The dishwasher manufacturing industry is experiencing unprecedented transformation as businesses increasingly recognize the strategic value of establishing direct partnerships with factory producers 1. This shift represents more than cost optimization; it fundamentally reshapes how companies approach quality control, innovation access, and supply chain management in an era of heightened competition and technological advancement. Modern manufacturing facilities have evolved into sophisticated production environments where cutting-edge automation meets precision engineering, creating opportunities for deeper collaboration between buyers and producers.

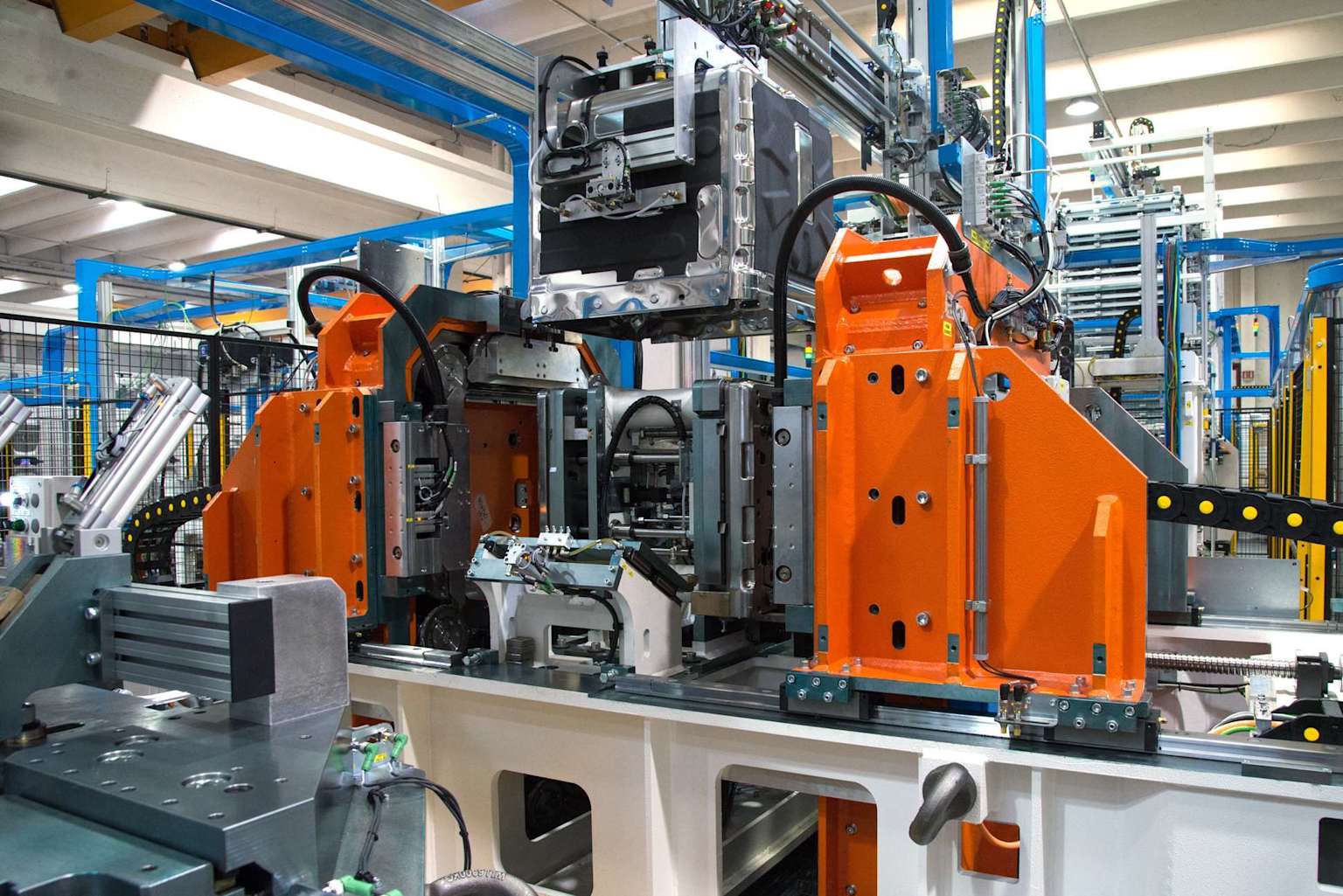

A modern, automated production line for dishwasher tub manufacturing within a factory

