A Comprehensive Guide for Food Service Operations

Commercial dishwashers are the backbone of any successful food service operation, processing hundreds of dish cycles daily in restaurants, hotels, and institutional kitchens. Proper maintenance and quick troubleshooting are critical for ensuring consistent performance, meeting health code requirements, and avoiding costly downtime that can disrupt service and impact revenue.

Clean dishes and cutlery are loaded into a commercial dishwasher in a busy kitchen

Daily Maintenance: The Foundation of Equipment Longevity

Daily maintenance routines form the cornerstone of commercial dishwasher reliability and performance. These essential tasks, when performed consistently, prevent the majority of common operational issues and extend equipment lifespan significantly.

Essential Daily Cleaning Procedures

The most critical daily maintenance task involves emptying and thoroughly washing all dishwasher filters. Food debris and grease accumulation in filters creates the primary cause of drainage problems and reduces cleaning effectiveness. Remove filter cages, rinse under hot water, and scrub with a soft brush to eliminate all visible debris.

Interior surface cleaning must be performed after each shift to prevent bacterial growth and maintain sanitary conditions. Wipe down all interior walls, door seals, and accessible components with a non-foaming surface cleaner specifically designed for commercial dishwashers. Never use soap-based chemicals, as residual foam will compromise cleaning results.

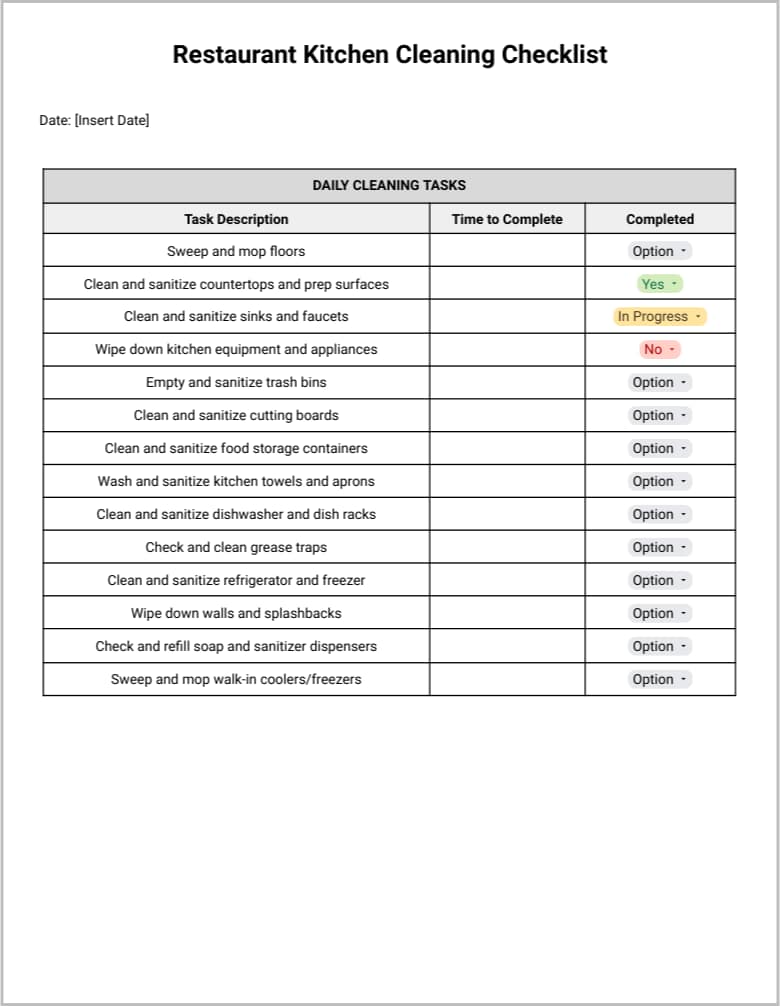

A daily cleaning checklist for a restaurant kitchen, including the task to clean and sanitize dishwashers and dish racks

Spray arm inspection and cleaning requires daily attention to ensure proper water circulation. Remove spray arms and check each nozzle for blockages caused by food particles or mineral deposits. Use a toothpick or small wire to clear blocked holes, ensuring unrestricted water flow during wash cycles.

External maintenance includes wiping down the dishwasher exterior and checking for visible leaks around door seals, water lines, and the base of the unit. Early leak detection prevents water damage and identifies developing seal problems before they require professional intervention.

Filter Maintenance Best Practices

Commercial dishwasher filters require specific handling procedures to maintain optimal performance. Most units feature two-part filter assemblies consisting of upper and lower components that must be removed, cleaned, and reinstalled in proper sequence. Turn the upper filter assembly counterclockwise a quarter turn for removal, then lift out the lower filter by grasping and pulling forward.

