Operating a commercial dishwasher effectively requires understanding the critical relationship between proper chemical selection and essential accessories. In high-volume foodservice environments, the success of warewashing operations depends on implementing systematic approaches to chemical management, equipment maintenance, and accessory utilization. Professional kitchen operators must balance cleaning efficiency, food safety compliance, and equipment longevity through strategic chemical selection and proper accessory deployment.

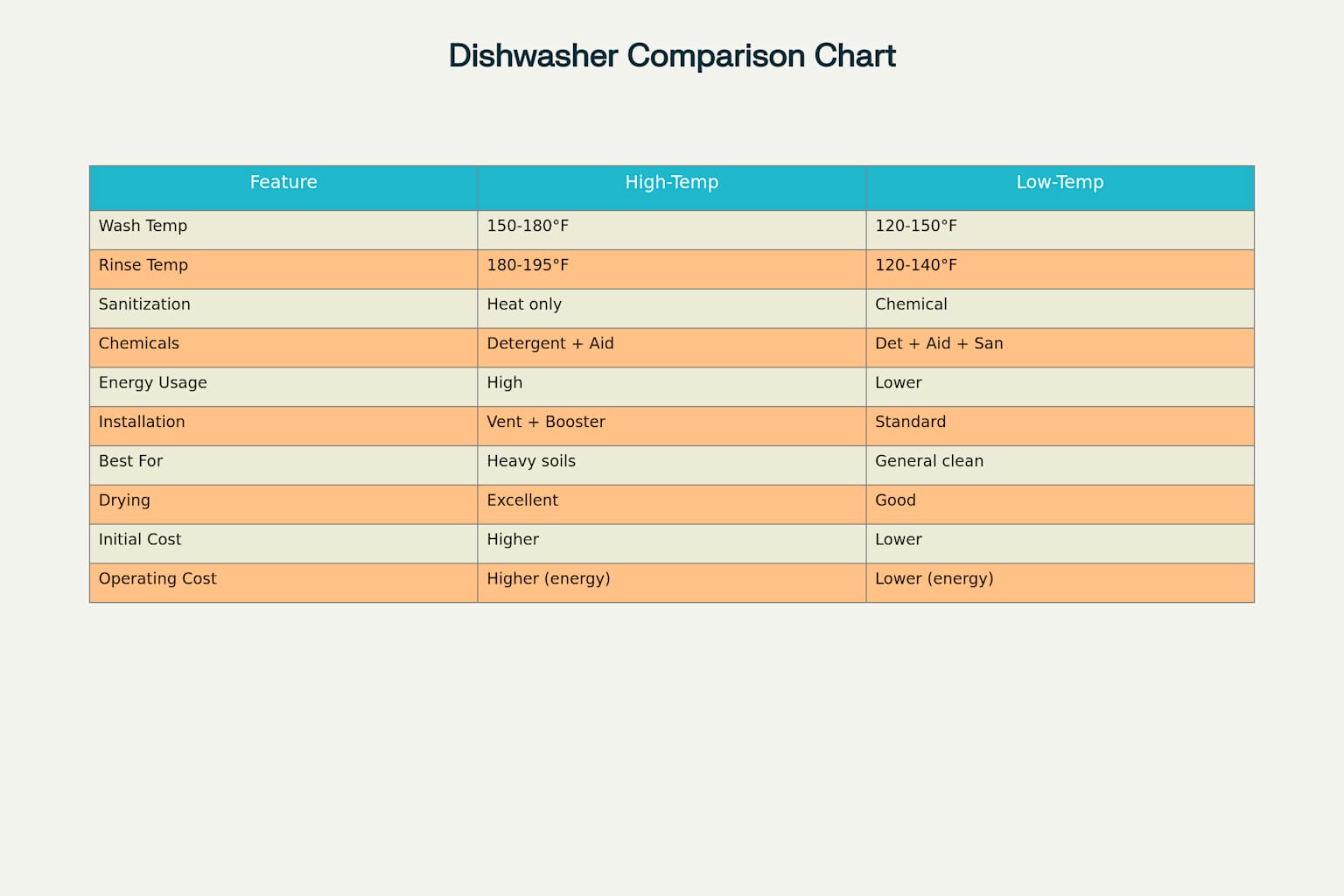

Comprehensive comparison of high-temperature vs low-temperature commercial dishwashers showing key operational differences

Commercial Dishwasher Detergents: Foundation of Effective Cleaning

Understanding Detergent Types and Applications

Commercial dishwasher detergents form the cornerstone of effective warewashing operations, with formulations specifically designed to handle the demanding requirements of professional kitchens. Unlike household detergents, commercial formulations contain concentrated active ingredients that function effectively in short wash cycles typical of high-volume operations.

