This technical report provides a comprehensive analysis of the fundamental construction differences between three primary categories of commercial dishwashing equipment. Through direct engineering assessment and practical field experience, this analysis examines the structural design principles, component specifications, and performance characteristics that differentiate utensil washers, commercial pot washers, and undercounter dishwashers.

Executive Summary

The commercial dishwashing industry utilizes three distinct equipment categories, each engineered for specific operational requirements and capacity demands. Utensil washers represent the most robust construction category, designed for heavy-duty processing of large cookware and serving equipment. Commercial pot washers offer specialized design elements optimized for grease-cutting performance and large-volume pot cleaning operations. Undercounter dishwashers prioritize space efficiency and moderate capacity requirements while maintaining commercial-grade performance standards.

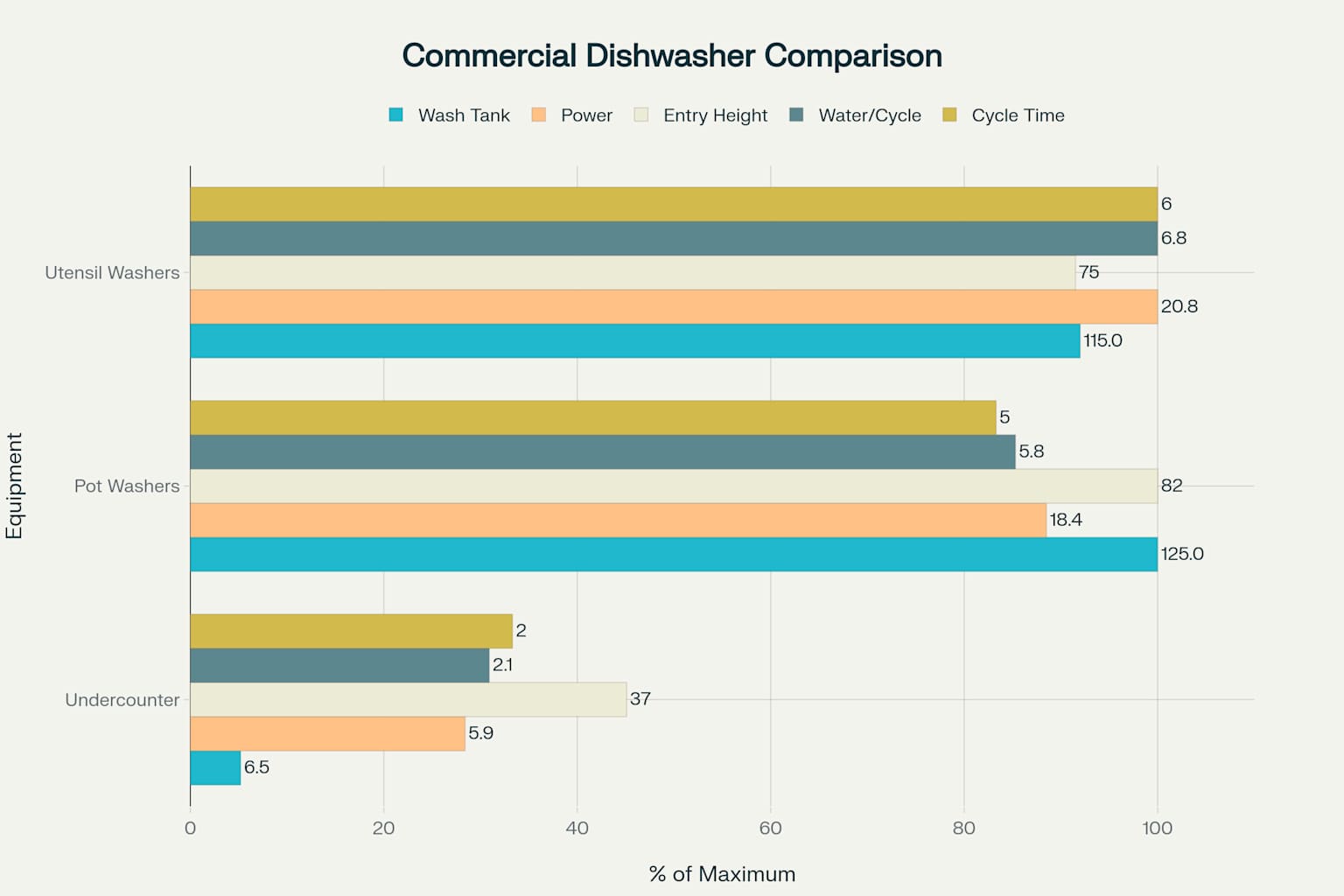

Technical Performance Comparison of Commercial Dishwashing Equipment Types

Construction Analysis by Major Systems

Wash Tank Engineering and Capacity Design

The fundamental construction difference between these equipment types begins with wash tank design and capacity engineering.

Utensil washers employ large capacity molded tanks ranging from 100-130 liters, incorporating reinforced construction specifically engineered to handle heavy items such as hotel pans, large stockpots, and institutional cookware. The tank construction utilizes heavy-gauge stainless steel with reinforced mounting points to withstand the mechanical stresses imposed by large, water-filled containers during wash cycles.

Commercial pot washers utilize robust welded tank construction with capacities of 100-150 liters, optimized specifically for large cookware washing applications. The welded construction methodology provides superior structural integrity compared to molded alternatives, enabling these units to handle the thermal cycling and mechanical stresses associated with continuous pot washing operations.

Undercounter dishwashers employ compact molded tanks with significantly reduced capacity of 5.4-7.5 liters, reflecting their space-efficient design philosophy. This compact construction prioritizes installation flexibility while maintaining adequate washing performance for standard dishware applications.

Pump System Design and Hydraulic Engineering

Pump system design represents a critical differentiator in construction methodology across these equipment categories. Utensil washers incorporate high-flow centrifugal pumps ranging from 2.2-5.0kW with stainless steel impellers specifically designed for debris handling capabilities. The pump construction includes debris-tolerant impeller geometry and reinforced volutes to handle food particles and cooking residues commonly encountered in institutional kitchen operations.