Clean filters under warm running water, using a soft brush to remove stubborn debris without damaging the mesh material. Inspect filters for tears, cracks, or excessive wear that could allow food particles to enter the wash system. Replace damaged filters immediately to prevent pump damage and maintain cleaning effectiveness.

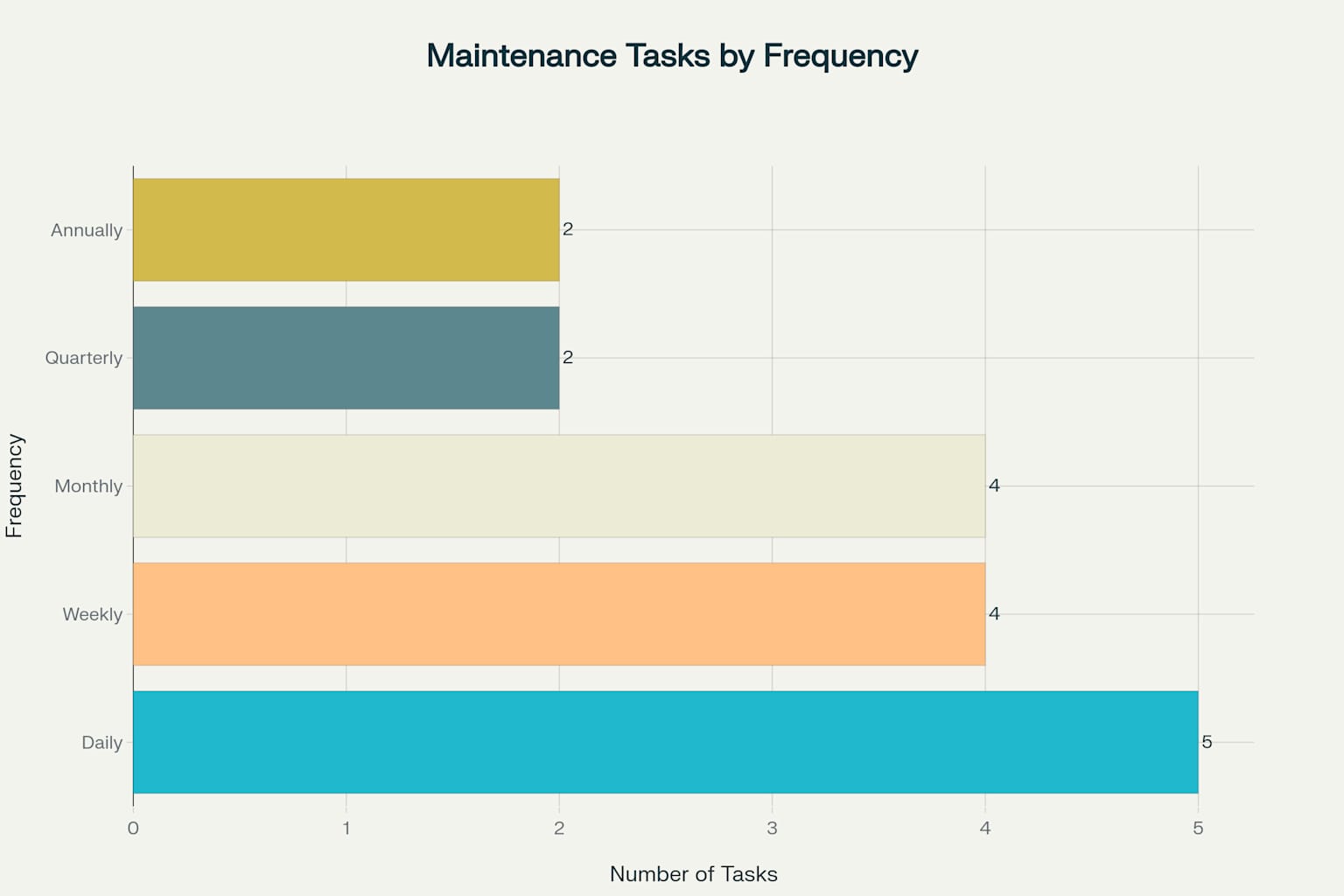

Commercial Dishwasher Maintenance Schedule – Tasks by Frequency

Common Problems Quick Reference Guide

Commercial dishwashers experience predictable failure patterns that kitchen staff can often resolve through systematic troubleshooting. Understanding these common issues enables faster problem resolution and reduces reliance on expensive service calls.