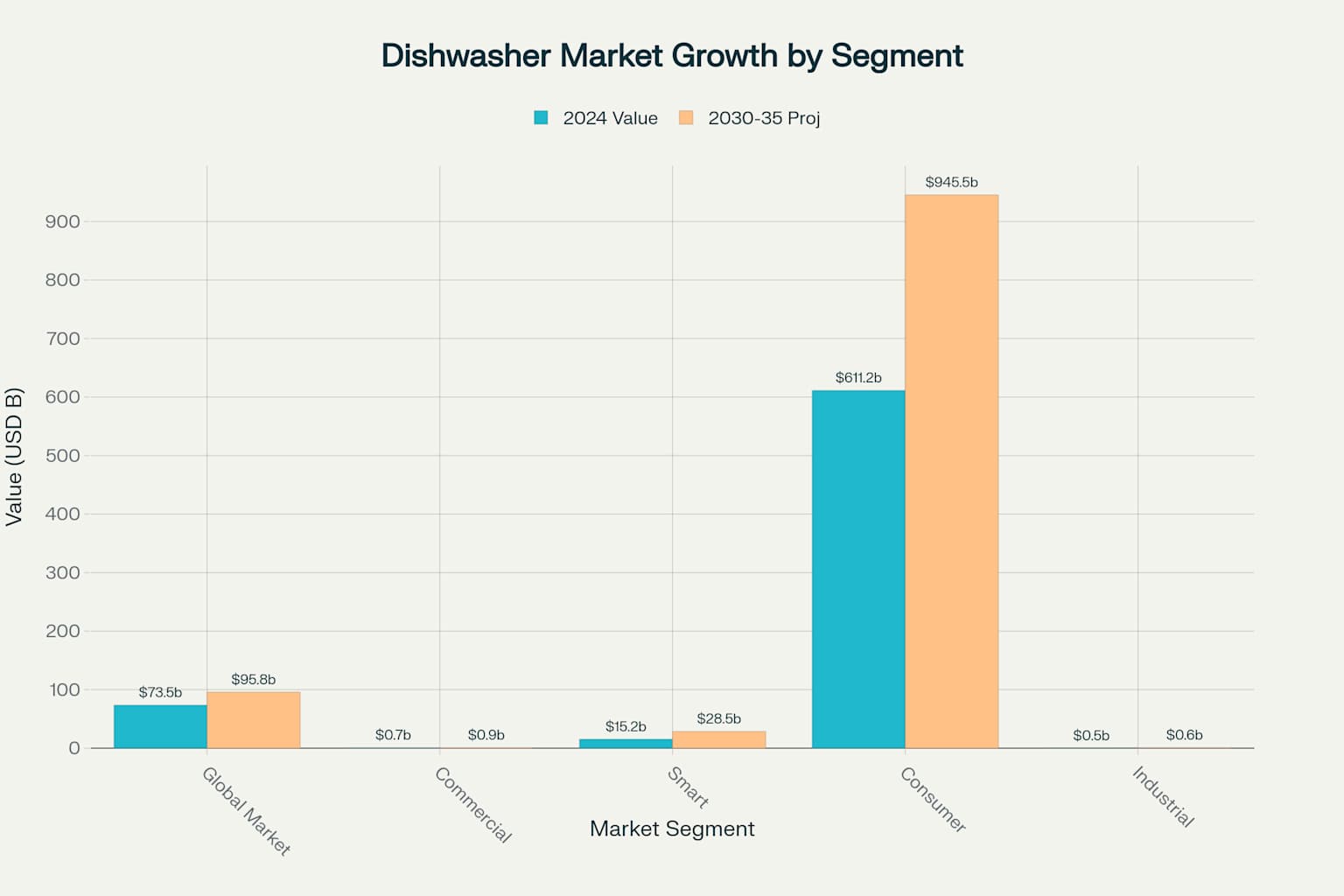

The global dishwasher market, valued at $73.5 billion in 2024, is projected to reach $95.8 billion by 2030-2035, driven primarily by smart technology adoption and sustainability initiatives. This growth trajectory, combined with the increasing complexity of commercial and industrial dishwashing solutions, makes direct factory partnerships not just advantageous but strategically essential for businesses seeking competitive differentiation.

Market Landscape and Manufacturing Evolution

The dishwasher manufacturing sector has undergone remarkable transformation, with commercial dishwashers representing a $728 million market in 2024, expected to grow at a 4.5% compound annual growth rate through 2030. Industrial dishwashers, while representing a smaller segment at $454 million, demonstrate the specialized nature of manufacturing partnerships required for complex commercial applications. The emergence of smart dishwashers as the fastest-growing segment, with a projected 10.8% CAGR, underscores the importance of maintaining direct connections with innovative manufacturers.

Market growth projections for different dishwasher segments from 2024 to 2030-2035

Modern dishwasher factories exemplify Industry 4.0 principles, incorporating artificial intelligence, robotic automation, and advanced sensor technologies into their production processes 9. These facilities utilize sophisticated quality control systems, automated assembly lines, and real-time monitoring capabilities that enable unprecedented levels of customization and quality assurance. Leading manufacturers such as Samsung, LG Electronics, Electrolux Professional, and Hobart have invested heavily in advanced manufacturing technologies, creating opportunities for direct partnerships that leverage these capabilities.