Commercial pot washers utilize variable-speed pump systems with power ranges from 0.6-7.5kW, incorporating debris-tolerant design elements. The variable-speed capability allows optimization of wash pressure for different cookware types while maintaining energy efficiency during lighter soil load conditions.

Undercounter units employ small centrifugal pumps ranging from 0.25-1.0kW, optimized for regular dishware processing. These pumps prioritize quiet operation and energy efficiency over maximum flow capacity, reflecting their installation requirements in customer-facing environments.

Heating System Architecture

The heating system architecture demonstrates significant construction variations based on operational requirements.

Utensil washers employ dual heating element configurations consisting of tank heaters (3-9kW) combined with powerful boilers (9-18kW), providing rapid temperature recovery essential for high-volume operations. This dual-element approach ensures consistent temperature maintenance during continuous loading cycles while providing adequate thermal capacity for sanitizing rinse requirements.

Commercial pot washers incorporate high-capacity heating systems with tank elements ranging 2.1-8kW and boilers up to 25kW. This heating capacity addresses the thermal mass challenges associated with large cookware while ensuring effective grease cutting performance through maintained temperature profiles.

Undercounter dishwashers utilize integrated heating systems with small tank heaters (2-3kW) and compact boilers (2.6-6kW) . The integrated design philosophy prioritizes space efficiency while providing adequate thermal performance for standard dishware sanitation requirements.

Spray Arm Configuration and Water Distribution

Spray arm design and water distribution systems reflect specialized engineering for different soil removal requirements. Utensil washers incorporate reinforced rotating arms with anti-block nozzles designed for high-pressure operation up to 1 bar. The reinforced construction addresses the mechanical stresses imposed by high-flow, high-pressure operation while the anti-block nozzle design prevents food particle obstruction during heavy soil load processing.

Commercial pot washers employ oscillating wash arms with specialized jet patterns optimized for pot and pan cleaning. The oscillating mechanism provides enhanced coverage patterns specifically designed to address the geometric challenges of cleaning large, deep cookware while maintaining effective grease cutting performance.

