Commercial dishwashers are the backbone of any food service operation, processing hundreds of cycles daily in restaurants, hotels, and institutional kitchens. When these critical machines malfunction, operations can grind to a halt, leading to significant revenue loss and health code violations. This comprehensive troubleshooting guide provides practical, experience-based solutions for the most common commercial dishwasher problems, helping kitchen managers and maintenance staff quickly diagnose and resolve issues.

Problem 1: Commercial Dishwasher Not Draining Properly

Poor drainage is the most frequently reported issue in commercial dishwashers, accounting for approximately 35% of service calls. This problem typically manifests as standing water in the bottom of the unit after a complete cycle, creating unsanitary conditions and preventing proper operation.

Primary Causes and Solutions

Clogged Filter System: The drain filter captures food debris and prevents it from entering the drain system. In high-volume operations, these filters can become completely blocked within hours if not properly maintained.

Solution Steps:

- Turn off power and allow the unit to cool completely

- Remove the bottom dish rack to access the filter assembly

- Lift out the cylindrical filter cage and rinse under hot water

- Use a soft brush to remove stubborn debris from filter holes

- Inspect the sump area for accumulated grease and clean thoroughly

Blocked Drain Hose: Food particles, grease buildup, and external blockages in the facility’s drain system can prevent proper water evacuation.

Solution Steps:

- Disconnect the drain hose from the garbage disposal or sink drain

- Use a drain snake or high-pressure water to clear blockages

- Check that the hose isn’t kinked or compressed behind the unit

- Ensure proper hose elevation to prevent backflow

Faulty Drain Pump: When mechanical components fail, the pump cannot generate sufficient pressure to evacuate water effectively.

Diagnostic Steps:

- Listen for unusual noises during the drain cycle

- Check pump impeller for damage or debris

- Test pump motor electrical continuity with a multimeter

- Professional replacement required if motor failure is confirmed

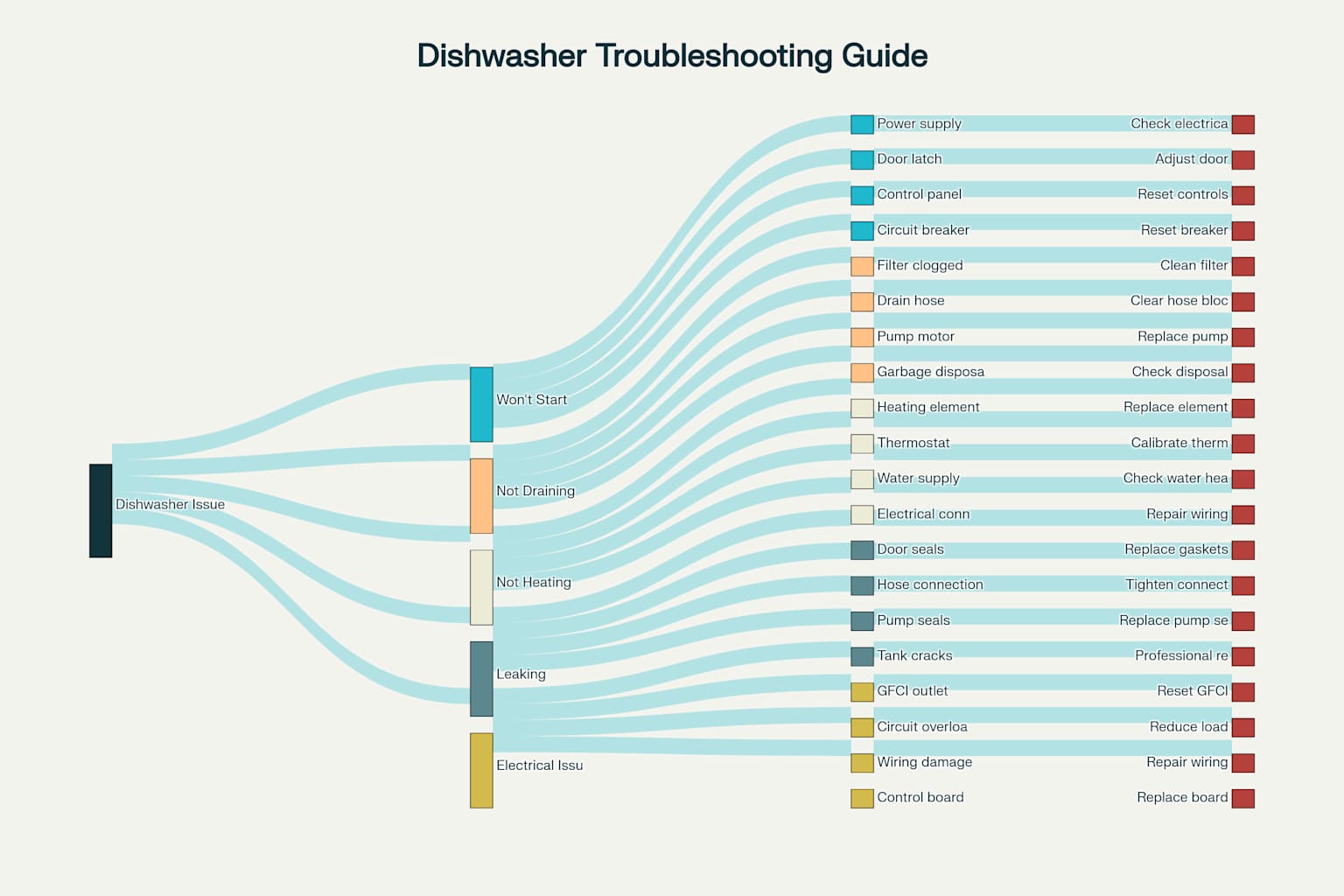

Commercial Dishwasher Troubleshooting Flowchart – Quick Diagnostic Guide

Problem 2: Commercial Dishwasher Not Heating Water

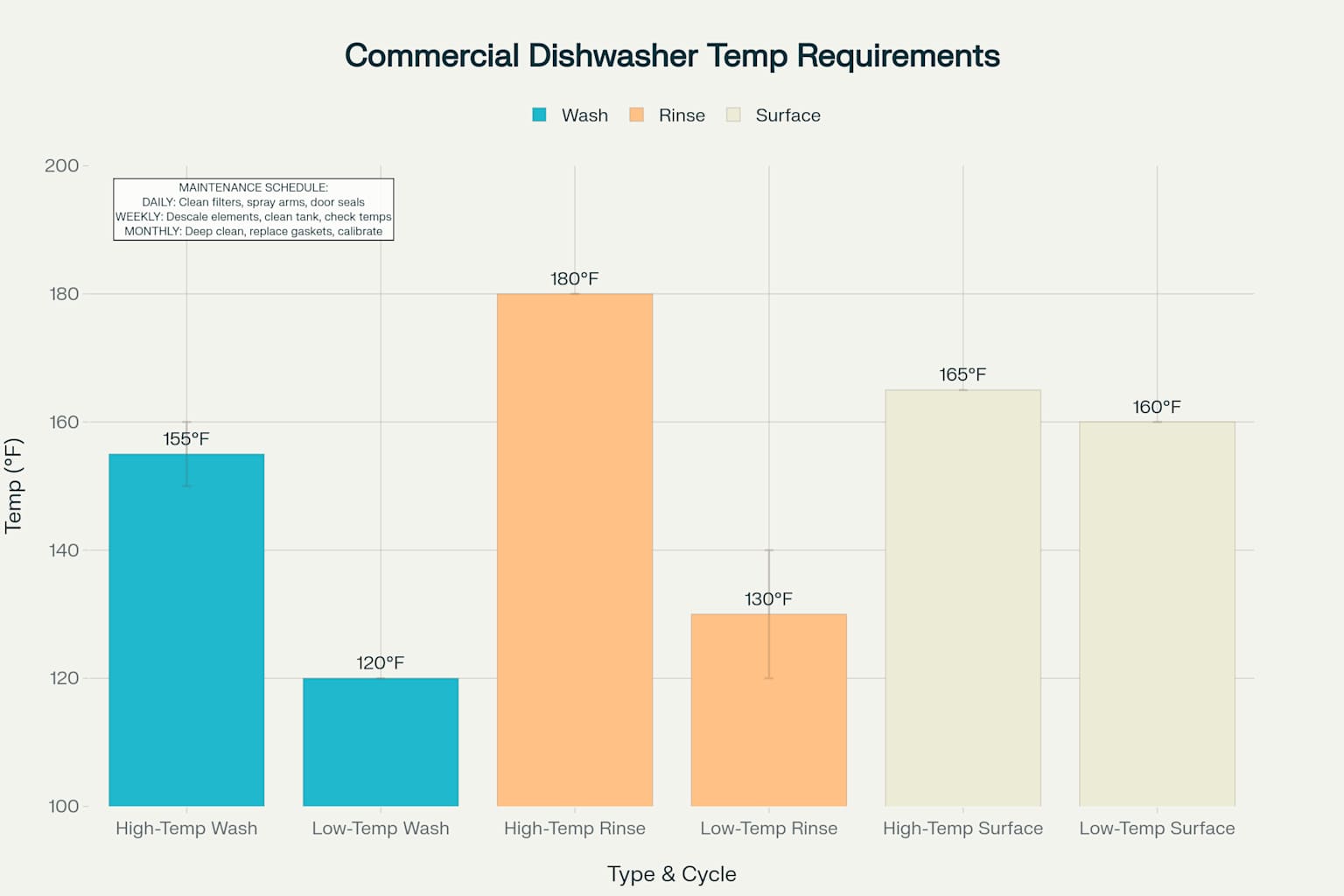

Temperature-related failures represent critical food safety violations, as proper sanitization requires specific water temperatures mandated by health departments. High-temperature dishwashers must achieve 180°F (82°C) final rinse temperatures, while low-temperature units require 120-140°F (49-60°C) wash temperatures.

Heating Element Diagnosis and Replacement

Testing Heating Element Continuity: A faulty heating element is the primary cause of temperature issues in 60% of cases.

Professional Testing Procedure:

- Disconnect power and remove lower access panel

- Locate heating element terminals at the bottom of the unit

- Use a digital multimeter to test resistance between terminals

- Normal resistance should read 10-20 ohms; infinite resistance indicates failure

- Visual inspection should reveal no cracks, corrosion, or burn marks

Heating Element Replacement Process: This procedure requires electrical expertise and should only be performed by qualified technicians.

Replacement Steps:

- Drain the dishwasher completely and disconnect power

- Remove the dishwasher from its installation position

- Access heating element mounting nuts from underneath the unit

- Disconnect electrical wires and mark their positions

- Remove old element and install new element with proper gaskets

- Reconnect wiring and test for proper operation

Thermostat Calibration Issues: Temperature sensors and thermostats can drift over time, causing inaccurate temperature control.

Calibration Verification:

- Use a calibrated digital thermometer to verify actual water temperature

