Before diving into invoices and spreadsheets, it helps to grasp the big picture. A commercial dishwasher is not an isolated appliance; it is a high-throughput sanitation system that dictates plumbing, electrics, workflow, ventilation, and chemical logistics throughout the back-of-house. Using real figures from recent UK projects, this report shows how to build a reliable cost model that captures both the one-off investment and the long-tail running expenses of an undercounter commercial unit.

Executive Summary

Professionals who underestimate installation logistics and lifetime utilities often overspend by 25-40 percent or, worse, select a unit that never pays for itself. A robust remodel budget must:

- Separate capital costs (equipment, fabrication, delivery, installation, compliance) from operating costs (energy, water, chemicals, preventive maintenance).

- Audit the kitchen’s existing utilities before purchase – relocating drainage or upsizing power supplies can exceed 30 percent of the machine price.

- Model costs on a per-rack basis to benchmark competing machines and quantify payback from energy-efficient features such as built-in heat recovery or low-litre rinse pumps.

- Include ventilation and booster-heater requirements early; these two hidden items account for up to half the electrical load.

1. Scoping a Dishwasher-Centric Remodel

1.1 Choose the Right Spec

- Ware volume: Calculate daily rack demand (dirty plate count ÷ 18 for 500 mm baskets). Add a 15 percent peak buffer.

- Wash temperature: Decide between low-temp chemical (cheaper capital, higher chem cost) and high-temp (needs 82 °C rinse, typically via booster heater).

- Electrical supply: Undercounter UK models draw 3–7 kW, single or three-phase. Confirm board capacity and breaker rating in advance.

- Water hardness: Sites over 100 ppm require a built-in or external softener to protect rinse jets and heating elements.

1.2 Spatial Integration

- Allow at least 600 mm clear sides for service access.

- Position inlet/outlet services within 1 m of the machine to avoid expensive trenching.

- Ensure adjacent tabling forms a straight-line flow from scrape to rack to dry.

1.3 Codes and Compliance

- WRAS backflow prevention, BS 6173 for gas-interlocked hoods, and building-control sign-offs are non-negotiable.

- A Commercial Catering (CCNSG) electrician and a Gas Safe engineer must sign utility alterations. Budget accordingly.

2. Capital Expenditure Breakdown

| Cost Item | Typical Range (UK, 2025) | Notes |

|---|---|---|

| Undercounter dishwasher (500 mm basket, internal softener) | £2,300 – £3,200 | ENERGY STAR-rated models trending toward £2.8k |

| Booster heater (if high-temp) | £2,000 – £3,000 | Electric 6-12 kW wall-mount |

| Stainless fabrication (infeed/outfeed tabling, scrap sink) | £1,000 – £2,000 | Custom corners raise price |

| Electrical upgrade & isolation switch | £450 – £850 | Three-phase pull and RCD |

| Plumbing & waste modifications | £350 – £700 | Includes trap, tundish, tundish drain |

| Commissioning, detergents starter pack, operator training | £250 – £400 | Often bundled |

| Approx. capital total | £6,350 – £10,000 | Project-specific |

Tip: pre-quote every trade. Plumbers in the South East average £60 h⁻¹; electricians £50 h⁻¹. Night or weekend work attracts 50–100 percent premiums.

3. Annual Operating Costs

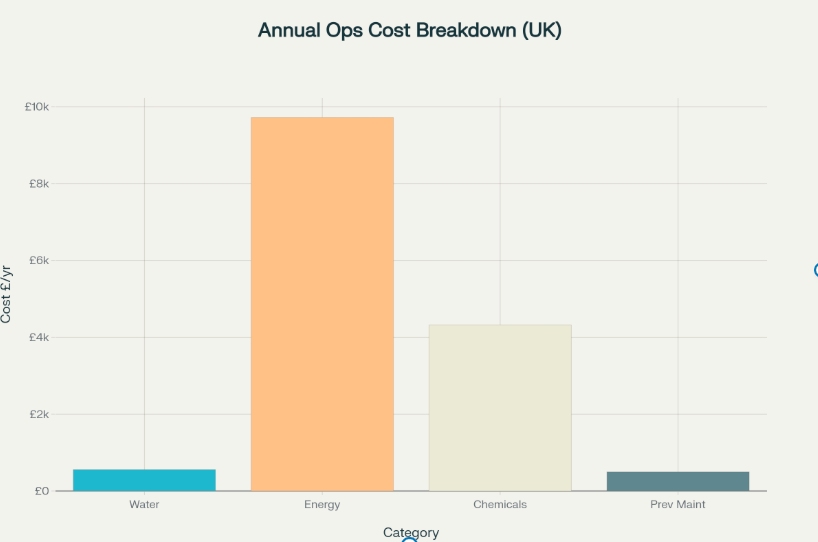

Energy and chemicals outrun the purchase price within the first 18 months. Calculations below assume 120 racks per day, 360 days a year, high-temperature cycle, and July 2025 UK utilities:

- Water & sewerage: 6 L per rack × £2.16 m⁻³.

