The Seattle restaurant industry faces unprecedented challenges in 2025, with labor costs reaching critical levels following the elimination of the tip credit and minimum wage increases to $20.76 per hour. This comprehensive analysis examines commercial dishwasher solutions that address these market pressures while delivering operational efficiency and long-term value for Seattle foodservice operators.

Executive Summary

Seattle’s foodservice industry is experiencing a fundamental shift driven by escalating labor costs, space constraints, and regulatory compliance requirements. Commercial dishwashers have emerged as essential equipment for addressing these challenges, offering labor reduction capabilities of up to $3,600 monthly while improving operational efficiency. The analysis reveals that strategic dishwasher investments can achieve return on investment periods ranging from 14 to 22 months, depending on restaurant type and operational volume.

Seattle Restaurant Industry Landscape

Current Market Pressures

The Seattle restaurant market operates under unique pressures that directly impact equipment purchasing decisions. The elimination of the total compensation credit has created a 20% increase in labor costs for small businesses, forcing operators to seek automation solutions that reduce staffing requirements.

Labor costs represent the most significant challenge facing Seattle restaurants, with an impact level of 9 out of 10. This severity has elevated commercial dishwashers from convenience items to strategic necessities for maintaining profitability. Restaurant operators consistently report that manual dishwashing operations require 2-3 dedicated staff members during peak periods, representing $4,000-6,000 in monthly labor costs at current wage rates.

Operational Challenges and Solutions

Seattle’s restaurant density and real estate costs create additional constraints that influence dishwasher selection. Space optimization has become critical, with many operators seeking compact solutions that maximize throughput while minimizing footprint requirements.

The minimum wage impact dominates equipment decision-making, with operators prioritizing solutions that directly reduce labor requirements. Energy costs, while significant, rank lower in priority due to the overwhelming magnitude of labor cost increases.

Commercial Dishwasher Market Analysis

Market Segmentation and Applications

The commercial dishwasher market segments into four primary categories, each serving distinct operational requirements and volume capacities. Understanding these segments is crucial for Seattle operators making equipment investments.

