Commercial dishwasher installation requires meticulous planning and adherence to strict technical specifications to ensure safe, efficient, and code-compliant operation. The complexity of these installations necessitates comprehensive understanding of electrical, plumbing, and ventilation requirements that vary significantly across different dishwasher types and configurations. Proper preparation during the pre-installation phase is critical for avoiding costly delays, ensuring compliance with local building codes, and achieving optimal performance from the equipment.

The installation process involves coordination between multiple trades including electricians, plumbers, and HVAC technicians, each responsible for specific aspects of the system integration. Modern commercial dishwashers represent sophisticated pieces of equipment that demand precise utility connections, proper ventilation systems, and robust safety measures to operate effectively in high-volume foodservice environments. Understanding these requirements upfront enables facility managers and contractors to budget appropriately and schedule installations efficiently.

Electrical Requirements

Voltage and Amperage Specifications

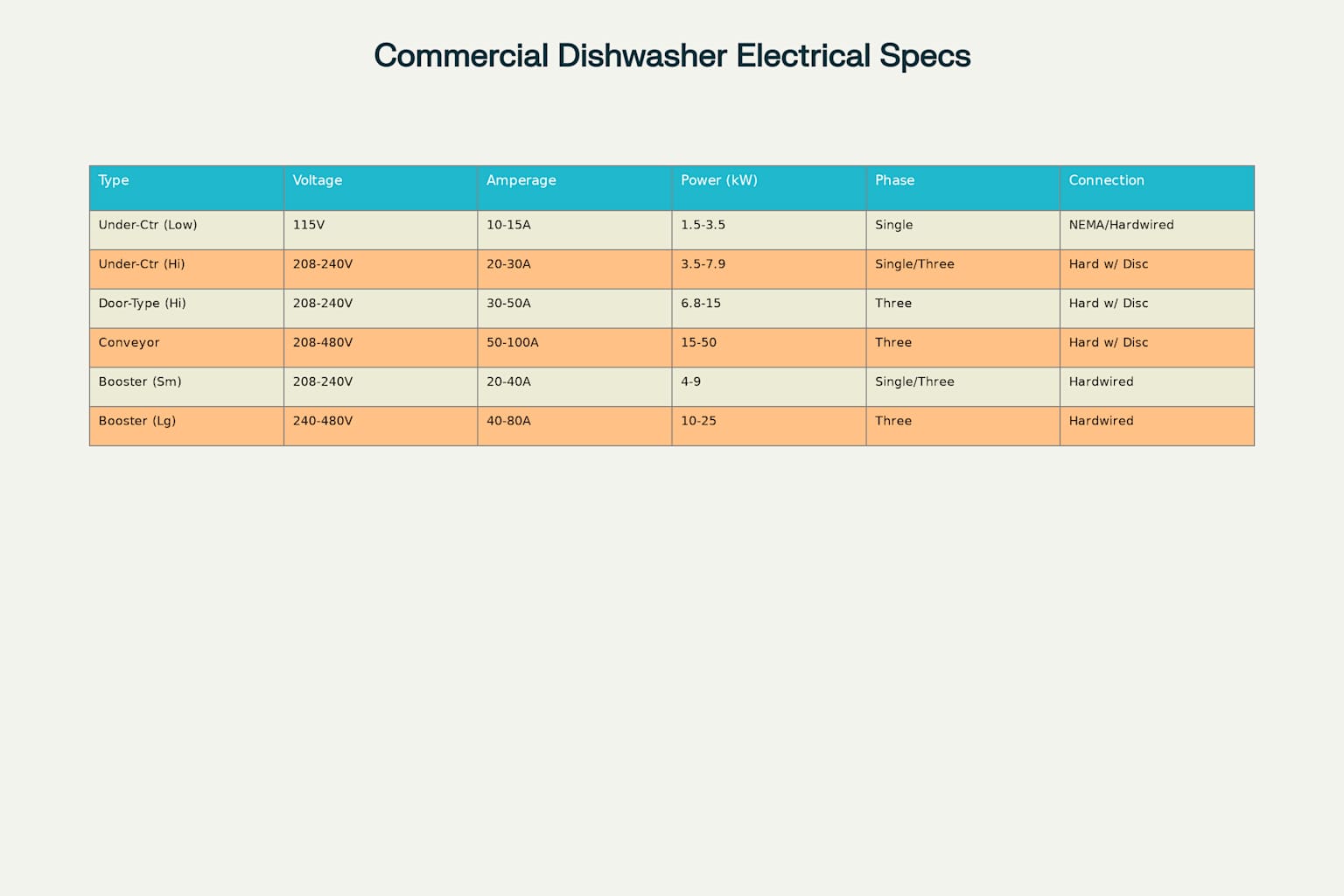

Commercial dishwashers operate across a wide spectrum of electrical requirements depending on their size, type, and sanitization method. Under-counter models typically require 115V single-phase power for low-temperature chemical sanitizing units, drawing between 10-15 amperes. However, high-temperature under-counter dishwashers necessitate 208-240V connections with amperage requirements ranging from 20-30 amperes, often requiring three-phase electrical service.

