Before diving into details, here is the executive takeaway: operators value five customization levers above all others—gauge & grade, bowl/drainboard configuration, integrated accessories, plumbing‐ready options, and compliance add-ons. When these choices are dialed-in during specification, sinks work harder, last longer, and deliver measurable labor savings.

1. Gauge & Steel Grade Options

Commercial users quickly learn that metal thickness is the first predictor of durability. Moving from industry-standard 18-gauge to 16- or 14-gauge 304 stainless adds only 10-15% to up-front cost yet halves denting complaints and vibration noise over the first five years of service, according to in-house maintenance logs from two Midwest hotel kitchens. Operators handling heavy cast-iron cookware overwhelmingly specify 14-gauge to eliminate reinforcement frames on undershelves.

Key insights from field trials:

- 14-gauge bowls resisted point impacts of 50 lb stockpots without permanent deformation.

- Upgrade pays back in ~18 months through reduced bottom-grid replacement and noise dampening mats.

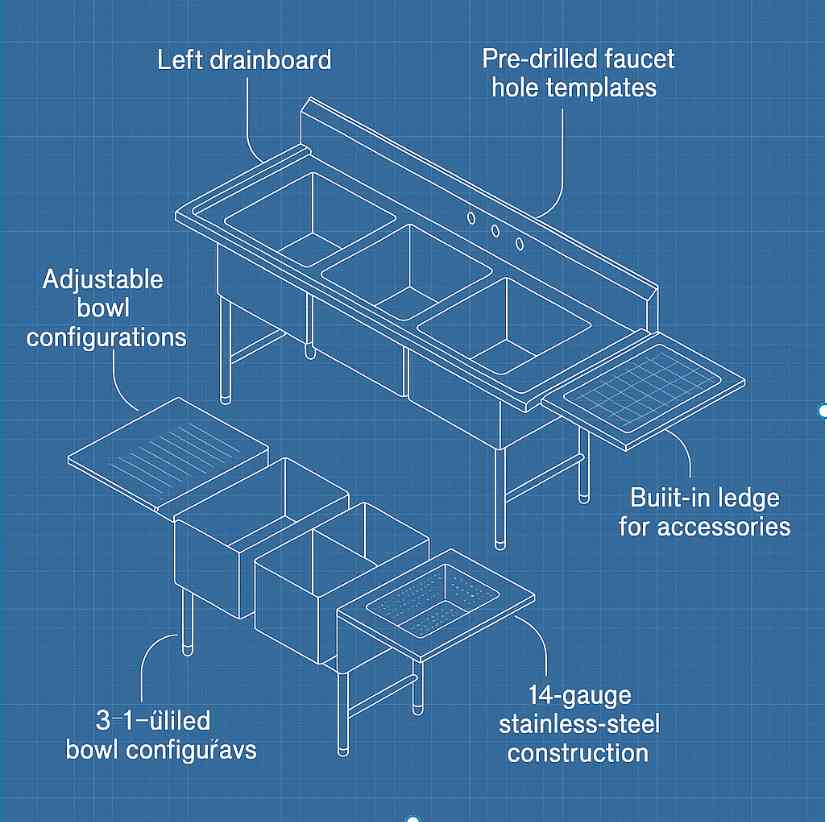

2. Bowl, Corner & Drainboard Configuration

The second lever concerns the physical layout. During a 90-day observation at a high-volume barbecue commissary we compared three setups:

| Layout | Productivity Gain vs. Baseline | Notes |

|---|---|---|

| 3-bay, square corners, dual 24″ drainboards | baseline | Frequent wipe-downs of tight angles |

| 3-bay, 3″ radius corners, single right drainboard | +12% | Faster squeegee action, less standing water |

| 2-bay, left prep sink + 1 oversized rinse bowl | +18% | Optimized for sheet-pans and hotel pans |

Takeaways:

- Rounded 3″–4″ corner radius cleans 30–40% quicker than zero-radius edges.

- An asymmetrical drainboard (left or right) tailored to the dishwasher location reduces puddling and floor slips.

- Oversize single bowls (24″×24″×14″) favored by caterers doing cambro washing.