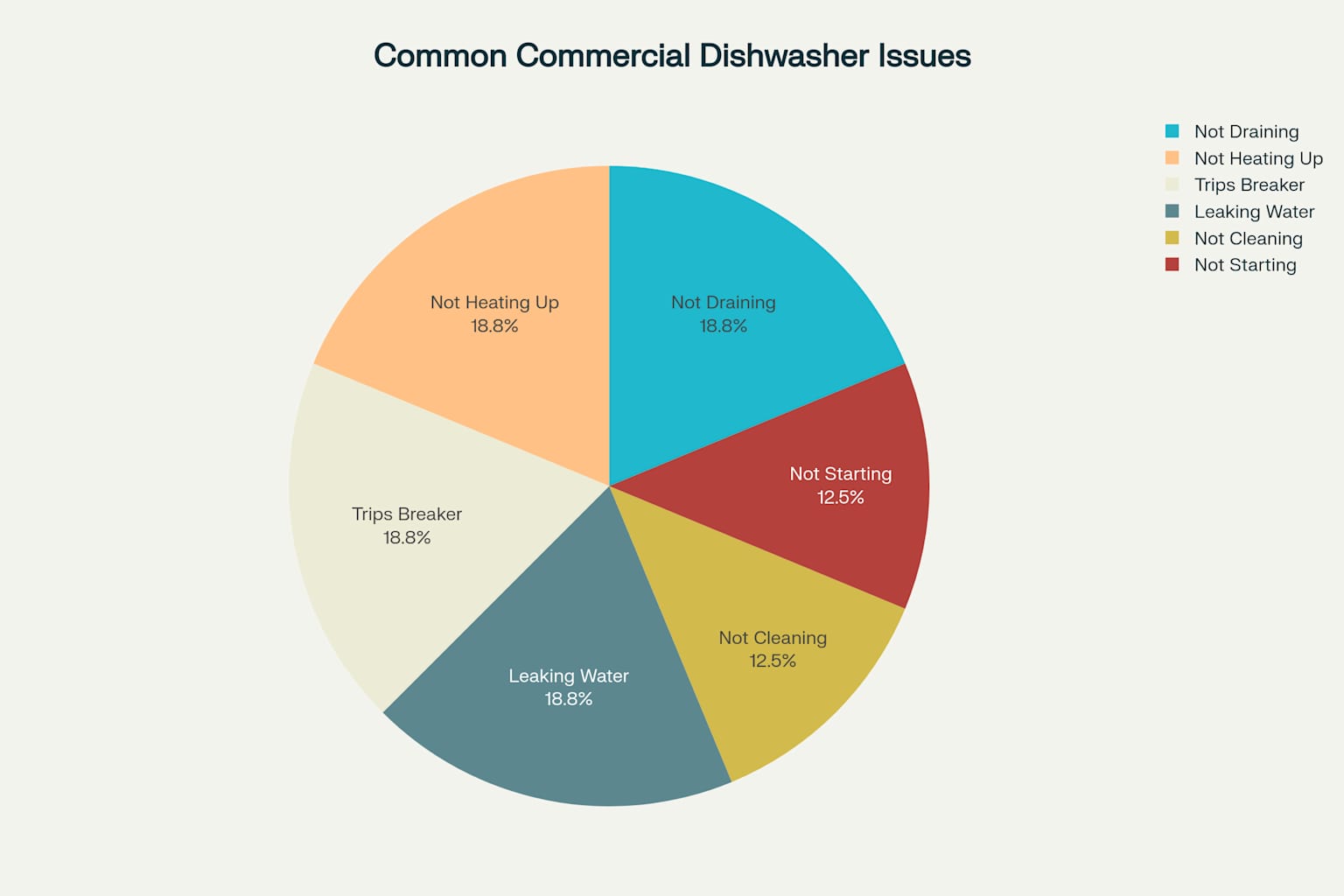

Most Common Commercial Dishwasher Problems Distribution

Drainage Problems: Not Draining Properly

Drainage issues represent the most frequent commercial dishwasher problem, typically caused by three primary factors. Clogged drain filters create the most common drainage obstruction, requiring immediate filter removal and thorough cleaning. Check drain hoses for kinks, food debris blockages, or improper installation that restricts water flow.

Faulty drain valves may stick in closed positions, preventing water evacuation from the wash tank. Test valve operation by manually checking bracket movement and ensuring free operation without binding. Replace malfunctioning drain valves to restore proper drainage function.

Prevention strategies include daily filter cleaning, regular drain line maintenance, and monthly valve operation checks. Contact professional service when problems persist after basic cleaning or when multiple blockages indicate complex plumbing issues.

Heating Problems: Not Heating Up Properly

Temperature-related problems significantly impact cleaning effectiveness and sanitation compliance. Defective heating elements represent the primary cause of inadequate water heating, requiring multimeter testing to verify electrical continuity. Commercial dishwashers require wash temperatures of 150-160°F and rinse temperatures of 180°F for proper sanitization.

