The dishwasher industry has evolved significantly over the past decades, with stainless steel becoming the predominant material choice for interior components due to its superior corrosion resistance, durability, and hygienic properties. However, not all stainless steel grades perform equally in dishwasher applications. This comprehensive report provides a systematic framework for evaluating dishwasher quality based on stainless steel grade selection, incorporating professional testing methodologies and practical assessment criteria derived from extensive industry experience.

Understanding Stainless Steel Grades in Dishwasher Applications

Material Composition and Properties

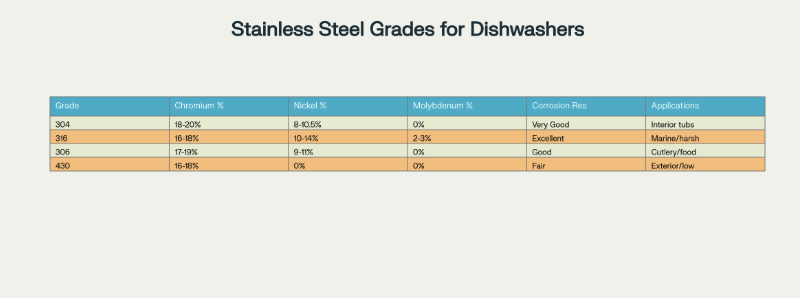

The foundation of dishwasher quality assessment begins with understanding the fundamental differences between stainless steel grades commonly used in appliance manufacturing. Grade 304 stainless steel represents the industry standard, containing 18-20% chromium and 8-10.5% nickel, providing excellent general corrosion resistance and formability. This austenitic grade offers superior heat retention compared to plastic alternatives, contributing to enhanced drying performance through condensation drying systems.

Grade 316 stainless steel incorporates 2-3% molybdenum content, significantly improving resistance to pitting corrosion and chloride attack. This enhanced composition makes it particularly suitable for harsh operating environments or coastal applications where salt exposure is prevalent. The addition of molybdenum creates a more robust passive layer, extending component lifespan in challenging conditions.

Grade 306 stainless steel represents a specialized variant with 17-19% chromium and 9-11% nickel content, designed specifically for food contact applications. This grade exhibits excellent resistance to food acids and cleaning chemicals commonly encountered in dishwasher environments, making it ideal for cutlery contact surfaces and food-adjacent components.

Grade 430 ferritic stainless steel contains 16-18% chromium but no nickel, offering cost-effective corrosion resistance for less demanding applications. While lacking the superior formability of austenitic grades, it provides adequate performance for exterior panels and structural components where direct food contact is not required.

Comparison of Stainless Steel Grades Used in Dishwasher Manufacturing

Performance Characteristics and Applications

From practical experience in dishwasher manufacturing and testing, each stainless steel grade exhibits distinct performance characteristics that directly impact overall appliance quality. Grade 304 demonstrates exceptional balance between performance and cost-effectiveness, making it the preferred choice for interior tubs and door panels. Its superior heat retention properties contribute to energy efficiency by reducing heating element requirements during drying cycles.

Grade 316 excels in extreme conditions, showing measurable improvements in pitting resistance when exposed to chlorinated water supplies or aggressive cleaning formulations. Professional testing reveals that 316 grade components maintain structural integrity and appearance after extended exposure to conditions that would compromise lower-grade materials.

Grade 306 provides specialized performance in food contact applications, demonstrating superior resistance to organic acids and maintaining surface integrity under repeated exposure to food residues. This grade shows particular strength in applications requiring frequent sanitization cycles.

Grade 430 offers economic advantages while maintaining adequate corrosion resistance for non-critical applications. Its magnetic properties facilitate recycling processes, contributing to environmental sustainability considerations.

Professional Quality Assessment Framework

Systematic Evaluation Process

Professional dishwasher quality assessment requires a structured approach that evaluates material selection within the context of overall appliance performance. The assessment process begins with comprehensive material verification, followed by systematic testing of corrosion resistance, performance characteristics, and durability factors.

Initial Assessment Phase involves detailed visual inspection of all stainless steel components, documenting grade specifications, surface finishes, and manufacturing quality indicators. This phase establishes baseline material properties and identifies any obvious defects or inconsistencies in material selection.