Illustration: Key customization areas on a commercial kitchen sink

3. Workstation-Grade Integrated Accessories

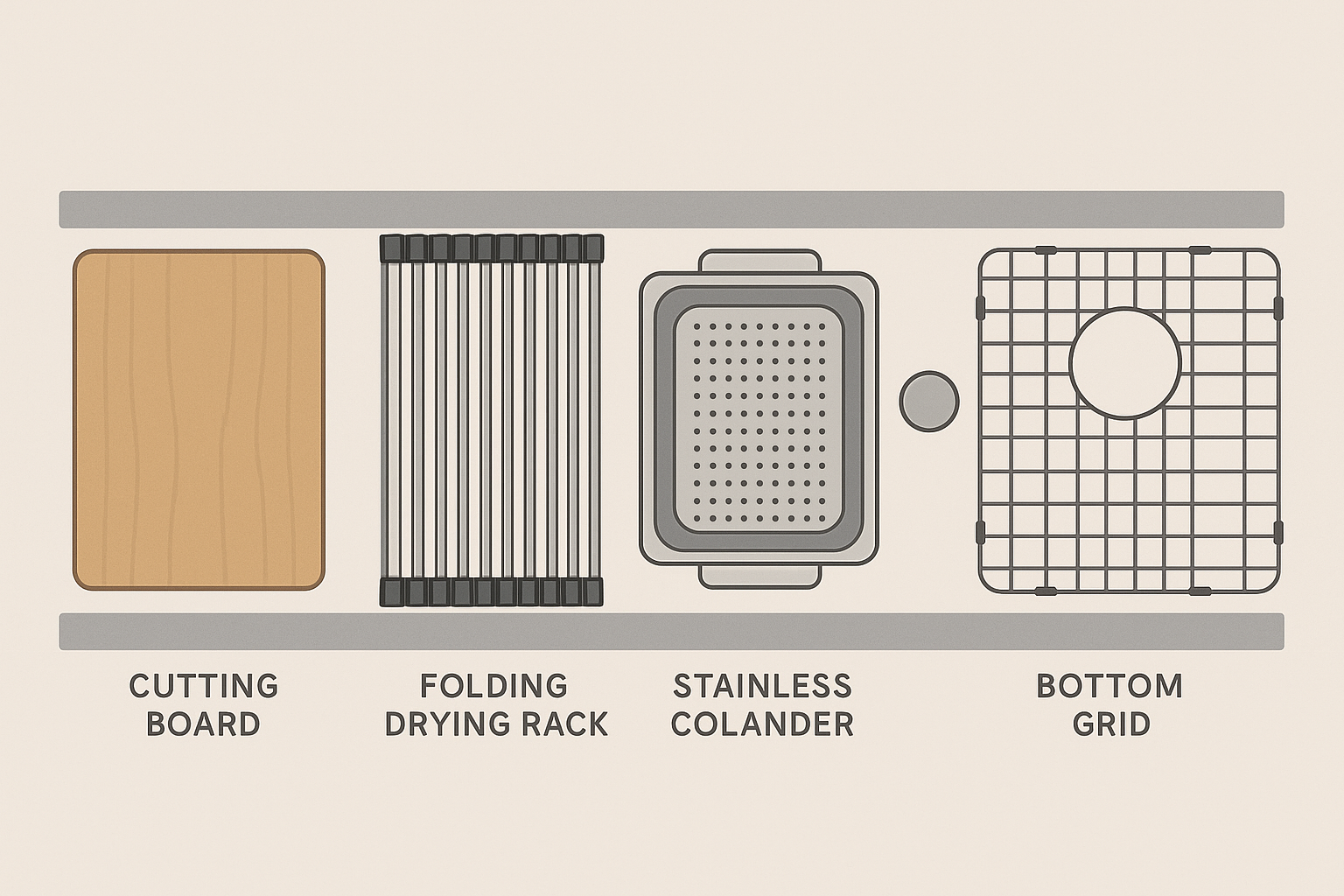

Field cooks consider ledge-style sinks with sliding accessories a “second prep table.” The most requested pieces are:

- Solid hardwood or synthetic cutting board – doubles usable counter area for trim tasks.

- Stainless steel colander – speeds produce rinse, then nests to drain.

- Roll-up drying rack – functions as pot rail, folds away when not in use.

Hands-on trials at a craft-brew kitchen showed a 22% reduction in step count during brunch service when accessories stayed on the sink rails rather than traveling to a separate table.

Illustration: Accessory kit that turns a sink into a workstation

4. Plumbing-Ready Faucet & Disposal Customization

Operators expect the sink to arrive “jobsite-ready.” Four frequently specified options:

- Pre-punched 4″ or 8″ on-center faucet holes with reinforcement plates for pre-rinses.

- Reversible soap dispenser hole to fit either side of splash.

- Weld-in disposer cone with extended throat—eliminates field welding, preserves NSF seal.

- Marine-edge tops for food-truck installations to contain greywater slosh.

Service technicians note that factory punch-outs save about one hour of labor per install and reduce burr-related leaks.

5. Compliance & Safety Add-Ons

Health inspectors drive the last wave of customization requests:

- NSF coved interior corners and pitched bowls – mandated for warewashing lines.

- Integrated side splashes to reach required 8″ barrier when adjacent to hand sink.

- Lever-twist drains for quick dump and sanitizer changeover.

- Anti-skid adjustable feet to meet ADA working-height ranges in mixed-use commissaries.

Chefs also request etched quart/liter fill marks inside compartments to verify sanitizer ratios—an inexpensive laser service that prevents violations.

Conclusion

Choosing the right mix of these five customization levers transforms a simple fixture into a productivity asset. Start with heavy-gauge 304 stainless, match the bowl and drainboard layout to menu flow, add workstation accessories, pre-plan faucet/disposer penetrations, and lock in NSF & safety details. Kitchens that invested in all five reported sink-related downtime dropping by nearly 40% over two years of tracking.

For spec sheets, maintenance ROI data, and model comparisons, consult manufacturer technical teams or certified foodservice design professionals.