- Compare readings with the dishwasher’s internal temperature display

- Adjust thermostat settings according to manufacturer specifications

- Document temperature readings for health department compliance

Commercial Dishwasher Temperature Requirements and Maintenance Schedule Reference Guide

Problem 3: Commercial Dishwasher Electrical Issues and Circuit Breaker Tripping

Electrical problems pose serious safety risks and often indicate underlying component failures that require immediate attention. When commercial dishwashers trip circuit breakers repeatedly, the issue typically involves overloaded circuits, ground faults, or component short circuits.

GFCI Protection and Electrical Safety

Understanding GFCI Requirements: The 2023 National Electrical Code mandates GFCI protection for all commercial dishwashers to prevent electrical shock hazards.

GFCI Troubleshooting Steps:

- Locate the GFCI outlet or breaker serving the dishwasher

- Press the “Test” button to ensure the GFCI is functioning properly

- Reset the GFCI by pressing the “Reset” button firmly

- If the GFCI trips immediately upon reset, a ground fault exists in the circuit

Circuit Overload Analysis: Commercial dishwashers draw significant electrical current, especially during heating cycles.

Load Assessment Procedure:

- Calculate total amperage draw of all appliances on the circuit

- Verify that the dishwasher has a dedicated 20-amp or 30-amp circuit

- Check for loose connections at the electrical panel

- Use a clamp meter to measure actual current draw during operation

Component-Specific Electrical Failures

Heating Element Short Circuits: Failed heating elements often cause immediate breaker trips due to ground faults.

Diagnostic Process:

- Test heating element insulation resistance to ground

- Normal reading should exceed 1 megohm resistance

- Replace element if insulation resistance is compromised

Control Board Malfunctions: Electronic control boards can develop internal short circuits that cause erratic operation.