Material Analysis Phase employs advanced analytical techniques to verify stainless steel composition and confirm grade specifications. X-ray fluorescence spectroscopy provides rapid elemental analysis, while optical emission spectroscopy offers higher precision for critical alloying elements. This verification ensures that specified grades meet actual performance requirements.

Corrosion Testing Phase evaluates material resistance to environmental factors encountered in typical dishwasher operation. Salt spray testing simulates long-term chloride exposure, while electrochemical testing provides quantitative measurements of corrosion rates under controlled conditions.

Professional Dishwasher Quality Assessment Process Flow

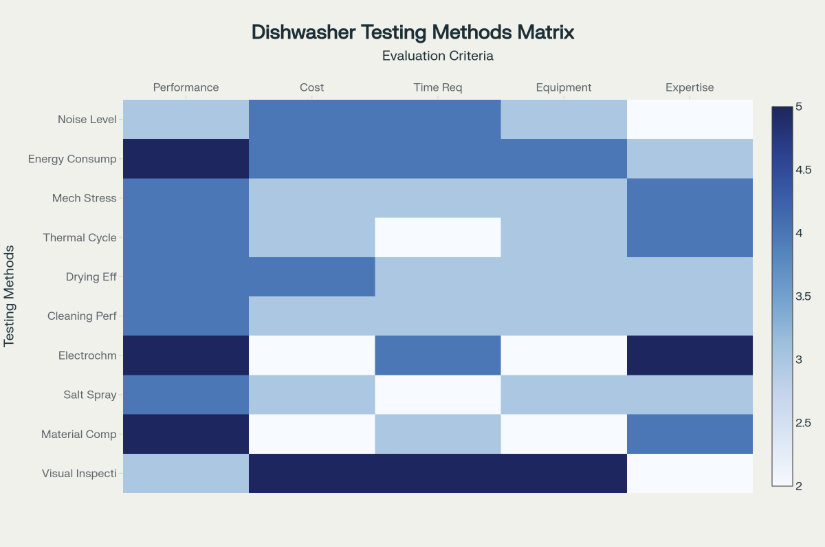

Testing Methodologies and Evaluation Criteria

Corrosion Resistance Testing forms the cornerstone of material quality assessment. Professional salt spray testing following ASTM B117 standards exposes samples to 5% sodium chloride solution at 35°C for extended periods, typically 240-1008 hours depending on grade specifications. Electrochemical impedance spectroscopy provides more sophisticated analysis, measuring passive layer stability and localized corrosion susceptibility.

Performance Testing evaluates how material selection impacts overall appliance functionality. Cleaning performance assessment involves standardized soil removal testing using various food residues under controlled conditions. Drying efficiency testing measures moisture retention on different stainless steel surfaces, with superior grades showing enhanced water drainage and reduced spotting.

Durability Assessment subjects components to mechanical stress testing, thermal cycling, and wear resistance evaluation. Thermal cycling between 65°C and 4°C simulates dishwasher operation cycles, while mechanical stress testing evaluates component integrity under repeated loading conditions.

Safety and Compliance Verification ensures materials meet food safety standards and regulatory requirements. NSF certification requirements mandate specific material properties for food contact surfaces, while Energy Star compliance depends partly on material thermal properties affecting energy consumption.

Dishwasher Quality Testing Methods Evaluation Matrix

Quality Calculation Methodology

Quantitative Assessment Framework

Professional dishwasher quality evaluation employs a multi-criteria scoring system that weights different performance factors according to their impact on overall appliance functionality. Material quality contributes 25% to the overall score, corrosion resistance accounts for 20%, with performance characteristics, durability, and cost-effectiveness contributing 15%, 15%, and 10% respectively.

Material Quality Scoring evaluates chemical composition accuracy, surface finish quality, and manufacturing consistency. Grade 316 typically scores 9.0/10 due to superior alloying content, while Grade 304 achieves 8.5/10 reflecting excellent general performance. Grade 306 scores 8.0/10 for specialized applications, and Grade 430 receives 7.0/10 for basic applications.

