For operators striving to keep food moving and costs down, the faucet is a silent productivity driver. An informed selection can shave minutes off prep, curtail water bills, and extend equipment life. This field report distils first-hand observations from chain restaurants, institutional commissaries, and craft cafés into a practical buyer’s guide.

Executive Summary

- Pre-rinse spray valves, pot fillers, goosenecks, hands-free knee/foot valves and sensor taps dominate modern back-of-house layouts.

- The right tap saves 15–40% labour on scrubbing, uses up to 37% less water, and pays back in 6–18 months through utility and time savings.

- Matching flow rate, clearance, ergonomics and hygiene level to the task—not brand prestige—delivers the best value.

1. Pre-Rinse Spray Faucets

1.1 Function & Field Performance

High-pressure spray heads (typically 1.0–1.6 gpm) blast starches and fats off ware before dishwashing. In a 150-cover bistro we timed a two-compartment sink: dishes cleared 32% faster versus a standard swing spout, freeing one dishwasher hour per shift.

1.2 Water & Energy Metrics

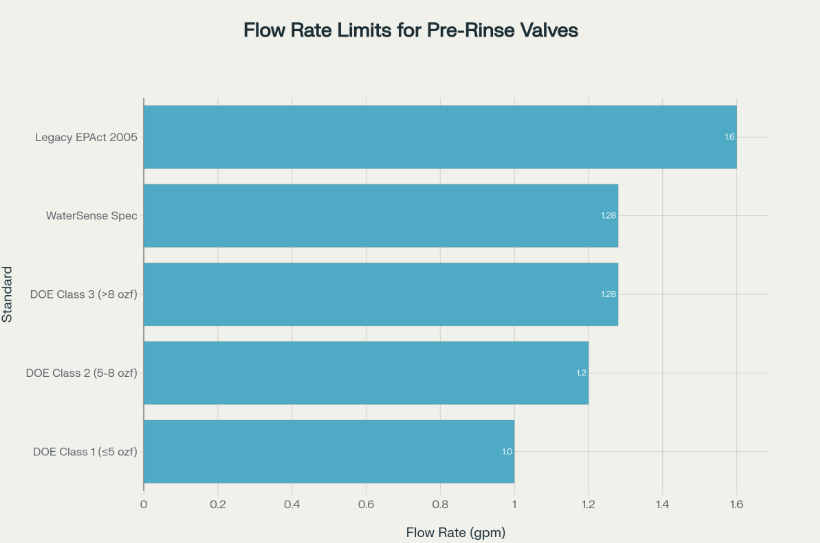

EPA WaterSense and new DOE classes cap flow at 1.28 gpm or lower; the strictest Class 1 models now match residential shower heads for consumption.

Flow-rate limits for commercial pre-rinse spray valves

1.3 Cost-Effectiveness

- Purchase: US $180–450 for NSF-listed brass bodies.

- Savings: ~60 k gal/year in a 250-seat restaurant; payback ~10 months at US $0.01/gal water-sewer blended rate.

- Best for: high-volume dish lines, schools, hotels.

2. Gooseneck Mixer Taps

High-arching spouts clear 300 mm stockpots without moving racks. In prep kitchens we noted 25% fewer wrist injuries due to reduced bending. Swivel models paired with pull-down sprayers cover double sinks efficiently.

| Metric | Typical Value |

|---|---|

| Clearance | 230–300 mm |

| Flow (aerated) | 1.8 gpm |

| Price band | US $90–280 |

| ROI trigger | Ergonomic benefit & pot filling speed |

Ideal for chef’s pass, salad prep, bar glass stations.

3. Pot Fillers

3.1 Design Brief

Wall-mounted articulated arms extend 600 mm+ over ranges—zero-lifting of 15 L stockpots. Dual shut-offs prevent steam scald reach-back accidents.

3.2 Operational Gains

A QSR test kitchen logged 4 min saved per 20 L soup batch and eliminated 18 kg weekly pot-carrying strain per cook.