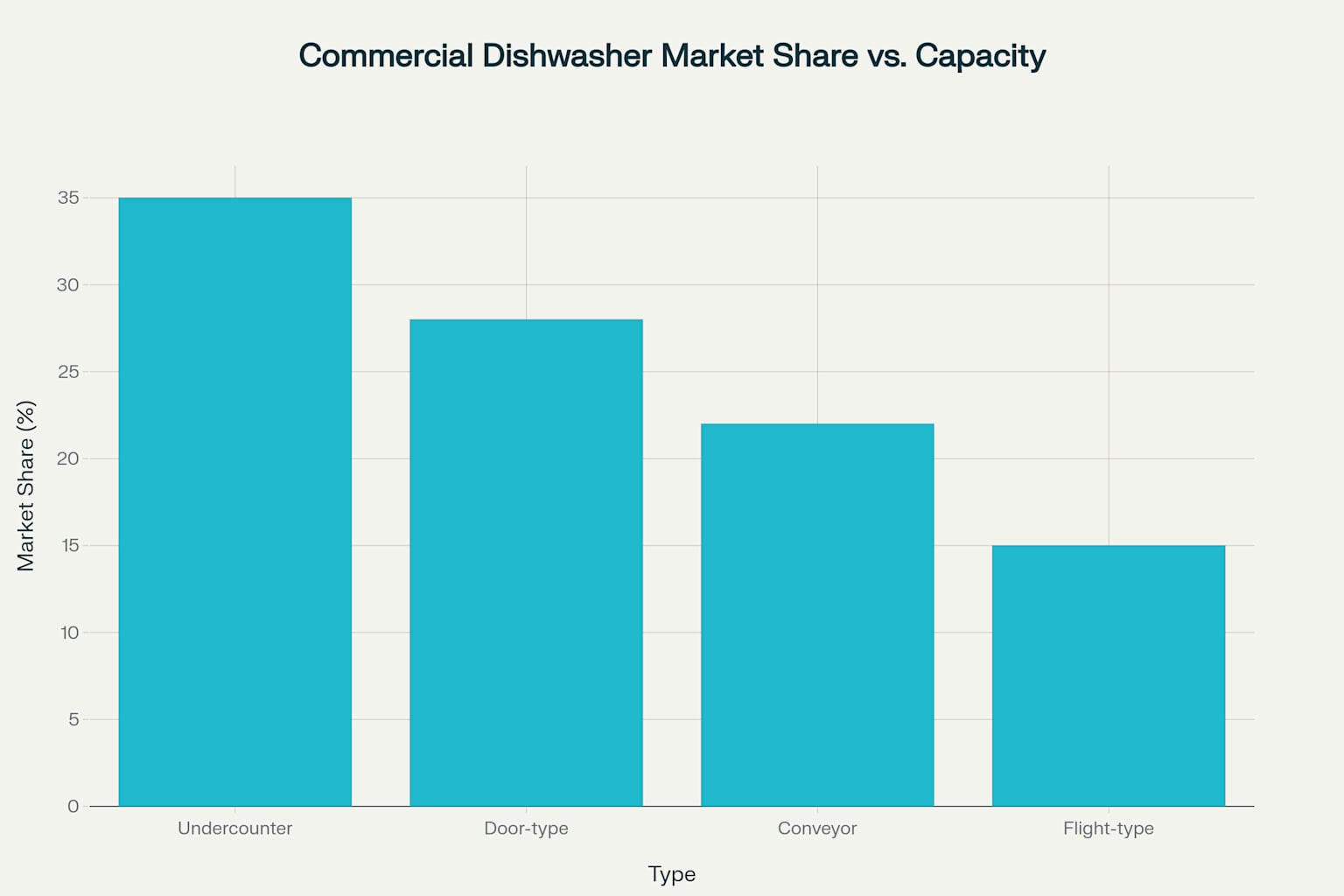

Commercial dishwasher market share compared to processing capacity, showing inverse relationship between market share and capacity

Undercounter dishwashers command the largest market share at 35%, reflecting their suitability for smaller operations and space-constrained environments common in Seattle’s urban core. These units serve fast-casual restaurants, food trucks, and smaller establishments with daily volumes under 200 covers.

Door-type dishwashers represent 28% of the market and serve the backbone of full-service restaurants. With 80 racks-per-hour capacity, these units efficiently handle the demands of mid-sized establishments serving 150-250 covers daily.

Conveyor and flight-type systems serve high-volume operations but represent smaller market shares due to their specialized applications and significant capital requirements.

Total Cost of Ownership Analysis

Understanding the complete financial impact of dishwasher investments requires analysis beyond initial purchase price. The five-year total cost of ownership reveals significant variations across dishwasher categories.

