Installing a commercial dishwasher requires meticulous planning, adherence to multiple codes, and professional expertise across electrical, plumbing, and ventilation systems. This comprehensive guide provides restaurant owners, facility managers, and installation professionals with the essential knowledge needed for successful commercial dishwasher installation, covering everything from initial site preparation to final commissioning and code compliance.

Pre-Installation Planning and Site Assessment

Space Requirements and Infrastructure Evaluation

Proper commercial dishwasher installation begins with thorough site assessment and infrastructure evaluation. The installation area must provide adequate clearance for the dishwasher unit, typically requiring six inches of clearance on all sides for proper ventilation and service access. Commercial dishwasher professional installation requirements mandate that ceiling height must accommodate exhaust hood installation, with minimum clearances of 24 inches above the unit for Type II ventilation hoods.

Site preparation involves verifying the structural integrity of the floor to support the weight of the dishwasher when fully loaded with water, which can exceed 500 pounds for larger conveyor-type units. The installation location should facilitate efficient workflow between dirty dish collection, washing operations, and clean dish storage areas to optimize kitchen productivity.

Utility Infrastructure Assessment

Before proceeding with installation, verify that all utility connections meet commercial dishwasher specifications. Electrical service must provide adequate capacity for the unit’s power requirements, with most commercial dishwashers requiring 208-240V service at 15-30 amperes for single-phase units or 20 amperes per phase for three-phase installations. Water supply infrastructure must deliver consistent pressure between 2-4 bar (29-58 PSI) with flow rates of 2-4 GPM minimum to ensure proper operation.

Electrical Requirements and Power Specifications

Voltage and Circuit Requirements

Commercial dishwasher electrical requirements vary significantly based on unit type and capacity. Under-counter models typically operate on single-phase 208-240V power, while larger conveyor systems require three-phase electrical service for optimal performance. High-temperature commercial dishwasher electrical specifications include booster heater requirements that can add 10-15 kW to the total electrical load, necessitating dedicated circuit protection and proper conductor sizing.