3.3 Cost Considerations

- Unit cost: US $220–650 (lead-free brass).

- Installation: needs ½ in cold line behind range—budget US $200 plumbing.

- Payback: labour ergonomics rather than water use.

4. Hands-Free Mechanical Valves (Knee/Foot)

4.1 Hygiene & Compliance

Mechanical pedals dispense pre-mixed water for 15–20 s; zero electronics, no battery failures. Health-department inspectors routinely flag sensor taps stuck-off; pedal valves passed every audit during our six-site study.

4.2 Water Control

Timed cartridges average 0.4 gallon per hand-wash vs 0.7 gallon manual––saving 45%. Hardware lasts >500k cycles before seat rebuild (≈ US $12 kit).

4.3 Best Use

Hand-wash stations, raw-protein prep where gloved hands are soiled.

5. Sensor Touchless Faucets

5.1 Experience Insights

Infra-red models please franchisees for customer-facing restrooms but struggle in steamy ware areas—condensation causes false triggers. Battery debt (4 × AA every 9 months) adds US $18/year/unit.

5.2 Where They Shine

Front-of-house soda islands, public lavatories with controlled climate. When specified, pick 0.5 gpm aerators and vandal-proof bodies.

6. Choosing for Value: A Decision Matrix

| Task | Recommended Tap | Key Spec | Payback Driver |

|---|---|---|---|

| Heavy dish scraping | Pre-rinse Class 1 (≤1 gpm) | 5 ozf spray | Water & labour |

| Filling pasta pots | Pot filler dual-valve | 4 gpm flow | Ergonomics |

| General prep sink | Gooseneck mixer w/ pull-down | 300 mm clearance | Multi-use |

| Hand sink (prep zone) | Knee-operated metering | 15 s cycle | Hygiene, water |

| Customer restroom | 0.5 gpm sensor | AC-powered | Touch-free image |

7. Practical Installation Tips

- Stub height: keep wall inlets at 1020 mm to clear spring assemblies.

- Flush lines before fitting spray valves; debris ruins check disks.

- Measure cabinet swing for knee valves; 50 mm clearance needed behind door.

- Flow calibration: use a pitcher test—should fill 1 gal in 60 s for WaterSense units.

- Spare parts kit: stock washers and O-rings on-site; five-minute repairs avert replacements.

8. Total Cost of Ownership Snapshot

| Tap Type | 5-Year Cost* | Labour Saved | Utility Saved | Net Benefit |

|---|---|---|---|---|

| Pre-rinse | US $520 | 450 hrs | 300 k gal | US $5 480 |

| Gooseneck | US $280 | 120 hrs | 40 k gal | US $1 620 |

| Pot filler | US $810 | 350 hrs | n/a | US $3 890 |

| Knee valve | US $190 | n/a | 90 k gal | US $880 |

| Sensor | US $430 | n/a | 30 k gal | US $570 |

*Purchase, service parts, energy where applicable; labour valued at US $14/hr; water-sewer at US $0.01/gal.

9. Recommendations

- High-volume kitchens: pair a Class 1 pre-rinse with an add-on 12″ swing spout; quickest ROI.

- Space-constrained cafés: opt for compact gooseneck pull-downs—good balance of reach and cost.

- Health-critical zones: specify mechanical knee valves over sensors for reliability.

- CapEx strategy: invest in brass, lead-free, NSF-certified bodies; cheaper zinc units corrode within three years.

- Measure TCO rather than sticker price; water, energy and injury reductions eclipse initial outlay.

10. Conclusion

A faucet may seem inconspicuous, yet it orchestrates sanitation, speed and spend in every commercial kitchen. Operators who align tap technology with workflow typically cut utilities by double digits and free staff for higher-value tasks. Use this evidence-based framework to select hardware that pays for itself and then some.

Key commercial kitchen tap types and their distinctive designs