Control Board Testing:

- Inspect control board for visible burn marks or damaged components

- Test individual relay outputs for proper operation

- Professional replacement required for complex electronic failures

Commercial dishwasher safety maintenance procedures in professional kitchen

Problem 4: Commercial Dishwasher Water Leakage

Water leakage creates safety hazards, damages flooring, and indicates component wear that can lead to complete system failure. Identifying leak sources requires systematic inspection of all water-containing components.

Door Seal and Gasket Replacement

Door Seal Inspection: Door gaskets create the watertight seal necessary for proper operation and are subject to constant wear from thermal cycling and chemical exposure.

Inspection Criteria:

- Check for visible cracks, tears, or hardening of the rubber material

- Test seal compression by closing the door and checking for light gaps

- Inspect mounting groove for accumulated debris or damage

- Replace seals showing any signs of deterioration

Installation Procedure for New Seals:

- Remove old gasket by carefully pulling it from the mounting groove

- Clean the mounting surface thoroughly with degreasing solution

- Apply thin layer of food-grade lubricant to the mounting groove

- Install new gasket ensuring proper alignment and complete seating

Internal Component Leakage

Pump Seal Failures: Internal pump seals can develop leaks that allow water to escape from the wash chamber.

Pump Seal Diagnosis:

- Remove lower access panel to inspect pump housing

- Look for water stains or mineral deposits around pump connections

- Professional pump rebuild or replacement required for seal failures

Tank and Plumbing Connections: Loose fittings and worn connections frequently cause leakage in high-use environments.

Connection Inspection:

- Examine all visible water connections for signs of leakage

- Tighten loose fittings using appropriate tools

- Replace corroded or damaged fittings promptly

Safety Procedures and Professional Standards

Commercial dishwasher repair requires strict adherence to safety protocols to prevent injury and ensure compliance with occupational safety standards. The high temperatures, electrical hazards, and chemical exposure present in commercial dishwashing environments demand comprehensive safety measures.

Essential Safety Equipment and Procedures

Personal Protective Equipment Requirements: All maintenance personnel must use appropriate PPE during commercial dishwasher service.

Required Safety Equipment:

- Heat-resistant gloves rated for temperatures up to 200°F

- Safety glasses with side shields for chemical splash protection

- Non-slip safety shoes with closed toes

- Chemical-resistant aprons for cleaning operations

Electrical Safety Protocols: Electrical work on commercial dishwashers requires specific lockout/tagout procedures.

Electrical Safety Steps:

- Turn off power at the main electrical panel

- Test electrical circuits with a non-contact voltage tester

- Apply lockout devices to prevent accidental energization

- Verify zero energy state before beginning work

Temperature and Chemical Safety

Hot Water Safety Measures: Commercial dishwashers operate at extremely high temperatures that can cause severe burns.

Temperature Safety Protocols:

- Allow dishwasher to cool completely before internal access

- Use calibrated thermometers to verify safe working temperatures

- Post temperature warnings in maintenance areas

- Provide immediate access to cold water for emergency cooling

Chemical Handling Procedures: Commercial dishwashing chemicals are highly concentrated and require careful handling.

Chemical Safety Requirements:

- Maintain current Safety Data Sheets for all chemicals used

- Provide adequate ventilation during chemical handling

- Install emergency eyewash stations within immediate access

- Train all personnel in proper chemical mixing procedures

Preventive Maintenance Program Implementation

A structured preventive maintenance program can reduce commercial dishwasher breakdowns by up to 75% while extending equipment lifespan significantly. Professional maintenance schedules address both performance optimization and regulatory compliance requirements.

Daily Maintenance Requirements

End-of-Shift Cleaning Procedures: Proper daily maintenance prevents most common dishwasher problems and ensures optimal performance.

Critical Daily Tasks:

- Remove and clean all filters using hot water and approved detergent

- Clean spray arms by removing food debris from all holes

- Wipe down all external surfaces with sanitizing solution

- Check and refill chemical dispensers to proper levels

- Verify proper door seal operation and cleanliness

Temperature Monitoring and Documentation: Health departments require continuous temperature monitoring to verify sanitization effectiveness.