Undercounter dishwashers utilize standard rotating spray arms with conventional nozzle patterns. The standard configuration prioritizes reliable operation and ease of maintenance while providing adequate cleaning performance for regular dishware applications.

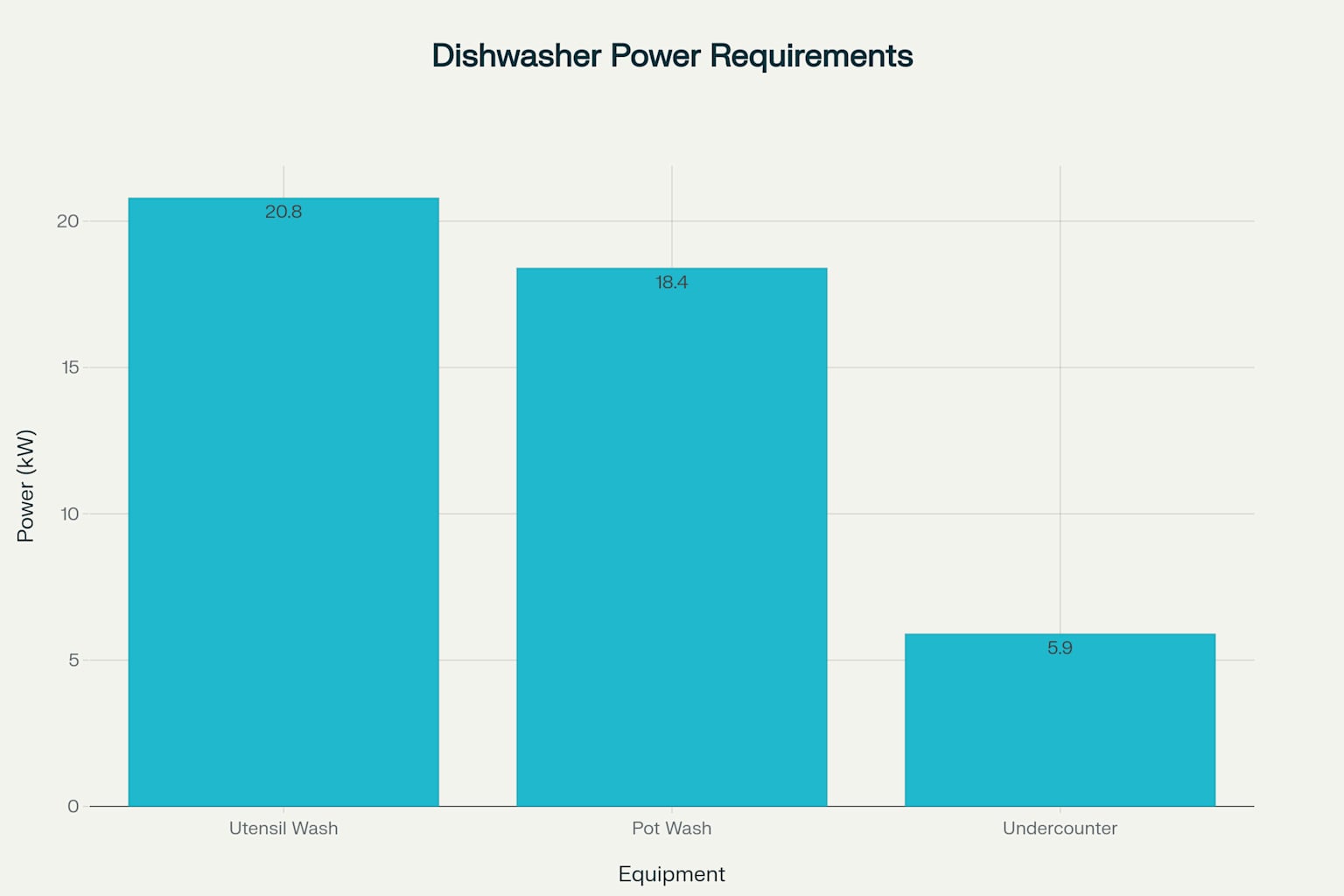

Power Requirements vs Construction Complexity in Commercial Dishwashing Equipment

Technical Performance and Construction Complexity

The relationship between construction complexity and performance requirements demonstrates clear differentiation across equipment categories. Utensil washers exhibit the highest construction complexity with total connected loads ranging 16.7-25.0kW, reflecting their industrial-grade component specifications and multiple subsystem integration. This complexity directly correlates with their capability to process large, heavily soiled items while maintaining NSF sanitization standards.