Door-type dishwashers represent the most common commercial configuration and typically demand 208-240V three-phase electrical service with amperage requirements between 30-50 amperes. These units often incorporate internal booster heaters that significantly increase power consumption, particularly during peak operational periods when both wash and rinse cycles operate simultaneously. The electrical load can reach 6.8-15 kW for standard door-type units, necessitating dedicated electrical circuits with appropriate overcurrent protection.

Electrical requirements for different types of commercial dishwashers and related equipment

Large conveyor dishwashers and flight-type machines represent the most demanding electrical installations, requiring 208-480V three-phase service with amperage draws ranging from 50-100 amperes or higher. These systems often include multiple heating elements, powerful wash pumps, and integrated conveyor motors that contribute to total power consumption exceeding 50 kW in some configurations.

Power Requirements and Load Calculations

Accurate power calculations must account for simultaneous operation of all electrical components including tank heaters, booster heaters, wash pumps, rinse pumps, and control systems. Most commercial dishwashers utilize split electrical loads to prevent excessive current draw on individual circuits. For example, many manufacturers design systems where tank heating elements operate at 1.4-2.1 kW while booster heaters consume 3.0-6.0 kW, with total system consumption remaining below 16 amperes per phase.

The National Electrical Code requires proper sizing of electrical conductors based on the full-load current rating of the equipment plus 25% for motor loads. Energy Star qualified commercial dishwashers must meet specific idle energy rate requirements, with under-counter units limited to 0.30 kW idle consumption for high-temperature models and 0.25 kW for low-temperature chemical sanitizing units.