Automated machinery on a modern dishwasher production line

Cost Optimization Through Direct Factory Partnerships

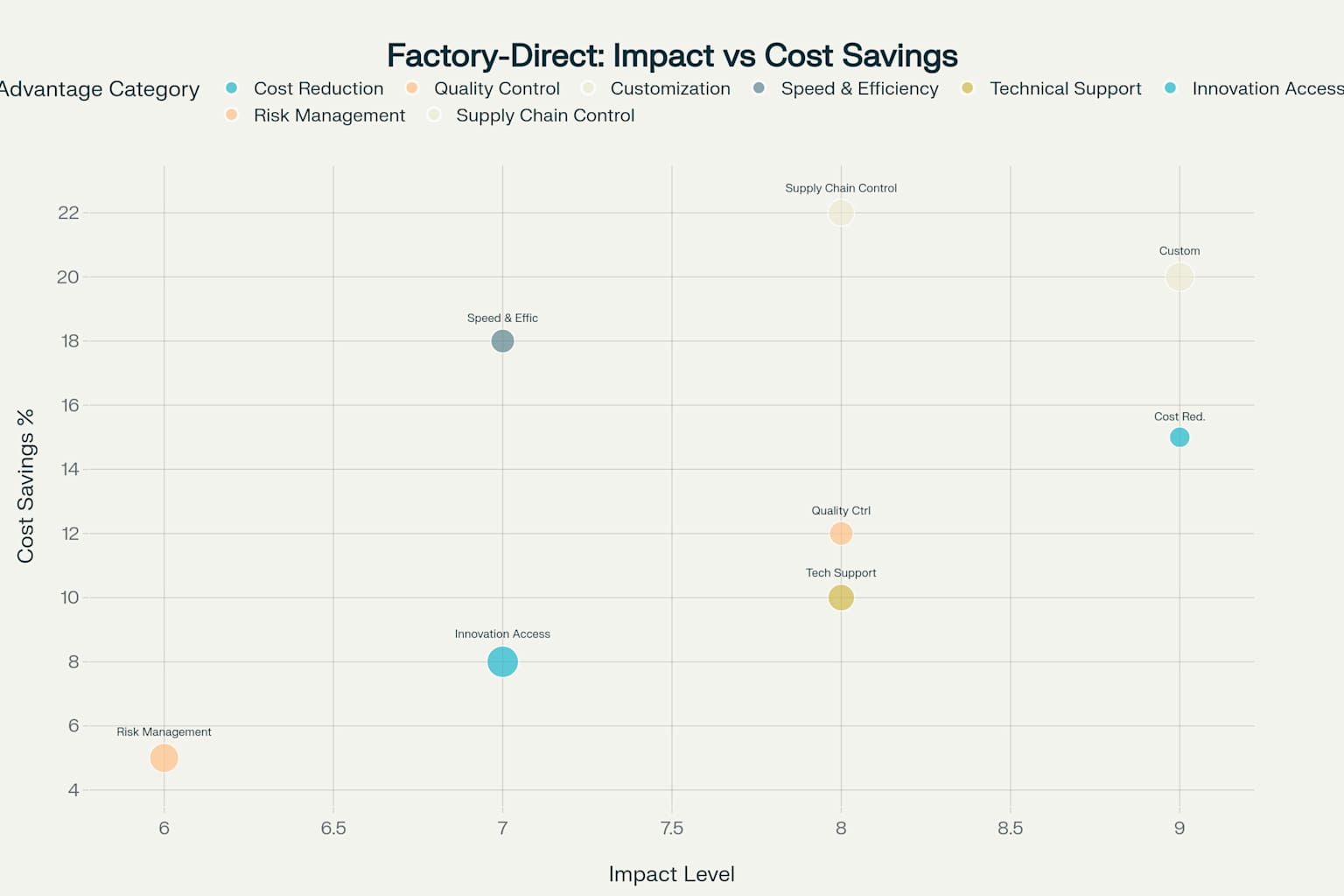

The financial advantages of eliminating intermediaries extend far beyond simple markup reductions, encompassing comprehensive cost structure optimization that can deliver 15-30% savings in total procurement expenses. Direct sourcing eliminates multiple layers of distribution costs, including distributor margins, handling fees, storage expenses, and administrative overhead that accumulates through traditional supply chains. These savings compound significantly over large-volume purchases, making factory-direct partnerships particularly attractive for businesses with substantial dishwasher requirements.

Price transparency represents a critical advantage of direct partnerships, providing buyers with complete visibility into manufacturing costs, material expenses, and production processes. This transparency enables informed decision-making and strategic planning that is impossible when working through intermediaries who may restrict access to detailed cost breakdowns. Volume discounts become more meaningful through direct negotiation, as manufacturers can offer pricing structures based on actual production economics rather than distributor pricing policies.

Analysis of factory-direct partnership advantages showing the relationship between impact level and cost savings potential