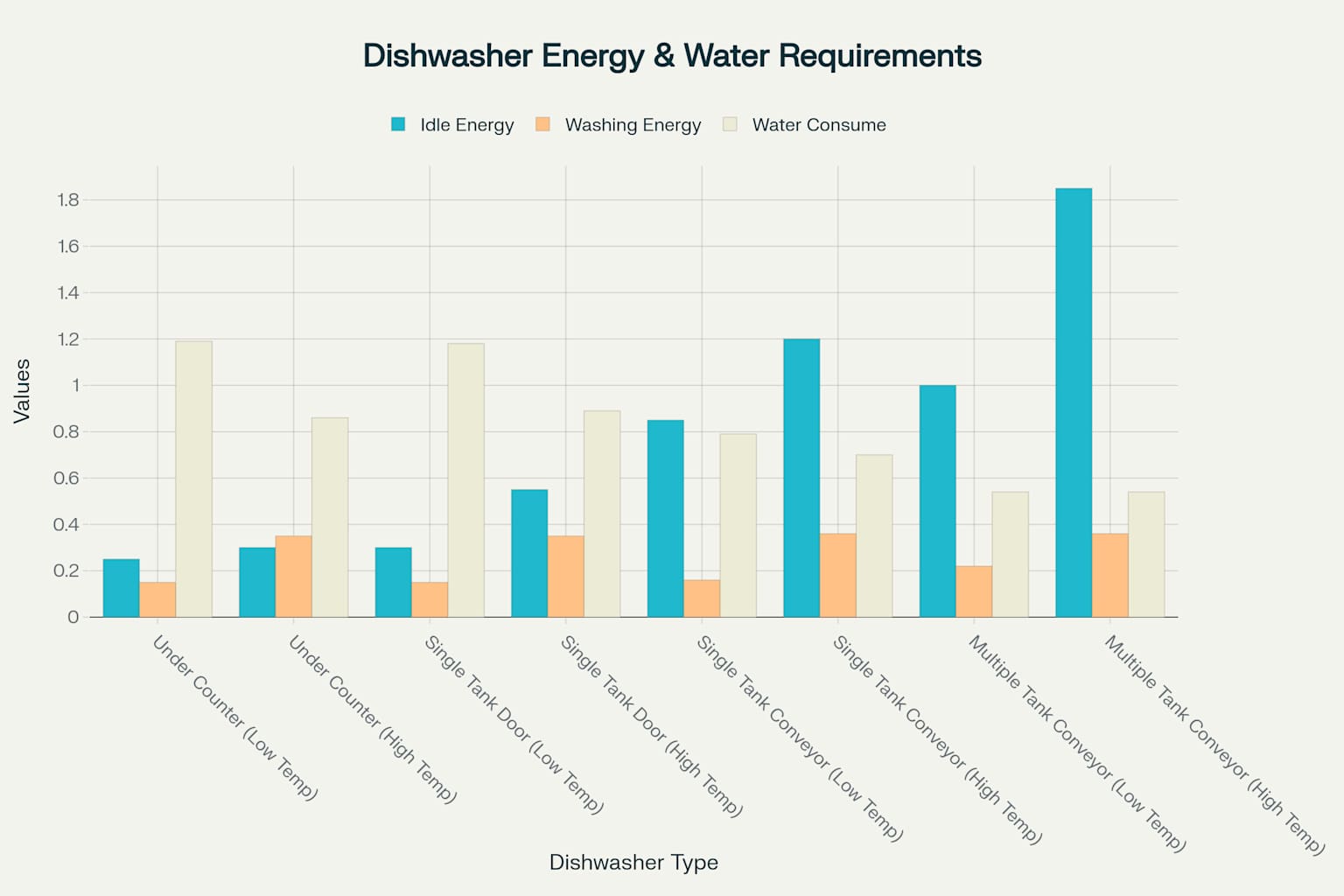

Energy Star Efficiency Requirements for Commercial Dishwashers by Type

The electrical installation must comply with National Electrical Code (NEC) standards, requiring hard-wired connections through appropriate junction boxes with proper strain relief. GFCI protection is mandatory for all commercial dishwasher installations, providing enhanced safety protection against electrical faults in the wet environment of commercial kitchens.

Professional Electrical Installation Standards

Licensed electricians must handle all electrical connections to ensure code compliance and warranty protection. The electrical installation includes proper grounding connections, emergency disconnect switches within sight of the unit, and circuit breaker sizing based on the manufacturer’s specifications. 208V three-phase commercial dishwasher installation guide requirements specify that electrical connections must be accessible for future maintenance while remaining protected from moisture and mechanical damage.

Plumbing and Water Supply Systems

Water Supply Connection Requirements

Commercial dishwasher water supply systems require careful attention to pressure, temperature, and flow rate specifications. The incoming hot water supply must maintain 140°F (60°C) temperature with sufficient flow capacity to meet the dishwasher’s cycle requirements. Water pressure regulation is critical, with pressure reducers required when supply pressure exceeds 4 bar and booster pumps necessary when pressure falls below 2 bar minimum.

The water supply line connection utilizes standard 3/4-inch fittings with shutoff valves positioned within three feet of the dishwasher for emergency isolation. Water hammer arrestors must be installed to protect against pressure surges from quick-acting solenoid valves, and all supply line materials must comply with NSF 61 standards for potable water contact.

Advanced Water Quality Considerations

Restaurant dishwasher ventilation system CFM requirements work in conjunction with water supply quality to ensure optimal performance. Hard water conditions may require water softening equipment to prevent mineral buildup in heating elements and spray arms. Energy Star commercial dishwasher water consumption standards mandate efficient water usage, with high-efficiency models consuming less than 1.0 gallons per rack for certain dishwasher types.

Drainage Systems and Backflow Prevention

Commercial Dishwasher Drain Code Compliance

Commercial dishwasher drain system air gap requirements mandate direct connection to the drainage system with proper protection against backflow contamination. The drainage system must handle discharge volumes of 25+ gallons per cycle, requiring minimum 2-inch diameter drain pipes with proper slope toward the building’s main drain system. Floor drains must be positioned adjacent to the dishwasher to capture any overflow or operational spillage.

Commercial kitchen dishwasher backflow prevention installation requires either air gap separation or approved backflow prevention devices to protect the potable water supply from contamination. The backflow preventer must be tested annually by certified technicians to ensure continued protection and regulatory compliance.

Waste Water Management Systems

Drain hose installation requires proper securing with stainless steel clamps to handle high-temperature discharge water from final rinse cycles. The drainage system design must accommodate thermal expansion and contraction while maintaining leak-proof connections throughout the dishwasher’s operational life. Grease interceptor systems must be bypassed for dishwasher connections, as these units are specifically excluded from grease waste treatment requirements.

Ventilation and Exhaust System Design

Exhaust Hood Requirements and Sizing

Commercial dishwasher exhaust hood installation requires Type II hoods specifically designed for steam and heat removal rather than grease capture. The exhaust hood must extend minimum six inches beyond the dishwasher on all sides to ensure complete capture of steam and heat generated during wash and rinse cycles. Hood construction utilizes stainless steel with removable baffle systems for easy cleaning and maintenance access.