Disconnect Requirements and Safety Considerations

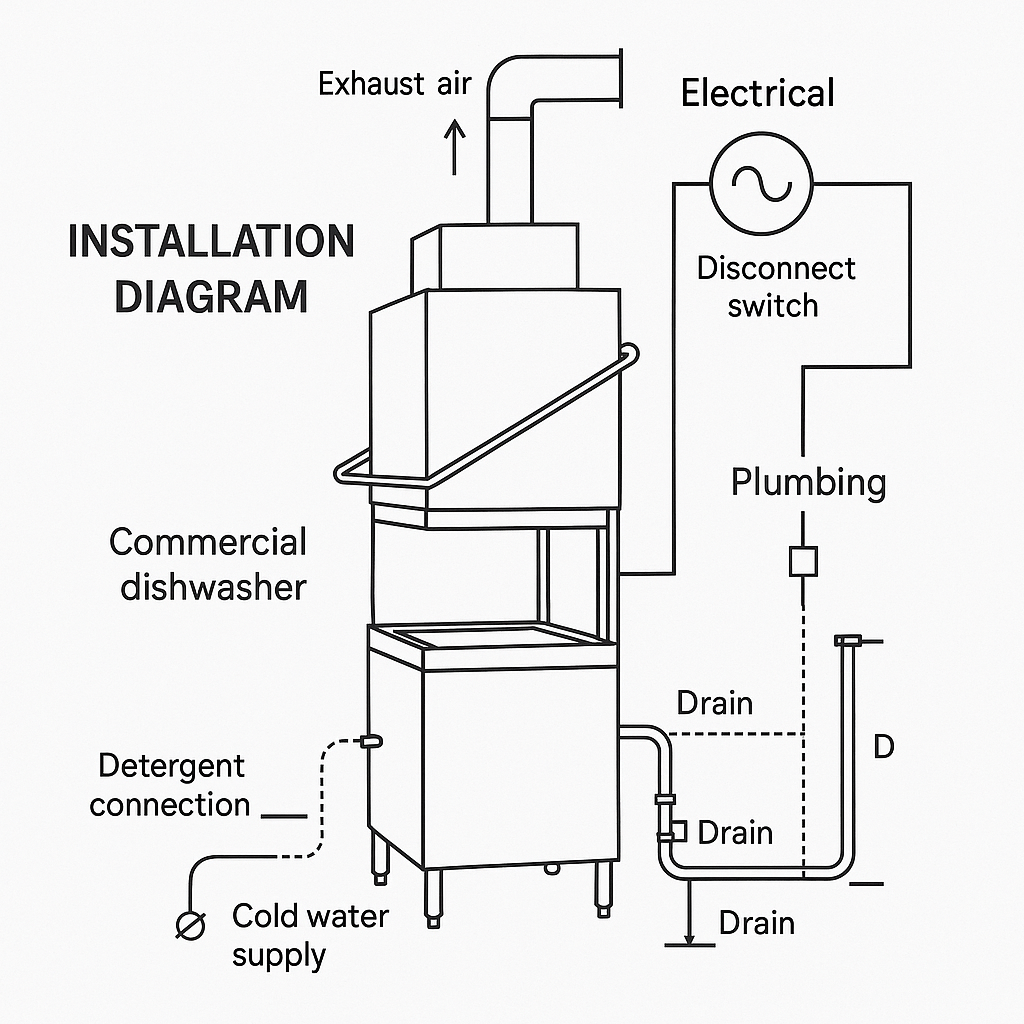

Commercial dishwashers must incorporate appropriate disconnecting means in accordance with NEC Article 422.31(C) for motor-operated appliances rated over 1/8 horsepower. The disconnect must be located within sight of the appliance or provide a separate disconnecting means within sight of the equipment. For commercial installations, this typically requires a fused disconnect switch or circuit breaker rated for the full-load current of the dishwasher.

American-made commercial dishwashers generally require separate disconnect switches, while some European manufacturers include integral unit switches that meet NEC requirements. The disconnect must be readily accessible to operators and service personnel, with NEMA 4 stainless steel enclosures recommended for kitchen environments to resist moisture and cleaning chemicals. Ground fault circuit interrupter (GFCI) protection is required for dishwashers supplied from circuits with voltage to ground of 150 volts or less and protected by overcurrent protection devices of 60 amperes or less.

Plumbing Requirements

Water Supply Specifications

Commercial dishwashers demand consistent water supply with specific pressure, flow rate, and temperature parameters for optimal performance. Water pressure must be maintained between 20-120 PSI, with a minimum of 30 PSI recommended to prevent valve failure and ensure adequate spray pressure. Insufficient water pressure can compromise wash effectiveness and damage internal components, while excessive pressure may cause premature wear of seals and gaskets.