Liquid detergents represent the most versatile option for commercial operations, offering compatibility with both high and low-temperature machines. These formulations typically contain anionic surfactants such as Sodium Lauryl Sulfate (SLS) or Linear Alkylbenzene Sulfonate (LABSA) as primary cleaning agents, with concentrations ranging from 10-15% by weight. Professional operators report optimal results when maintaining detergent concentrations between 2-4 g/L, though exact dosing depends on water hardness and soil levels.

Powder detergents excel in applications requiring heavy-duty cleaning with bleaching action, particularly effective against protein-based soils and staining. These formulations incorporate enzymes that break down fats and proteins while bleaching agents combat discoloration. However, powder detergents require careful handling due to potential respiratory irritation from airborne particles.

Water Hardness Considerations and Formulation Selection

Water quality significantly impacts detergent performance, with hard water requiring specialized formulations containing water-softening agents. Professional experience demonstrates that hard water areas benefit from detergents incorporating chelating agents like EDTA-2Na at concentrations of 0.1-0.5% to prevent mineral interference with cleaning action. Operators in soft water areas can utilize standard formulations, though monitoring remains essential to prevent over-dosing.

Chlorinated versus non-chlorinated detergent selection depends on specific operational requirements and equipment compatibility. Chlorinated formulations provide excellent destaining capabilities but should be avoided when washing precious metals or in facilities with high iron content in water supplies. Non-chlorinated alternatives offer safer handling characteristics while maintaining effective cleaning performance.

Rinse Aid: Optimizing Drying Performance and Spot Prevention

Understanding Rinse Aid Functionality

Rinse aid serves as a critical component in achieving professional dishwashing results, functioning primarily as a surfactant that reduces water surface tension. This reduction enables water to sheet off dishes rather than forming droplets, preventing mineral deposits and water spots while accelerating drying times. Professional operators consistently report that proper rinse aid application reduces drying time by 30-40% compared to operations without rinse aid.

The primary active ingredients in commercial rinse aids include nonionic surfactants, typically alcohol ethoxylates, which constitute approximately 10% of the formulation with the remaining 90% being water. These surfactants break the molecular bonds between water and dish surfaces, enabling rapid water drainage and preventing droplet formation. Optimal concentration ranges between 0.3-0.5 g/L for most commercial applications.

Selection Criteria and Application Methods

Effective rinse aid selection requires consideration of water hardness, machine type, and operational volume. Hard water environments benefit from rinse aids containing scale-controlling agents that prevent mineral buildup in rinse jets and internal components. Professional operators report optimal results when adjusting rinse aid concentration based on visible performance indicators rather than relying solely on manufacturer recommendations.

Modern commercial dishwashers feature automated dispensing systems that release precise amounts during final rinse cycles. Proper calibration ensures consistent application without waste or inadequate coverage. Visual indicators such as excessive foam suggest over-dosing, while water spots or slow drying indicate insufficient rinse aid concentration.

Sanitizers: Essential Chemical Sanitization for Low-Temperature Machines

Low-Temperature Sanitization Requirements

Low-temperature commercial dishwashers rely entirely on chemical sanitizers to achieve required sanitization standards, as wash and rinse temperatures between 120-150°F cannot provide thermal sanitization. The FDA Food Code mandates specific sanitizer concentrations and contact times to ensure effective pathogen elimination. Professional operators must maintain vigilant monitoring of sanitizer levels to ensure continuous compliance with health regulations.