Incorrect incoming water temperature affects overall heating performance and cycle efficiency. Monitor water supply temperature and ensure adequate hot water availability before starting wash cycles. Faulty thermostats may prevent proper temperature regulation, requiring professional diagnosis and replacement.

Regular descaling prevents mineral buildup that reduces heating element efficiency and prolongs heating cycles. Annual professional inspections identify developing temperature control problems before they cause complete heating system failure.

Electrical Issues: Keeps Tripping Breaker

Circuit breaker tripping indicates electrical problems requiring immediate attention for safety and operational continuity. Overloaded circuits cause the most common breaker trips, especially when dishwashers share circuits with other high-amperage appliances. Install dedicated circuits for commercial dishwashers to prevent electrical overloads.

Faulty heating elements drawing excessive amperage trigger circuit protection devices during heating cycles. Test heating element amperage to identify components exceeding normal operating parameters. Damaged internal wiring or loose electrical connections create dangerous conditions requiring immediate professional intervention.

Water infiltration into electrical components causes dangerous short circuits and immediate breaker trips. Inspect for dampness around electrical panels and motor housings, addressing any moisture sources immediately. Never operate dishwashers with suspected electrical problems, as this creates serious safety hazards.

Water Leakage: Identifying and Resolving Leaks

Water leaks threaten food safety, create slip hazards, and indicate developing equipment problems requiring prompt attention. Worn door seals and gaskets represent the most common leak sources, particularly around dishwasher doors during operation. Clean door seals daily and inspect for cracks, gaps, or deterioration that compromises the watertight seal.

Cracked hoses or loose fittings cause leaks at water supply and drain connections. Inspect all visible hoses for deterioration, tighten loose connections, and replace damaged components immediately. Ensure proper hose clamp installation and positioning to prevent connection failures.

Clogged drainage systems create overflow conditions that appear as leaks around the dishwasher base. Clean drains regularly and ensure proper water flow to prevent backup conditions. Address persistent drainage issues through professional service to prevent water damage and equipment failure.

Comprehensive Maintenance Schedule

Systematic maintenance scheduling ensures all critical components receive appropriate attention at optimal intervals. Daily tasks focus on immediate operational requirements and basic cleanliness, while weekly procedures address deeper cleaning and component inspection. Monthly maintenance includes descaling, water softener service, and detailed component cleaning that requires equipment downtime.

Quarterly professional services provide comprehensive system evaluation and address accumulated maintenance needs beyond routine cleaning. Annual inspections by qualified technicians identify developing problems, calibrate controls, and replace worn components before failures occur.

Regular maintenance scheduling reduces emergency service calls by 70% and extends equipment lifespan significantly compared to reactive maintenance approaches. Document all maintenance activities to track component performance, identify recurring problems, and maintain warranty compliance.

Professional Service: When to Call the Experts

A technician performing repair work on a residential dishwasher in a kitchen setting

Commercial dishwasher repair requires specialized knowledge, diagnostic equipment, and access to manufacturer-specific parts. Professional service becomes essential when basic troubleshooting fails to resolve problems or when electrical, plumbing, or mechanical repairs exceed in-house capabilities.

Recognizing Service Requirements

Complex electrical problems, including control board failures, motor issues, and heating element replacements, require professional diagnosis and repair. Water system modifications, including plumbing connections, drain line repairs, and pressure adjustments, need qualified technicians with commercial equipment experience.

Recurring problems despite proper maintenance indicate underlying system issues requiring professional investigation. Temperature calibration, chemical feed system adjustments, and warranty service must be performed by authorized service providers to maintain equipment certification.

Benefits of Professional Maintenance

Regular professional service prevents minor issues from developing into major failures that disrupt kitchen operations. Qualified technicians identify potential problems during routine inspections, allowing scheduled repairs during slow periods rather than emergency service during peak operations.

Professional service providers maintain relationships with parts suppliers, ensuring rapid access to manufacturer-specific components that minimize downtime. Proper documentation of professional service maintains warranty coverage and provides verification of compliance with health department requirements.

Conclusion

Effective commercial dishwasher maintenance combines consistent daily routines with systematic troubleshooting and professional service support. Daily filter cleaning, interior sanitization, and leak inspections prevent the majority of operational problems while maintaining health code compliance. Quick reference troubleshooting guides enable kitchen staff to resolve common drainage, heating, electrical, and leakage issues without service delays.

Professional service partnerships ensure complex repairs receive expert attention while maintaining equipment warranties and operational certifications. Investment in proper maintenance reduces total cost of ownership through extended equipment life, improved energy efficiency, and reduced emergency repair expenses. Successful food service operations recognize commercial dishwasher maintenance as essential infrastructure support that directly impacts customer satisfaction and business profitability.