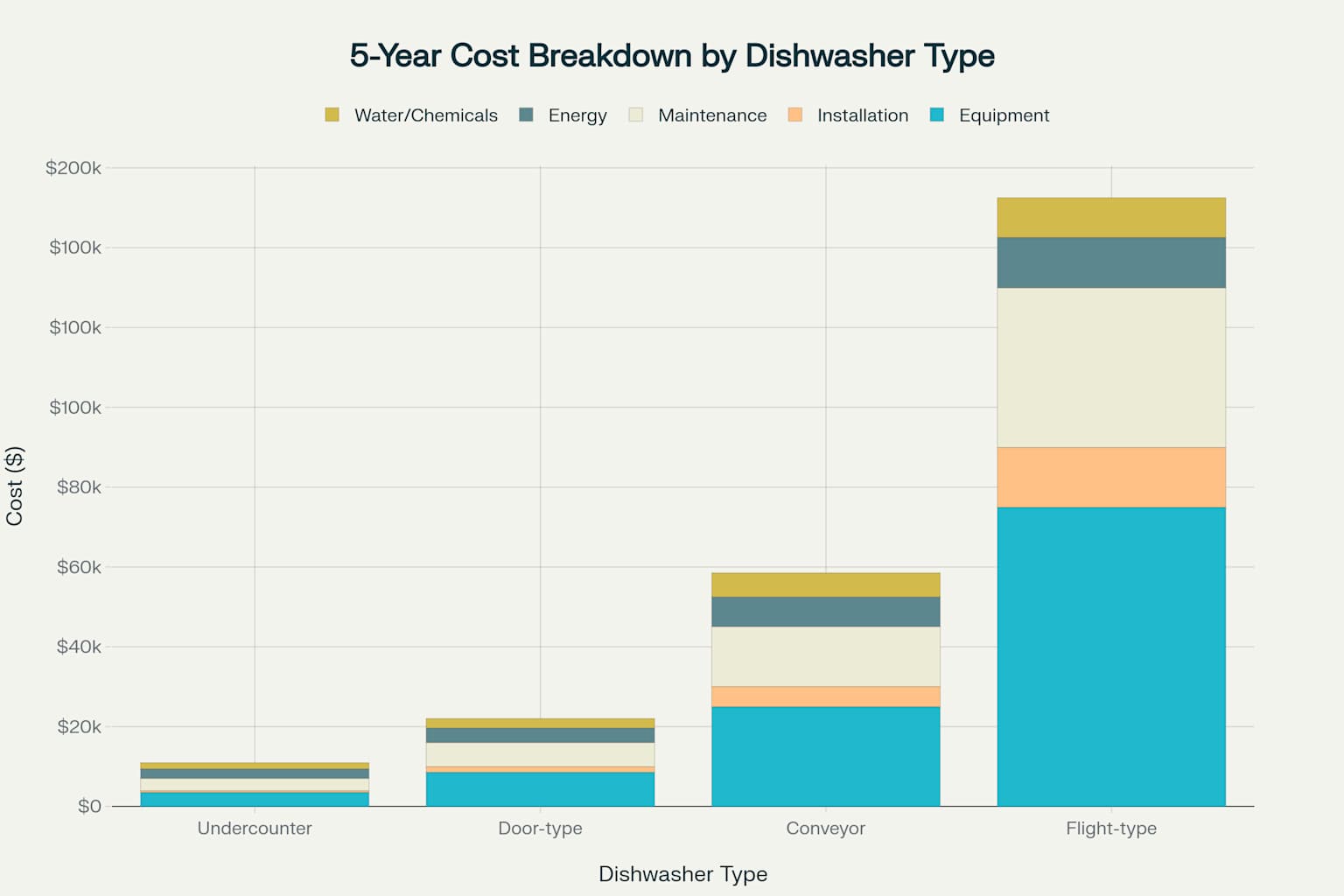

5-Year Total Cost of Ownership comparison for different commercial dishwasher types, showing escalating costs from undercounter to flight-type units

Undercounter units present the lowest entry point at $10,900 over five years, making them accessible for smaller operations and startups. Door-type systems, while requiring double the investment at $22,100, provide substantially higher throughput and labor savings that justify the increased cost for mid-volume operations.

High-capacity conveyor and flight-type systems command premium investments of $58,500 and $152,500 respectively, but serve specialized applications where labor savings and operational efficiency generate rapid payback periods.

Cost Component Breakdown

The financial structure of dishwasher ownership extends beyond purchase price to encompass installation, maintenance, energy, and chemical costs. Understanding these components enables informed decision-making and accurate budgeting.

5-year cost breakdown showing how equipment purchase dominates total costs, with higher-capacity units having proportionally higher operational expenses

Equipment purchase costs dominate the total investment across all categories, representing 60-70% of five-year ownership costs. However, operational expenses including maintenance, energy, and chemicals create ongoing financial obligations that vary significantly by dishwasher type and usage intensity.

Installation costs scale with equipment complexity, ranging from $500 for undercounter units to $15,000 for flight-type systems requiring extensive infrastructure modifications.

Seattle-Specific ROI Analysis

Restaurant Type Recommendations

Seattle’s diverse restaurant landscape requires tailored dishwasher solutions that align with operational volumes, space constraints, and financial resources. Practical experience demonstrates clear patterns in optimal equipment selection.

Fast-casual operations achieving 150 daily covers find optimal value in undercounter systems, generating $800 monthly labor savings with 14-month ROI periods. The compact footprint accommodates typical fast-casual kitchen layouts while providing sufficient capacity for operational demands.

Full-service restaurants serving 200 covers daily require door-type systems to handle increased volume and varied dishware. These installations generate $2,400 monthly labor savings, justifying the higher investment through 18-month payback periods.

Quick-service operations with 300+ daily covers benefit from conveyor systems despite 22-month ROI periods. The $3,600 monthly labor savings and operational efficiency gains prove essential for high-volume operations.

Fine dining establishments, despite lower volumes, often select door-type systems to accommodate specialized glassware and service items requiring careful handling.

