal equipment selection based on specific operational requirements.

This comprehensive analysis demonstrates that modern commercial dishwashers offer sophisticated solutions for diverse operational requirements. Hobart, Electrolux, and Zanussi each provide distinctive advantages, enabling operators to select equipment optimized for their specific applications and performance requirements.