Commercial pot washers demonstrate variable complexity with connected loads spanning 6.7-30.0kW, reflecting their adaptability to different operational scales. The wide power range accommodation requires sophisticated electrical design and component selection to ensure reliable operation across varying load conditions.

Undercounter dishwashers maintain moderate complexity with connected loads of 2.85-9.0kW, balancing performance requirements with installation simplicity. This controlled complexity enables installation by qualified service technicians without requiring specialized electrical infrastructure modifications.

Filtration System Engineering

Filtration system design reflects the debris handling requirements specific to each equipment category. Utensil washers employ triple-tier filtration systems incorporating coarse pre-filters, fine mesh filters, and dual scrap collection trays. This multi-stage approach addresses the large debris particles and food residues typically encountered in institutional cookware washing while protecting downstream pump components.

Commercial pot washers utilize heavy-duty dual filtration with self-cleaning features and large debris capacity. The self-cleaning capability reduces maintenance requirements while the large debris capacity accommodates the food particles and cooking residues associated with pot and pan washing operations.

Undercounter dishwashers employ basic filtration consisting of removable mesh filters with simple debris collection. This simplified approach prioritizes ease of maintenance while providing adequate filtration for the smaller debris particles typically encountered in standard dishware processing.

Regulatory Compliance and Standards Integration

All three equipment categories must comply with NSF/ANSI Standard 3 requirements, though with different performance classifications.

Utensil washers fall under the High Volume Category, requiring enhanced temperature monitoring and sanitization verification systems. The regulatory compliance necessitates digital temperature sensors with data logging capability and comprehensive documentation systems.

Commercial pot washers operate under the Heavy Duty Category with specific requirements for surface temperature verification and infrared monitoring capabilities. The regulatory framework requires professional installation with utility upgrades and comprehensive maintenance scheduling.

Undercounter dishwashers comply with Light Duty Category standards, allowing simplified temperature monitoring and basic safety systems. The reduced regulatory complexity enables installation by qualified service technicians with standard electrical connections.

Engineering Recommendations

Based on extensive field experience and technical analysis, the selection of appropriate equipment type should prioritize operational requirements over initial cost considerations. Utensil washers provide optimal performance for high-volume institutional operations requiring processing of large cookware and serving equipment. Their robust construction justifies the higher initial investment through extended service life and consistent performance under demanding conditions.

Commercial pot washers offer specialized performance advantages for operations with significant pot and pan washing requirements, particularly in bakery and production kitchen environments. The grease-cutting capability and large item accommodation justify their selection for specific operational profiles.

Undercounter dishwashers provide cost-effective solutions for moderate-volume operations with space constraints, offering commercial-grade performance in compact configurations. Their simplified maintenance requirements and standard utility connections enable efficient operation in smaller commercial establishments.

Conclusion

The construction differences between utensil washers, commercial pot washers, and undercounter dishwashers reflect fundamental engineering approaches to different operational requirements. Utensil washers prioritize maximum durability and capacity through robust construction and high-power components. Commercial pot washers balance specialized performance with operational flexibility through variable-capacity systems and enhanced cleaning mechanisms. Undercounter dishwashers optimize space efficiency and installation simplicity while maintaining commercial performance standards.

These construction differences directly impact operational performance, maintenance requirements, and total cost of ownership. Proper equipment selection based on construction characteristics and operational requirements ensures optimal performance and long-term reliability in commercial kitchen operations. The engineering analysis demonstrates that construction complexity correlates directly with operational capability, validating the importance of proper equipment specification in commercial warewashing system design.