The cost-effectiveness extends to operational efficiency, where direct partnerships enable just-in-time production scheduling that reduces inventory carrying costs and minimizes waste. Strategic sourcing through factory-direct channels allows businesses to optimize their total cost of ownership by considering factors such as energy efficiency, maintenance requirements, and product longevity in their purchasing decisions.

Quality Control and Manufacturing Excellence

Direct factory partnerships provide unparalleled access to quality control processes, enabling buyers to participate actively in production oversight and quality assurance protocols. Unlike traditional purchasing relationships where quality depends on third-party certifications and limited inspection opportunities, direct partnerships offer comprehensive access to factory testing facilities, production line monitoring, and real-time quality metrics. This direct oversight capability proves particularly valuable for commercial and industrial dishwasher applications where performance reliability directly impacts operational efficiency.

A stainless steel commercial dishwasher with loaded racks of plates, designed for industrial kitchen use

Customization capabilities represent a significant competitive advantage of factory-direct partnerships, allowing businesses to specify exact requirements for materials, features, functionality, and design elements. Manufacturing partners can accommodate specialized requirements such as specific wash cycle configurations, energy efficiency standards, or integration capabilities that may not be available through standard product lines. This customization extends to compliance requirements, where direct partnerships ensure products meet specific regulatory standards, safety certifications, and industry specifications.