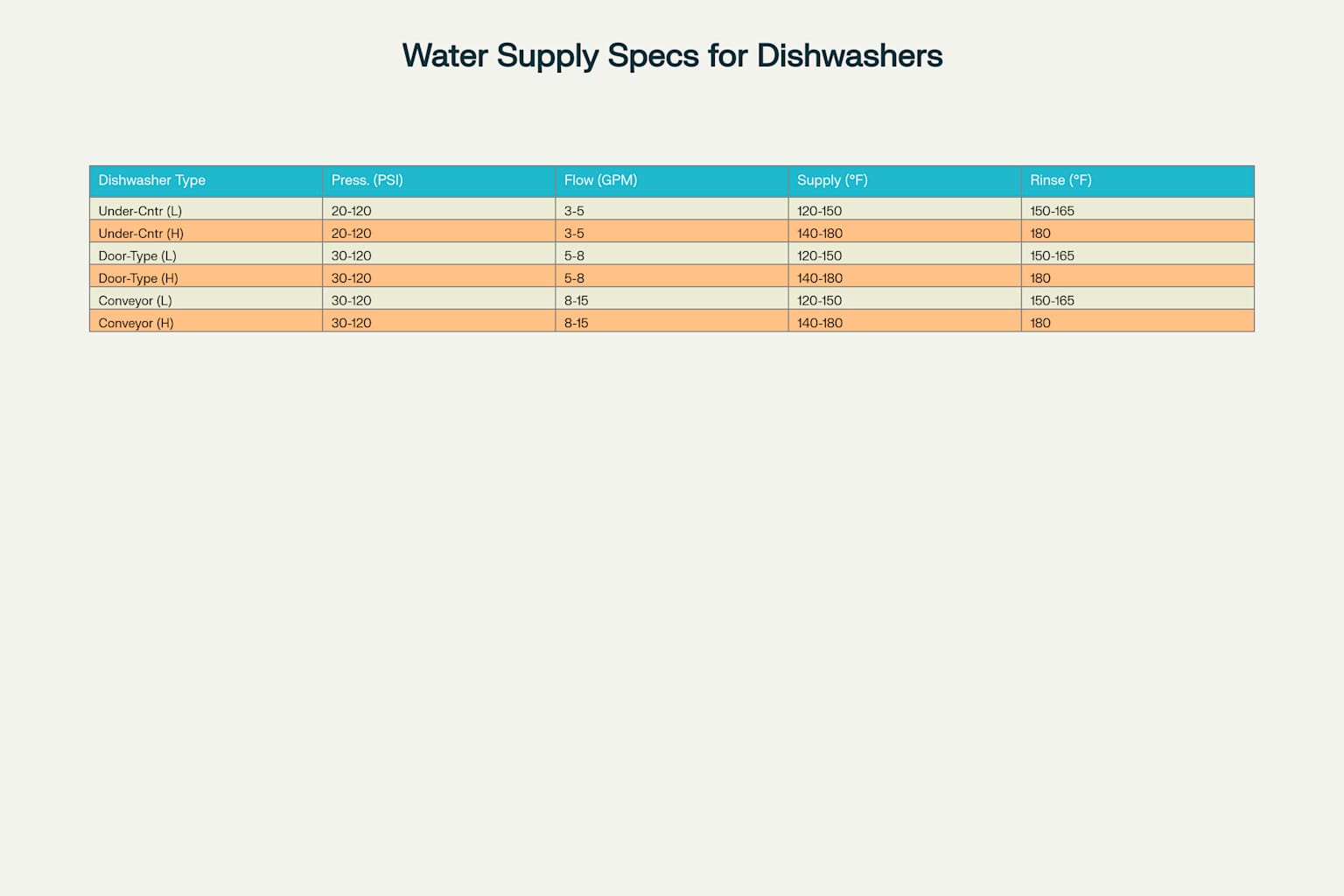

Water supply specifications for different types of commercial dishwashers

Flow rate requirements vary significantly by dishwasher type and capacity. Under-counter units typically require 3-5 GPM, while door-type dishwashers need 5-8 GPM for proper operation. Large conveyor systems may demand 8-15 GPM or higher during peak rinse cycles. These flow rates must be sustained throughout the facility’s peak operating periods, requiring careful coordination with the building’s water supply system and potential installation of pressure tanks or booster pumps.

Water temperature requirements depend on the sanitization method employed. Low-temperature dishwashers using chemical sanitizers require supply water between 120-150°F, though 140-150°F is recommended for optimal cleaning results. High-temperature sanitizing dishwashers need supply water temperatures of 140-180°F to achieve the required 180°F final rinse temperature for proper sanitization. The final rinse temperature must reach 180°F (82°C) to achieve the 5-log reduction of bacteria required by NSF/ANSI Standard 3.

Drainage Requirements and Backflow Prevention

Commercial dishwasher drainage systems must comply with specific plumbing codes to prevent contamination and ensure proper waste removal. The Minnesota Department of Labor and Industry specifies that commercial dishwashing machines must discharge either indirectly to the drainage system through an air break or directly to the drainage system with a floor drain constructed without a backwater valve installed on the horizontal dishwasher branch. The floor drain must be located adjacent to the dishwasher when using direct connection methods.

Indirect drainage connections require an air break to a standpipe, floor sink, or trench drain, providing the most reliable protection against backflow contamination. For gravity drain systems, the waste pipe must be positioned lower than the bottom of the machine to ensure proper drainage. Pump waste systems require upstand connections positioned 3-4 inches below the machine top for optimal drain pump operation.

The water supply connection to commercial dishwashing machines must be protected by an air gap or backflow prevention device in accordance with applicable plumbing codes. Air gaps must maintain a minimum 2-inch separation between the water outlet and flood rim level. Alternative backflow prevention devices must comply with ASSE 1004 standards and include dual check valve assemblies or atmospheric vacuum breakers.