Corrosion Resistance Evaluation employs quantitative testing results to assign numerical scores. Critical pitting temperature measurements, salt spray test duration before first rust appearance, and electrochemical corrosion rates provide objective data for scoring. Grade 316 consistently achieves the highest scores (9.5/10) due to molybdenum content, while Grade 430 shows more limited performance (6.5/10).

Performance Integration combines cleaning efficiency, drying performance, and energy consumption data into composite scores. Stainless steel grades with superior heat retention properties achieve higher drying efficiency scores, while those with smoother surface finishes excel in cleaning performance metrics.

Practical Assessment Tools

Field Testing Protocols provide practical methods for evaluating installed dishwashers. Visual inspection techniques identify surface defects, corrosion initiation sites, and manufacturing inconsistencies. Magnetic testing distinguishes between austenitic and ferritic grades, while spark testing provides field-verification of basic composition.

Performance Benchmarking establishes comparative standards for different applications. Commercial dishwashers require higher performance thresholds than residential units, with scoring adjusted accordingly. Marine applications demand maximum corrosion resistance, while standard residential applications can accept more economical material choices.

Cost-Benefit Analysis integrates material costs with expected performance life to calculate total value proposition. While Grade 316 commands premium pricing, its extended service life and superior performance often justify the investment in demanding applications.

Professional Recommendations and Best Practices

Application-Specific Material Selection

Premium Applications requiring maximum durability and performance should specify Grade 316 stainless steel for all wetted components. This includes commercial dishwashers, marine applications, and high-end residential units where extended service life justifies higher material costs.

Standard Residential Applications achieve optimal cost-performance balance with Grade 304 stainless steel for interior components. This grade provides excellent corrosion resistance and performance characteristics while maintaining reasonable manufacturing costs.

Specialized Food Service Applications benefit from Grade 306 stainless steel for food contact surfaces, combined with Grade 304 for general interior components. This approach optimizes food safety compliance while controlling overall material costs.

Economy Applications can employ Grade 430 stainless steel for non-critical components while maintaining Grade 304 for primary wetted surfaces. This hybrid approach reduces material costs while preserving essential performance characteristics.

Quality Assurance Implementation

Incoming Material Inspection should verify grade specifications through analytical testing before manufacturing. X-ray fluorescence screening provides rapid verification, while detailed chemical analysis confirms critical alloying elements for production batches.

Process Control Monitoring tracks material performance throughout manufacturing, identifying welding, forming, or finishing processes that might compromise corrosion resistance. Proper heat treatment and surface passivation ensure optimal material performance.

Final Product Testing validates material selection through accelerated corrosion testing and performance verification. This ensures that theoretical material properties translate into actual appliance performance under real-world conditions.

Performance Optimization Strategies

Surface Finishing Optimization significantly impacts material performance regardless of grade selection. Proper electropolishing or passivation treatments enhance corrosion resistance and improve cleaning efficiency across all stainless steel grades.

Design Integration considers material properties in component design, optimizing drainage patterns, stress distribution, and thermal management. Superior materials cannot compensate for poor design practices that create corrosion-prone conditions.

Maintenance Integration provides end-users with appropriate care instructions specific to installed stainless steel grades. Different grades require different maintenance approaches to maintain optimal performance throughout service life.

Conclusion

Professional dishwasher quality assessment based on stainless steel grade selection requires comprehensive understanding of material properties, systematic testing methodologies, and practical evaluation frameworks. The choice between Grades 304, 306, 316, and 430 significantly impacts overall appliance performance, with each grade offering distinct advantages for specific applications.

Grade 316 provides superior performance for demanding applications, justifying premium costs through extended service life and enhanced corrosion resistance. Grade 304 offers excellent general performance for standard applications, providing optimal cost-performance balance for most residential installations. Grade 306 delivers specialized benefits for food contact applications, while Grade 430 provides economical solutions for non-critical components.

The systematic assessment framework presented in this report enables accurate quality evaluation and informed material selection decisions. By integrating material testing with performance evaluation and cost analysis, manufacturers and specifiers can optimize dishwasher design for specific applications while maintaining competitive market positioning.

Professional implementation of these assessment methodologies ensures that stainless steel selection contributes optimally to overall appliance quality, customer satisfaction, and long-term market success. The quantitative evaluation framework provides objective basis for material selection decisions while the practical testing procedures ensure real-world performance validation.