The quality assurance benefits compound through direct communication channels that enable rapid problem resolution and continuous improvement initiatives. When quality issues arise, direct partnerships allow immediate escalation to engineering teams and production managers who can implement corrective actions without the delays inherent in multi-layered distribution relationships. This responsiveness proves crucial for maintaining operational continuity and ensuring consistent product performance.

Technical Support and Innovation Access

Factory-direct partnerships provide privileged access to technical expertise that extends far beyond basic product support, encompassing engineering consultation, application-specific guidance, and collaborative problem-solving. Manufacturers’ technical teams possess deep knowledge of product capabilities, installation requirements, maintenance protocols, and optimization strategies that may not be available through distributor technical support. This expertise proves invaluable for complex commercial installations where proper configuration and operation directly impact performance outcomes.

Innovation access represents a strategic advantage of direct manufacturer relationships, providing early exposure to emerging technologies, product developments, and industry trends. Leading dishwasher manufacturers invest heavily in research and development, incorporating advanced features such as AI-powered wash cycles, IoT connectivity, energy optimization systems, and sustainable operation modes. Direct partnerships often include opportunities for collaborative innovation, where manufacturers work with key customers to develop customized solutions or test new technologies.

A complete commercial kitchen dishwashing station featuring an industrial hood-type dishwasher, pre-rinse sink, and dish rack storage

Technical training and education programs offered by manufacturers ensure optimal product utilization and maintenance practices that maximize equipment lifespan and performance. These comprehensive training initiatives cover installation procedures, operation optimization, troubleshooting protocols, and preventive maintenance practices that may not be available through traditional distribution channels. The documentation and technical resources provided directly by manufacturers offer complete specifications, detailed operation manuals, and comprehensive troubleshooting guides that support long-term success.

Supply Chain Efficiency and Risk Management

Direct manufacturing partnerships significantly enhance supply chain visibility and control, providing end-to-end transparency that enables proactive management of potential disruptions. Unlike traditional distribution relationships where supply chain visibility extends only to the first tier of suppliers, direct partnerships offer comprehensive insight into raw material sourcing, production scheduling, quality control processes, and logistics coordination. This transparency enables better demand forecasting, inventory optimization, and risk assessment capabilities.

Modern factory assembly line with multiple parallel conveyor belt systems

Lead time optimization represents a tangible benefit of direct partnerships, where streamlined communication and elimination of intermediary processing steps can reduce delivery times by 20-40%. Manufacturers can prioritize production scheduling for direct partners, accommodate rush orders when necessary, and provide accurate delivery forecasts based on actual production capacity. This responsiveness proves particularly valuable for businesses with seasonal demand patterns or project-based requirements.

Risk management capabilities improve significantly through direct partnerships, where manufacturers and buyers can collaborate on contingency planning, alternative sourcing strategies, and supply chain resilience initiatives. Direct communication enables rapid response to potential disruptions, whether from material shortages, production issues, or logistics challenges. The simplified supply chain structure reduces points of failure and eliminates dependencies on intermediary relationships that may introduce additional risks.

Implementation Strategies for Successful Partnerships

Successful factory-direct partnerships require strategic planning, clear communication protocols, and systematic relationship management approaches that ensure mutual benefit and long-term sustainability. The implementation process typically begins with comprehensive manufacturer evaluation, assessing production capabilities, quality systems, technical expertise, and cultural compatibility. Key selection criteria include manufacturing capacity, technological advancement, quality certifications, financial stability, and alignment with business objectives.

An isometric illustration depicting a business handshake over a contract, symbolizing direct collaboration and partnership agreements

Communication infrastructure development proves critical for partnership success, establishing regular review meetings, performance metrics, feedback mechanisms, and escalation procedures that maintain alignment and address issues proactively. Clear specification of requirements, quality standards, delivery expectations, and performance measures ensures mutual understanding and accountability throughout the relationship. Cultural considerations become particularly important for international partnerships, where understanding business practices, communication styles, and decision-making processes facilitates effective collaboration.