Commercial dishwasher installation technical diagram showing all required components

Ventilation system sizing follows established guidelines requiring 300-1000 CFM exhaust capacity based on dishwasher size and heat output. The minimum ventilation rate calculation uses 100 CFM per linear foot of hood length, with additional capacity required for high-temperature rinse systems that generate substantial steam volumes.

Ductwork and Air Distribution

NSF certified commercial dishwasher installation standards require galvanized steel ductwork with proper insulation to prevent condensation formation. The ductwork must be sloped toward the exhaust fan to prevent grease and moisture accumulation that could create fire hazards or system failures. Ductwork termination must direct exhaust away from building openings, air intakes, and property lines in accordance with local building codes.

Make-up air systems must be sized to prevent excessive negative pressure in the kitchen area, with regulations limiting negative pressure to 0.02 inches water column maximum. Properly balanced ventilation systems improve energy efficiency while maintaining safe working conditions for kitchen staff.

Technical Specifications and Performance Standards

Energy Efficiency and Consumption Standards

IMC ventilation code compliance commercial dishwashers must meet stringent energy and water efficiency standards. Under-counter low-temperature units must maintain idle energy consumption below 0.25 kW, while high-temperature models allow up to 0.30 kW idle energy rate. Single tank conveyor systems have higher energy allowances, with low-temperature models limited to 0.85 kW and high-temperature units up to 1.20 kW idle energy consumption.

Water consumption standards vary by dishwasher type, with under-counter models limited to 1.19 gallons per rack for low-temperature operation and 0.86 gallons per rack for high-temperature systems. Multiple tank conveyor dishwashers achieve the highest efficiency at 0.54 gallons per rack for both temperature ranges, reflecting their optimized design for high-volume operations.

Temperature and Sanitization Requirements

High-temperature dishwashers must maintain final rinse temperatures between 180-195°F to achieve proper sanitization without chemical additives. Low-temperature chemical sanitization systems require precise chemical injection rates and contact times to ensure effective pathogen elimination. Temperature monitoring systems with digital displays and alarms provide operators with real-time feedback on system performance and compliance with health department regulations.

Commercial dishwasher booster heater electrical requirements add significant electrical load, typically requiring 10-15 kW capacity for high-temperature rinse systems. Booster heaters must be properly sized to maintain temperature throughout peak operation periods while minimizing energy consumption during idle periods.

Code Compliance and Inspection Requirements

Required Certifications and Standards

Equipment certification through NSF/ANSI 3-2019 standards ensures commercial dishwashers meet safety, sanitation, and performance requirements. Installation must comply with International Mechanical Code (IMC) provisions for ventilation systems, local plumbing codes for water supply and drainage connections, and electrical codes for power distribution and safety systems.

Health department approval requires documentation of proper installation, testing results, and operator training completion. The approval process typically includes inspection of water temperature capabilities, chemical sanitization systems, and ventilation performance measurements to verify compliance with local health regulations.

Professional Inspection Process

Rough electrical and plumbing inspections occur before concealing any connections within walls or floor systems. These inspections verify proper conductor sizing, junction box installation, water supply line routing, and drainage system connections. Final inspections include performance testing of all systems to ensure proper operation and code compliance.

Ventilation system commissioning requires airflow measurements to verify exhaust rates meet design specifications and makeup air systems maintain proper pressure relationships. Documentation of test results becomes part of the permanent facility records for future reference and regulatory compliance verification.

Installation Best Practices and Professional Recommendations

Project Management and Coordination

Successful commercial dishwasher installation requires coordination between multiple trades including electrical, plumbing, and HVAC contractors. Project scheduling must sequence rough-in work before finish construction while allowing adequate time for inspections and corrections. Equipment delivery timing should align with installation readiness to minimize storage requirements and potential damage.

Quality control measures include verification of all utility connections before equipment energization, testing of safety systems including emergency shutoffs and door interlocks, and performance verification under actual operating conditions. Professional installation teams maintain detailed documentation of all work performed, providing facility owners with comprehensive records for warranty and maintenance purposes.

Long-term Maintenance Planning

Proper installation establishes the foundation for reliable long-term operation and reduced maintenance costs. Accessibility for future service work must be maintained, with adequate clearance for component removal and replacement. Service documentation including electrical diagrams, plumbing schematics, and ventilation specifications should be provided to facility maintenance staff along with recommended maintenance schedules and supplier contact information.

Training programs for operational staff ensure proper use of equipment controls, understanding of safety procedures, and recognition of potential problems requiring professional attention. Well-trained operators extend equipment life while maintaining optimal performance and regulatory compliance throughout the dishwasher’s service life.

This comprehensive installation guide provides the essential knowledge required for professional commercial dishwasher installation, ensuring compliance with all applicable codes while optimizing performance and reliability for years of successful operation.