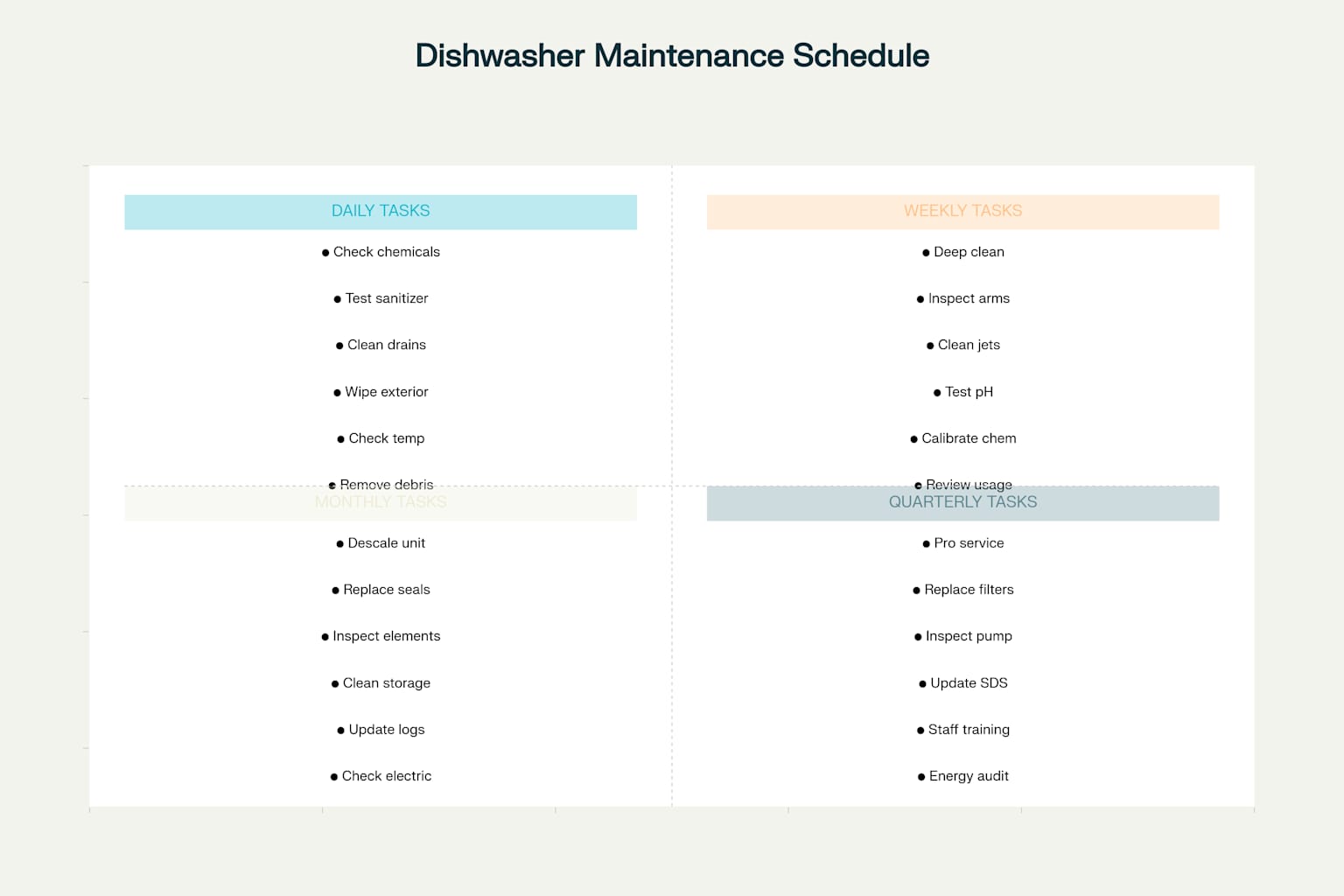

Commercial dishwasher maintenance schedule showing daily, weekly, monthly, and quarterly tasks for optimal performance

Chlorine-Based Sanitizers

Sodium hypochlorite represents the most widely used sanitizer in low-temperature commercial dishwashers, requiring concentrations between 50-100 ppm for effective sanitization. Professional experience demonstrates that maintaining chlorine levels at 100 ppm provides optimal antimicrobial action while ensuring adequate safety margins. Test strips enable rapid verification of chlorine concentration at the point of use during final rinse cycles.

Chlorine sanitizers offer broad-spectrum antimicrobial activity against bacteria, viruses, and fungi. However, operators must exercise caution as chlorine can form hazardous gases when mixed with acids or other chemicals. Proper ventilation and chemical storage protocols prevent dangerous reactions while maintaining effective sanitization.