- Electricity: 0.9 kWh per rack × £0.25 kWh⁻¹.

- Chemicals: £0.10 per rack (detergent, rinse aid, sanitizer).

- Planned maintenance: £500 per year (descale, dosing pump kits).

Combined, the operation totals roughly £15,100 per year.

Annual operating costs for a typical UK undercounter commercial dishwasher installed in a refurbished kitchen

Sensitivity Check

- Lowering incoming water to 55 °C via heat recovery trims electric use by 15–20 percent.

- Switching to low-temp chemical drops kWh by 30 percent but doubles chemical spend; net saving depends on regional tariffs.

4. Seven-Year Lifecycle Projection

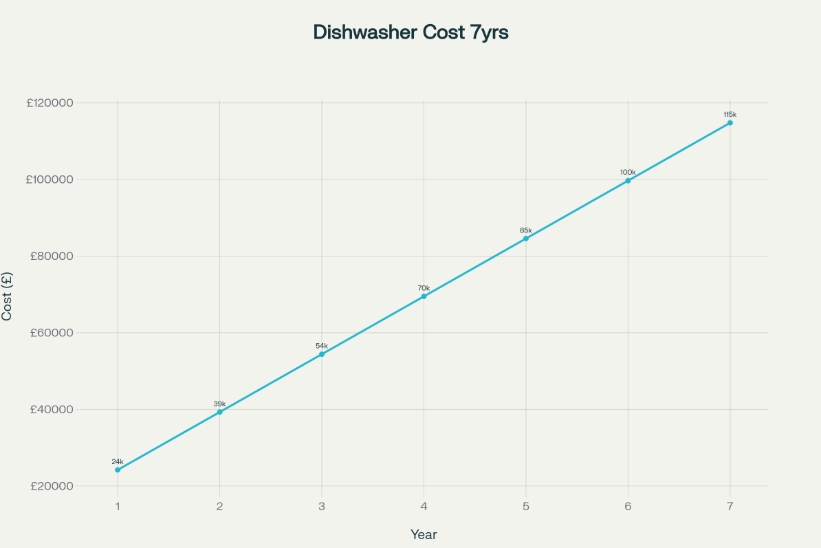

Assuming a seven-year depreciation schedule and no major repairs, the cumulative spend reaches almost £115 k – with only 8 percent attributable to the initial purchase.

Cumulative cash outlay from purchase through seven years: the first 9.1K represents upfront investment; operating costs dominate thereafter

Observation: the capital cost is eclipsed before the end of Year 1. Procurement teams should therefore rank units on kWh and litre-per-rack metrics, not sticker price.

5. Embedding Dishwasher Costs into the Wider Remodel

5.1 Ventilation & HVAC

- Canopy extension: Many UK insurers now require a dedicated Type B hood over dish areas. Linear footage runs £950 – £1,200 per metre installed.

- Make-up air: Factor an extra 20 percent airflow in winter calculations to offset steam egress.

5.2 Flooring & Drainage

- Quarry tile slopes of 1:80 toward a stainless gully keep the site compliant with slip-resistance regulations. Rescreeding 5 m² costs £800 – £1,000.

5.3 Contingency and Project Management

Set aside 10 percent contingency for unforeseen cable reroutes or anti-microbial wall cladding.

6. Quick-Reference Costing Worksheet

- Determine daily rack volume (R).

- Compute utilities

- Water cost = R × 6 L × 0.001 m³ × regional £/m³.

- Energy cost = R × kWh per rack × £/kWh.

- Chemical cost = R × £ per rack.

- Add fixed annual charges (maintenance, standing electricity & water charges).

- Sum annual operating cost (O).

- Capital cost (C) = equipment + fabrication + services + compliance.

- Lifetime spend = C + (O × years).

- Cost per clean rack = lifetime spend ÷ (R × years).

- Compare scenario A vs B to justify premium features.

Worked Example

- R = 120, C = £9,100, O ≈ £15,100, years = 7.

- Lifetime ≈ £114,800.

- Cost per rack ≈ £3.65.

7. Cost-Control Tactics without Performance Sacrifice

- Opt for ENERGY STAR or WRAS-approved low-rinse models; 1 L shaved per rack saves ~£300 annually.

- Install an external detergent doser linked to rack counter to avoid over-dosing.

- Specify auto-start and idle shut-off to eliminate overnight heating.

- Bundle preventive maintenance in a multiyear service agreement – annualised cost is lower than call-outs.

- Retrofit drain heat recovery if capex limits prevented purchasing heat-recovery dishwasher; payback in ~18 months at current kWh tariffs.

Conclusion

A dishwasher-centric remodel hinges less on headline equipment price and more on the supporting infrastructure and long-run utility profile. By quantifying costs per rack and modelling seven-year cash flow, decision-makers can clearly see where to spend and where to save. Integrating the dishwasher early into kitchen layout, utilities planning, and ventilation design prevents costly re-work and ensures the investment delivers hygienic, efficient service shift after shift.