Performance monitoring and continuous improvement initiatives maintain partnership effectiveness over time, utilizing metrics such as quality performance, delivery reliability, cost competitiveness, and innovation contribution. Regular business reviews provide opportunities to assess partnership performance, identify improvement opportunities, and align on future objectives and requirements. Successful partnerships evolve beyond transactional relationships to become strategic alliances that drive mutual growth and competitive advantage.

Future Outlook and Emerging Technologies

The dishwasher manufacturing industry continues evolving toward greater automation, sustainability, and technological integration, creating new opportunities for strategic partnerships between manufacturers and buyers. Digital transformation initiatives within manufacturing facilities are enhancing production efficiency, quality control capabilities, and customization flexibility through Industry 4.0 technologies. These advancements include artificial intelligence applications, predictive maintenance systems, and digital twin technologies that optimize production processes and product performance.

Smart dishwasher technologies represent the fastest-growing market segment, with AI-powered features, IoT connectivity, and automated operation modes becoming standard expectations rather than premium options. Manufacturers are investing heavily in sensor technologies, machine learning algorithms, and cloud-based management systems that enable remote monitoring, predictive maintenance, and operational optimization. Energy efficiency innovations continue advancing through improved motor technologies, heat recovery systems, and water management solutions that reduce environmental impact while lowering operating costs.

Sustainability initiatives are reshaping manufacturing processes and product designs, with increased focus on recyclable materials, energy-efficient operation, and extended product lifecycles. Leading manufacturers are implementing circular economy principles, designing products for disassembly and material recovery, and developing take-back programs that support environmental objectives. These sustainability initiatives create opportunities for partnerships that align with corporate environmental goals and regulatory requirements.

Strategic Implementation Framework

The transition to factory-direct partnerships requires systematic planning and execution that addresses organizational capabilities, supplier relationships, and operational processes. Successful implementation typically follows a phased approach that begins with pilot partnerships, demonstrates value through measurable results, and scales successful models across broader procurement categories. Organizations must develop internal capabilities for supplier management, quality oversight, and relationship coordination that may differ significantly from traditional procurement approaches.

Due diligence processes for manufacturer selection should evaluate production capabilities, quality systems, financial stability, technological advancement, and cultural compatibility. Site visits to manufacturing facilities provide firsthand insight into production processes, quality control systems, automation capabilities, and organizational culture that inform partnership decisions. Reference checks with existing customers offer additional perspective on manufacturer performance, reliability, and partnership satisfaction.

Contract structures for direct partnerships typically include pricing mechanisms, quality specifications, delivery requirements, intellectual property provisions, and performance metrics that protect both parties’ interests while enabling collaborative success. Service level agreements should address technical support, training provision, documentation requirements, and continuous improvement expectations that ensure partnership value realization. Regular performance reviews and relationship management processes maintain alignment and address emerging opportunities or challenges.

Conclusion

Factory-direct partnerships in the dishwasher manufacturing industry represent a strategic imperative rather than simply a cost optimization opportunity. The convergence of technological advancement, market growth, and competitive pressures creates compelling advantages for businesses that establish direct relationships with manufacturing partners. These partnerships enable comprehensive benefits including significant cost savings, enhanced quality control, accelerated innovation access, and improved supply chain resilience.

The evidence demonstrates that well-executed factory-direct partnerships can deliver 15-30% cost reductions while simultaneously improving quality outcomes, customization capabilities, and technical support access. As the dishwasher market continues evolving toward smart technologies, sustainability initiatives, and specialized applications, direct partnerships provide the agility and responsiveness necessary for competitive success. Organizations that embrace this approach position themselves to capitalize on emerging opportunities while building sustainable competitive advantages through strategic manufacturer relationships.

The future belongs to businesses that recognize manufacturing partnerships as strategic assets rather than transactional relationships, leveraging direct connections to drive innovation, optimize operations, and create value for customers and stakeholders. Success in this environment requires commitment to relationship building, investment in partnership management capabilities, and alignment around shared objectives that benefit all parties involved.