Quaternary Ammonium Sanitizers

Quaternary ammonium compounds (quats) provide an alternative sanitization method for facilities requiring gentler chemical handling. These sanitizers require higher concentrations, typically 200-400 ppm, but offer improved surface compatibility and reduced odor compared to chlorine-based alternatives. Professional operators appreciate quats’ fabric-safe properties and reduced corrosive potential.

Quats demonstrate effectiveness against enveloped viruses and most bacteria, though they show reduced efficacy against gram-negative bacteria and bacterial biofilms. Proper application requires attention to contact time and concentration, with most formulations requiring 45-60 seconds contact time for effective sanitization.

Descalers and Delimers: Maintaining Equipment Performance

Understanding Scale Formation and Impact

Mineral deposits from hard water create significant operational challenges in commercial dishwashers, reducing heating efficiency, blocking spray jets, and shortening equipment lifespan. Scale buildup occurs when dissolved calcium and magnesium precipitate onto heated surfaces, forming hard, chalky deposits that impede water flow and heat transfer. Professional operators report that neglecting descaling protocols can reduce equipment efficiency by 20-30% within six months of operation.

Descaling Procedures and Best Practices

Effective descaling requires systematic procedures tailored to specific machine types and water conditions. Low-temperature machines require careful attention to chemical compatibility, as some sanitizers can react with descaling acids to form hazardous gases. Professional protocols recommend disconnecting chemical feed systems and running multiple rinse cycles before descaling operations.

Manual descaling involves adding descaling solution directly to wash tanks, typically using 4-8 ounces per gallon for light to medium buildup and 8 ounces per gallon for heavy accumulation. The process requires 15-20 minutes of circulation followed by 15 minutes of soaking to allow acid penetration of mineral deposits. Multiple rinse cycles remove residual descaler before returning to normal operation.

Monthly descaling schedules provide optimal results for most commercial operations, though facilities with extremely hard water may require bi-weekly treatment. Professional operators maintain detailed logs tracking descaling frequency and effectiveness to optimize maintenance schedules.

Essential Accessories: Racks, Trays, and Spray Equipment

Dishwasher Racks and Their Applications

Commercial dishwasher racks serve as fundamental accessories that organize items for optimal cleaning while protecting fragile dishware during wash cycles. Professional-grade racks feature open designs that maximize water circulation and air flow, ensuring thorough cleaning and efficient drying. The standard 500mm x 500mm size accommodates most commercial dishwashers, though operators must verify compatibility with specific machine models.

A commercial dishwasher plate rack filled with white plates, demonstrating an essential accessory for kitchen operations

Plate racks utilize vertical tine designs that secure dishes while allowing water access to all surfaces. Professional operators report optimal results when loading plates with soiled surfaces facing spray arms, maximizing cleaning effectiveness. Proper spacing prevents nesting and ensures adequate water circulation around each item.

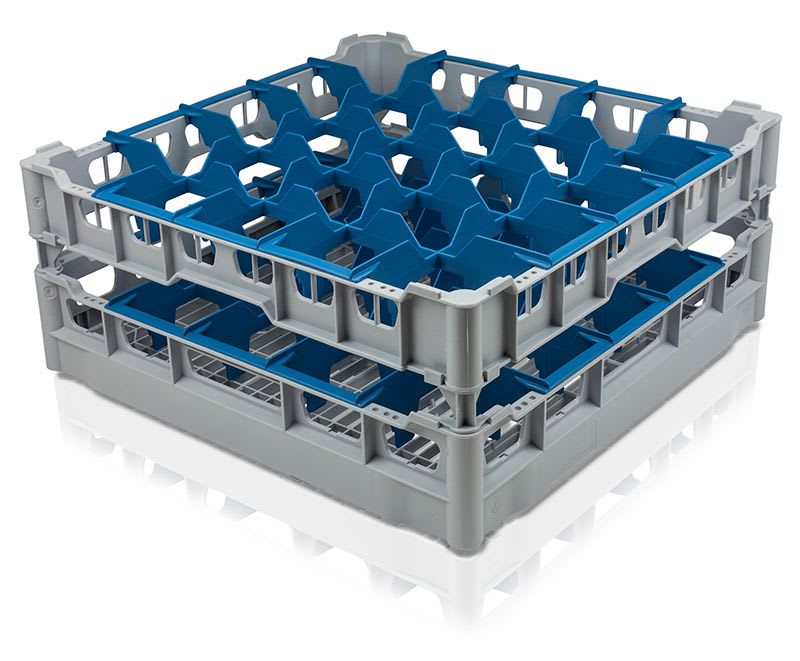

Commercial dishwasher racks with compartmentalized inserts for safely washing glasses