Temperature Recording Requirements:

- Record wash cycle temperatures at the beginning of each shift

- Verify final rinse temperatures meet NSF/ANSI standards

- Document any temperature deviations and corrective actions taken

- Maintain temperature logs for health department inspections

Weekly and Monthly Service Tasks

Deep Cleaning and Descaling: Weekly descaling prevents mineral buildup that reduces heating efficiency and blocks water flow.

Descaling Procedure:

- Use only manufacturer-approved descaling chemicals

- Follow dilution ratios specified in equipment manuals

- Run complete descaling cycle according to equipment specifications

- Rinse thoroughly to remove all chemical residues

Component Inspection and Testing: Monthly inspections identify potential failures before they cause operational disruptions.

Monthly Inspection Checklist:

- Test heating element resistance and visual condition

- Inspect all electrical connections for corrosion or looseness

- Check pump operation and impeller condition

- Verify proper operation of all safety systems

When to Call Professional Service vs. DIY Repairs

Understanding the limitations of in-house maintenance capabilities prevents safety hazards and ensures warranty compliance. While routine maintenance can be performed by trained staff, complex repairs require professional expertise and specialized tools.

DIY-Appropriate Repairs

Basic Maintenance Tasks: Kitchen staff can safely perform routine maintenance with proper training.

Safe DIY Procedures:

- Filter cleaning and replacement

- Spray arm cleaning and minor adjustments

- Door seal cleaning and minor lubrication

- Basic control panel cleaning and reset procedures

Professional Service Requirements

Electrical and Heating System Repairs: Any work involving electrical components or heating elements requires professional service.

Professional Service Situations:

- Heating element replacement or electrical troubleshooting

- Control board diagnosis and replacement

- Pump motor replacement or rebuilding

- Major component warranty repairs

Gas-Powered Equipment: Commercial dishwashers using gas heating systems require specialized service technicians.

Gas System Safety Requirements:

- Only licensed gas technicians should service gas components

- Proper ventilation and gas leak detection required

- Compliance with local gas utility regulations mandatory

Regulatory Compliance and Health Department Standards

Commercial dishwashers must meet specific performance standards mandated by health departments and industry organizations. Understanding these requirements ensures continued operation and prevents costly violations during inspections.

NSF/ANSI Standards Compliance

Temperature Requirements: NSF/ANSI Standard 3 establishes minimum performance criteria for commercial dishwashers.

Required Performance Standards:

- High-temperature dishwashers: 180°F final rinse temperature

- Low-temperature dishwashers: proper chemical sanitization concentration

- 99.999% bacterial reduction (5-log reduction) for all cycles

- Surface temperature verification using irreversible temperature indicators

HACCP Integration: Hazard Analysis and Critical Control Points programs require documented dishwasher performance monitoring.

HACCP Documentation Requirements:

- Continuous temperature monitoring and recording

- Chemical concentration verification procedures

- Equipment calibration and maintenance records

- Corrective action documentation for any deviations

Energy Efficiency and Environmental Considerations

ENERGY STAR Compliance: ENERGY STAR qualified commercial dishwashers provide significant operational cost savings.

Energy Efficiency Features:

- Optimized wash cycle programming for reduced energy consumption

- Heat recovery systems for improved thermal efficiency

- Advanced water filtration systems for extended wash water use

- Variable speed pump motors for demand-based operation

Conclusion

Effective commercial dishwasher troubleshooting requires a systematic approach combining technical knowledge, safety awareness, and regulatory compliance understanding. The problems addressed in this guide—drainage issues, heating failures, electrical malfunctions, and water leakage—represent the majority of service calls in commercial foodservice operations.

Regular preventive maintenance, proper staff training, and prompt professional service when needed can maintain optimal dishwasher performance while ensuring food safety compliance. Kitchen managers who implement comprehensive maintenance programs report significant reductions in equipment downtime and repair costs.

For complex repairs involving electrical components, heating systems, or gas-powered equipment, always consult qualified service technicians to ensure safety and warranty compliance. The investment in professional service prevents costly equipment damage and maintains the reliable operation essential for successful foodservice operations.

Remember that commercial dishwasher performance directly impacts food safety, operational efficiency, and customer satisfaction. By following the troubleshooting procedures and maintenance guidelines outlined in this guide, foodservice operators can maintain optimal equipment performance while meeting all regulatory requirements for safe food handling.