Energy Efficiency Considerations

Seattle’s focus on sustainability and rising energy costs emphasizes the importance of energy-efficient dishwasher selection. Operational experience demonstrates measurable differences in energy consumption across efficiency levels.

ENERGY STAR certified units reduce energy consumption by 25% compared to standard models, translating to $360 annual savings. The typical $800 premium cost achieves payback in 2.2 years through energy savings alone, excluding labor and operational benefits.

High-efficiency models offer deeper energy reductions but require 4.2-year payback periods that may not align with shorter equipment replacement cycles common in high-use commercial environments.

Installation and Operational Considerations

Infrastructure Requirements

Successful dishwasher implementation requires careful attention to kitchen infrastructure, utilities, and workflow integration. Seattle’s older building stock often necessitates utility upgrades that impact project costs and timelines.

Electrical requirements vary significantly across dishwasher types, with undercounter units typically requiring standard 208-240V connections while conveyor systems demand 480V three-phase power. Many Seattle restaurants require electrical upgrades costing $2,000-8,000 to support higher-capacity units.

Plumbing modifications represent another infrastructure consideration, particularly for passthrough installations requiring custom fabrication work. Professional installation ensures compliance with Washington State health department requirements while optimizing operational efficiency.

Maintenance and Service Considerations

Commercial dishwasher reliability depends heavily on preventive maintenance programs and access to qualified service technicians. Seattle’s competitive restaurant market demands minimal downtime, making service responsiveness critical.

Maintenance contracts typically cost 8-12% of equipment value annually but provide predictable expenses and priority service response. Given Seattle’s labor shortage affecting all industries, including service technicians, establishing maintenance relationships before equipment failure proves essential.

Water quality variations across Seattle neighborhoods impact dishwasher performance and maintenance requirements. Areas with hard water require more frequent descaling and component replacement, influencing long-term operational costs.

Regulatory Compliance and Food Safety

Washington State Requirements

Commercial dishwashers must comply with Washington State food service regulations, including specific temperature and sanitization requirements. The Washington State Food Service Rules mandate minimum temperatures and chemical concentrations that influence equipment selection.

High-temperature dishwashers achieving 180°F final rinse temperatures provide chemical-free sanitization but require higher energy input. Low-temperature systems using chemical sanitization offer energy efficiency but require ongoing chemical costs and precise monitoring.

Health Department Compliance

Seattle-King County health department inspections evaluate dishwasher installation, operation, and maintenance as critical control points in food safety management systems. Proper documentation and operational procedures prevent violations that could impact restaurant operations.

Dishwasher installation must include adequate ventilation, proper drainage, and NSF-certified equipment to meet health department standards. Professional installation ensures compliance while optimizing operational efficiency.

Strategic Recommendations

Decision Framework

Seattle restaurant operators should evaluate commercial dishwasher investments using a systematic approach that weighs operational volume, space constraints, labor costs, and financial resources.

Establishments serving under 150 daily covers should prioritize undercounter systems that provide immediate labor savings while accommodating space limitations common in Seattle’s urban environment.

Mid-volume operations serving 150-300 covers require door-type systems that balance capacity, efficiency, and investment requirements. These units provide optimal labor savings while maintaining manageable capital requirements.

High-volume operations exceeding 300 covers must consider conveyor systems despite higher investment costs. The labor savings and operational efficiency gains prove essential for maintaining profitability under Seattle’s elevated wage structure.

Implementation Timeline

Successful dishwasher implementation requires 6-12 weeks from specification to operation, depending on infrastructure requirements and equipment availability. Seattle operators should plan installations during slower periods to minimize operational disruption.

Equipment financing options including equipment leasing and SBA loans provide alternatives to cash purchases, preserving working capital while enabling immediate labor savings realization.

Conclusion

Seattle’s restaurant industry faces unprecedented labor cost pressures that make commercial dishwasher investments strategic necessities rather than operational conveniences. The analysis demonstrates clear financial benefits across all restaurant segments, with ROI periods ranging from 14-22 months depending on operational characteristics.

Success requires careful equipment selection aligned with operational volumes, space constraints, and financial resources. Professional installation, preventive maintenance, and energy efficiency considerations optimize long-term value while ensuring regulatory compliance.

The evolving Seattle market demands automation solutions that reduce labor dependency while maintaining operational quality. Commercial dishwashers represent proven technology that addresses these requirements while delivering measurable financial returns and operational improvements.