Glass racks incorporate compartmentalized designs that prevent breakage while accommodating various glass types. Specialized inserts enable safe washing of wine glasses, champagne flutes, and other delicate stemware. Professional operators emphasize the importance of proper glass rack selection to minimize replacement costs and maintain service standards.

Blue plastic eight-compartment cutlery holder basket for commercial dishwashers

A light beige plastic commercial dishwasher cutlery basket with multiple compartments and metal handles

Cutlery baskets feature multiple compartments that organize flatware while preventing nesting that impedes cleaning. Professional designs incorporate perforated sides and bottoms to ensure optimal water flow and drainage. Handle-down loading improves safety during unloading while ensuring effective cleaning of eating surfaces.

Pre-Rinse Spray Equipment

Commercial kitchen pre-rinse spray head and hose assembly

A commercial kitchen pre-rinse spray unit, an essential accessory for preparing dishes before dishwashing

Pre-rinse spray equipment represents essential accessories for efficient warewashing operations, enabling removal of food debris before machine washing. Professional-grade spray heads feature ergonomic designs with trigger controls that enable operators to adjust water flow as needed. Flexible hoses provide maneuverability while maintaining consistent water pressure.

Proper pre-rinse temperature settings between 110-120°F optimize soil removal while conserving energy. Professional operators report that effective pre-rinsing reduces main wash cycle time and improves overall cleaning results. Water pressure adjustments accommodate different soil levels and item types.

Transport and Storage Accessories

Professional dishwashing operations benefit from transport trolleys that enable safe movement of loaded racks while minimizing handling time. Drip trays capture residual water during transport, preventing floor contamination and safety hazards. Stacking capabilities maximize storage efficiency during off-peak periods.

Best Practices and Operational Excellence

Temperature Management and Monitoring

Effective temperature control forms the foundation of successful commercial dishwashing operations. High-temperature machines require wash temperatures between 150-180°F and rinse temperatures of 180-195°F for proper sanitization. Low-temperature systems operate at 120-150°F wash temperatures with chemical sanitization providing antimicrobial action.

Professional operators utilize infrared thermometers to verify actual utensil surface temperatures, ensuring compliance with FDA requirements of 160°F for heat sanitization. Regular calibration of temperature monitoring equipment prevents compliance failures and ensures consistent results.

Chemical Safety and Handling Protocols

Professional chemical handling requires comprehensive safety protocols that protect staff while maintaining operational efficiency. Safety Data Sheets for all chemicals must remain readily accessible, with staff training covering proper handling, storage, and emergency procedures. Personal protective equipment including gloves, eye protection, and appropriate clothing prevents chemical contact injuries.

Chemical storage areas require separation from food preparation zones with proper ventilation and spill containment measures. Professional operators implement inventory rotation systems that prevent chemical degradation while ensuring adequate supplies for continuous operation.

Maintenance Scheduling and Documentation

Systematic maintenance scheduling ensures optimal equipment performance while preventing costly breakdowns. Daily tasks include filter cleaning, chemical level monitoring, and temperature verification. Weekly procedures encompass interior cleaning, spray arm inspection, and calibration checks.

Monthly descaling operations prevent mineral buildup that reduces efficiency and shortens equipment life. Quarterly professional service ensures compliance with manufacturer warranties while identifying potential issues before they cause operational disruptions.

Conclusion

Successful commercial dishwasher operations depend on the strategic integration of proper chemicals, essential accessories, and systematic maintenance practices. Professional operators who implement comprehensive chemical management protocols, utilize appropriate accessories, and maintain rigorous maintenance schedules achieve superior cleaning results while maximizing equipment longevity. The investment in quality chemicals and accessories pays dividends through improved efficiency, regulatory compliance, and customer satisfaction in demanding foodservice environments.