Grease Trap Requirements

Commercial dishwashers handling dishes with food residue require grease trap installation to prevent fats, oils, and grease from entering the sewer system. Grease traps must be sized to handle all kitchen wastewater entering during peak flow periods, with minimum capacity requirements of 20 minutes retention time. A grease trap connected to a single sink should not be smaller than 250 liters (55 gallons) capacity, with larger units required for multiple fixture connections.

The grease trap design must incorporate multiple chambers to allow proper separation of grease and solid waste materials. Wastewater flow through the trap must be sufficiently slow to allow less dense materials to float while heavier solids settle to the bottom. Regular maintenance and pumping are essential to maintain trap effectiveness and prevent system failures that could result in sewer blockages or environmental violations.

Ventilation Requirements

Type II Hood Requirements

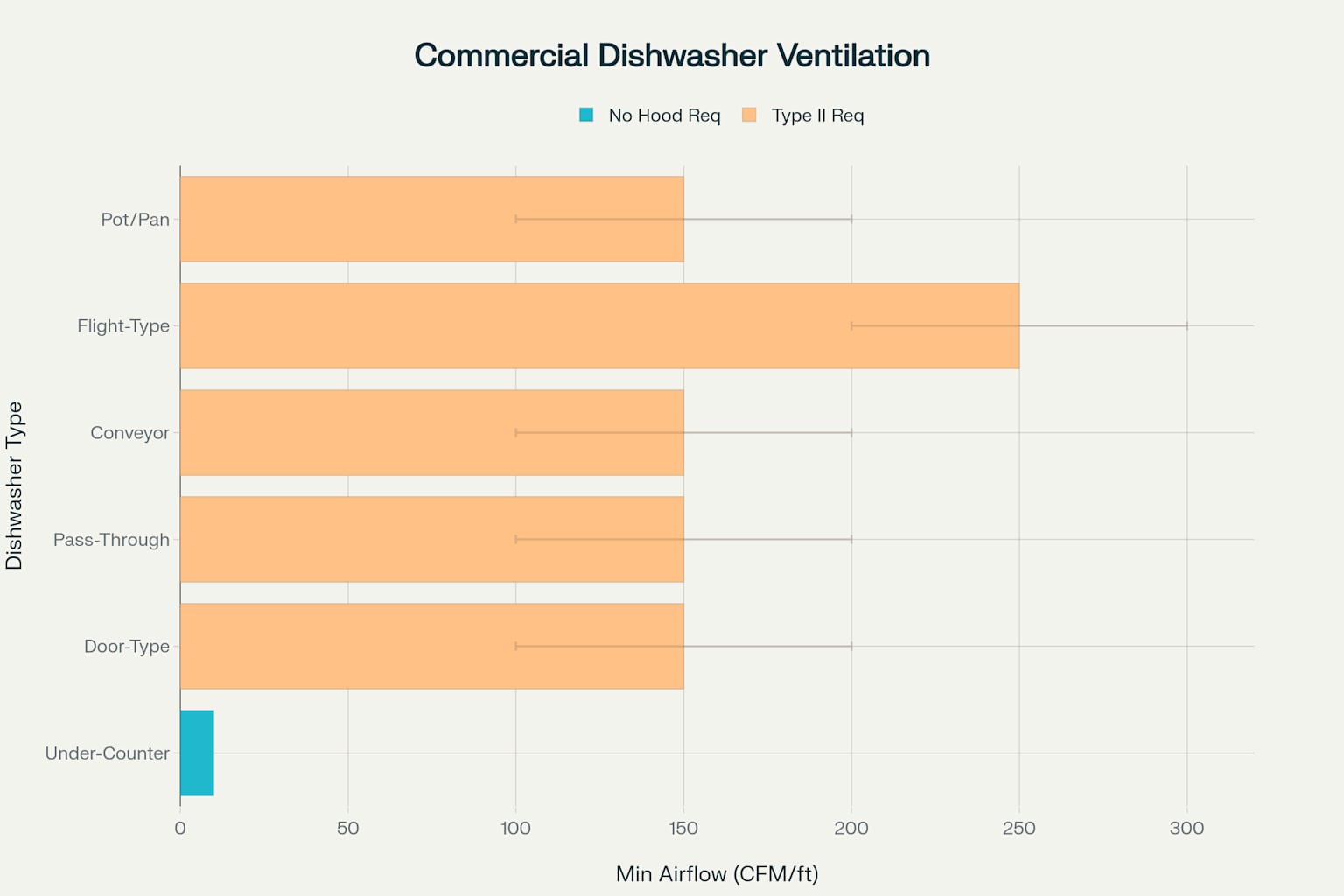

Commercial dishwashers, particularly high-temperature models, generate substantial amounts of steam and heat that require proper exhaust ventilation to maintain acceptable working conditions and prevent moisture damage. Type II condensate hoods are specifically designed for equipment that produces steam and moisture without grease-laden vapors. These hoods must be installed over most commercial dishwashers except under-counter models, which typically do not require hood coverage due to their lower steam production.

Ventilation requirements and hood specifications for commercial dishwashers

The International Mechanical Code (IMC) establishes minimum ventilation requirements of 100 CFM per linear foot of hood length, while the California Mechanical Code requires 200 CFM per linear foot. High-temperature door-type dishwashers typically require 3×3 foot hoods with minimum exhaust rates of 300 CFM, though optimal capture efficiency is achieved with 600-800 CFM. Larger pass-through and conveyor dishwashers may require hoods up to 10 feet in length with proportionally higher exhaust rates.

Hood sizing must account for the specific heat and moisture loads generated by each dishwasher type. Door-type dishwashers under 3×3 foot hoods achieve approximately 38% heat capture at minimum code requirements, while 80% capture efficiency requires increased airflow to 1,000 CFM. Proper hood design includes condensate collection systems to prevent dripping onto equipment below and integrated make-up air systems to maintain kitchen air balance.

Ventless Options and Technologies

Modern ventless dishwasher systems eliminate the need for Type II hood installation through integrated steam capture and condensation technologies. The VRX ventless system captures and cools hot water vapor internally, reducing heat release to the surrounding space and allowing installation in locations where traditional hoods are impractical or cost-prohibitive. These systems are particularly valuable in facilities with limited ceiling height or where ductwork installation is challenging.

Ventless systems incorporate heat recovery technologies that capture steam from wash and rinse cycles, using the recovered energy to preheat incoming water and reduce overall energy consumption. Some advanced systems achieve 22% annual energy cost savings compared to traditional vented models while virtually eliminating steam release into the work area. However, ventless systems typically carry higher initial costs and may require more complex maintenance procedures.

The effectiveness of ventless systems depends on proper installation and regular maintenance of internal condensation and filtration components. These systems work best in facilities with adequate general ventilation and HVAC capacity to handle residual heat loads. Local building codes may still require mechanical permits and specific installation procedures even for ventless models.

Installation and Code Compliance

Commercial dishwasher installation schematic showing electrical, plumbing, and ventilation connections

Ventilation system installation must comply with local mechanical codes and fire safety regulations. The National Fire Protection Association (NFPA) and International Mechanical Code provide guidance for commercial kitchen ventilation design, including requirements for fire suppression system integration. Exhaust ductwork must be properly sized and constructed of appropriate materials to handle the moisture and temperature conditions generated by dishwasher operations.

Make-up air systems are essential components of dishwasher ventilation installations, providing replacement air for that exhausted by the hood system. Inadequate make-up air can create negative pressure conditions that reduce hood effectiveness and increase energy costs. Integrated make-up air systems built into the hood assembly provide the most efficient solution, delivering conditioned air at low velocity to maintain operator comfort.

Proper installation requires coordination with the facility’s overall HVAC system to ensure adequate heating and cooling capacity for make-up air conditioning. Variable speed controls and demand-based ventilation systems can significantly reduce energy consumption while maintaining required exhaust performance. Regular commissioning and testing of ventilation systems ensure continued compliance with health department requirements and optimal energy efficiency.

Conclusion

Successful commercial dishwasher installation requires comprehensive understanding and meticulous attention to electrical, plumbing, and ventilation requirements. The complexity of modern dishwasher systems demands coordination between multiple trades and careful adherence to applicable codes and standards. Proper planning during the pre-installation phase, including accurate load calculations, utility capacity verification, and code compliance review, is essential for achieving optimal equipment performance and avoiding costly modifications or delays.

The investment in proper installation preparation pays dividends through improved equipment reliability, reduced energy costs, and compliance with health department requirements. Facility managers and contractors who thoroughly understand these technical requirements can make informed decisions about equipment selection, infrastructure requirements, and installation scheduling that ultimately contribute to successful foodservice operations.