A Comprehensive Analysis and Future Implementation Strategy

This comprehensive analysis examines the technical evolution of commercial dishwashing systems from their inception in 1886 to present-day AI-powered operations, providing critical insights for advancing next-generation warewashing technology. Through systematic evaluation of architectural developments, performance metrics, and emerging technologies, this report establishes a foundation for strategic R&D investment and implementation planning in the commercial dishwashing sector.

Historical Foundation and Early Development

The commercial dishwasher industry traces its origins to Josephine Cochrane’s groundbreaking invention in 1886, which established the fundamental principles still governing modern warewashing systems. Cochrane’s initial design featured a motor-driven wheel that rotated dishes through jets of hot, soapy water, addressing the critical need for efficient and damage-free cleaning of fine china and commercial dishware. This revolutionary approach demonstrated superior cleaning performance compared to manual washing while significantly reducing breakage rates in commercial establishments.

Josephine Cochrane with her early hand-powered dishwasher, demonstrating a foundational design in dishwasher history

The early 20th century marked a pivotal transformation with the introduction of electric motors in 1917, enabling automated operation and establishing the foundation for modern commercial applications. This period witnessed the development of the first truly scalable commercial systems, characterized by improved water circulation, enhanced heating elements, and the integration of mechanical components that would define subsequent architectural evolution.

Romanian postage stamp commemorating Josephine Cochrane, the inventor of the first practical dishwasher, alongside an illustration of her 1908 design

Mid-Century Technological Breakthroughs

The 1950s introduced the revolutionary Chemical Sanitizing Low-Temperature Dishwasher, developed by John B. Tuthill and WL Dumas, which fundamentally altered the commercial warewashing landscape. This innovation eliminated the need for high-temperature sanitization by incorporating chemical sanitization systems, reducing energy consumption while maintaining NSF compliance standards. The system featured gravity-fed chemical dispensers and cloth curtain enclosures, demonstrating crude but effective implementation of automated chemical dosing technology.

The subsequent decades witnessed rapid technological advancement, with conveyor systems emerging in the 1970s as the dominant architecture for high-volume commercial applications. These systems introduced continuous processing capabilities, enabling throughput rates exceeding 200 racks per hour while maintaining consistent cleaning performance. The integration of microprocessor controls in the 1990s marked another significant milestone, providing precise cycle management and energy optimization capabilities.

Architectural Evolution and Performance Analysis

Fundamental Architecture Classifications

Contemporary commercial dishwashing systems are classified into four primary architectural categories, each optimized for specific operational requirements and capacity demands. The undercounter configuration represents the most compact solution, typically processing 24-60 racks per hour with water consumption rates of 0.8 gallons per rack. These systems excel in space-constrained environments such as small cafés and bars, offering rapid cycle times of 90 seconds while maintaining high-temperature disinfection capabilities.

A modern commercial kitchen dishwashing area featuring both a compact hood type dishwasher.

Hood-type or pass-through dishwashers constitute the intermediate category, designed for medium-capacity operations with throughput rates of 60-120 racks per hour. These systems feature lifting or sliding hood mechanisms that provide ergonomic loading access while maintaining operational efficiency. The architecture incorporates dual-zone washing with separate pre-wash and final rinse chambers, enabling superior soil removal performance.

High-Volume Conveyor and Flight-Type Systems

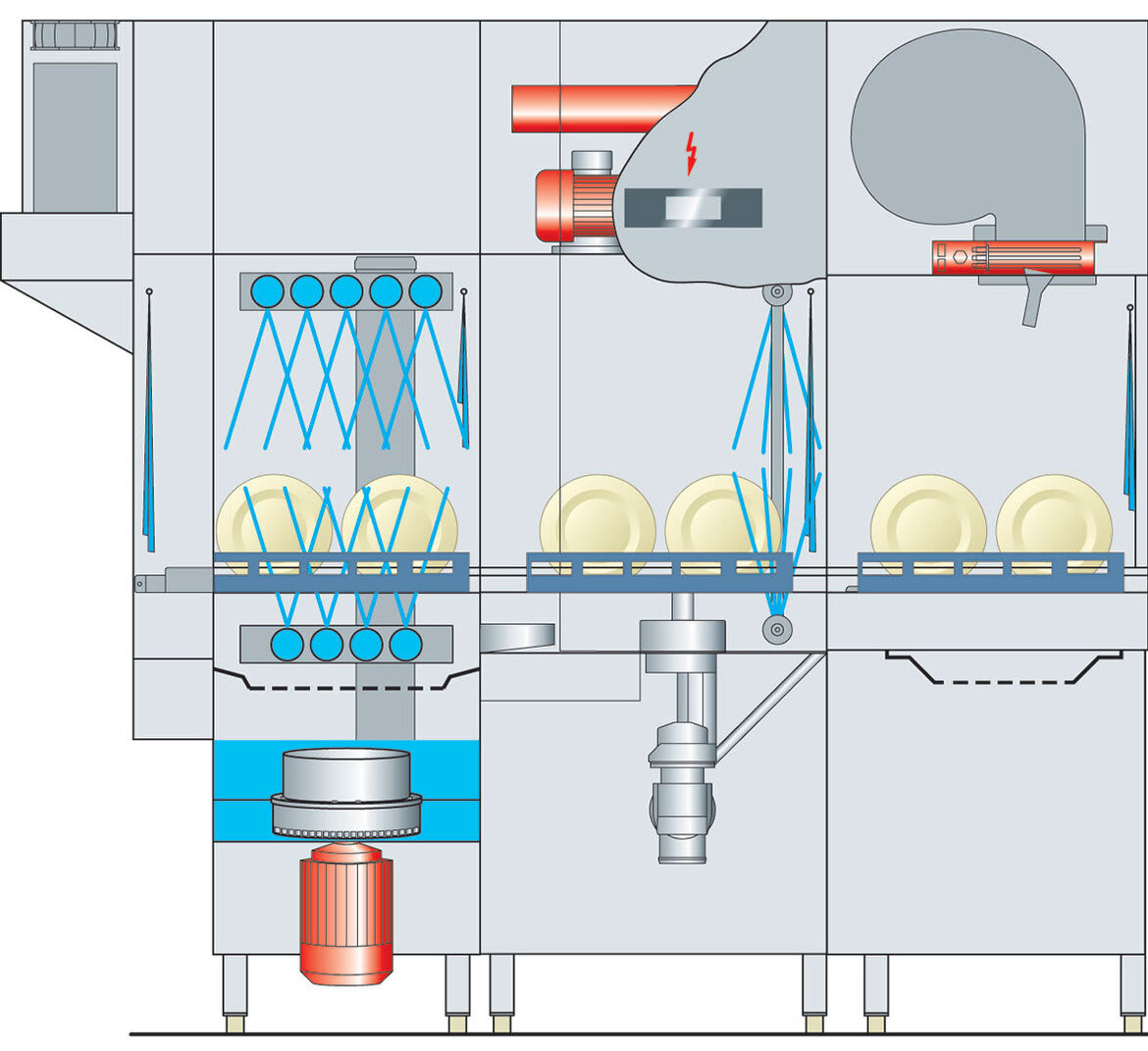

Conveyor dishwashers represent the most sophisticated architectural evolution, designed for large-scale commercial operations with capacity requirements exceeding 200 racks per hour. These systems incorporate continuous belt mechanisms that transport dish racks through sequential washing, rinsing, and drying zones, achieving optimal resource utilization and consistent cleaning results. Advanced models feature automatic soil removal (ASR) systems that continuously filter wash water, reducing pre-scraping requirements and extending tank life.

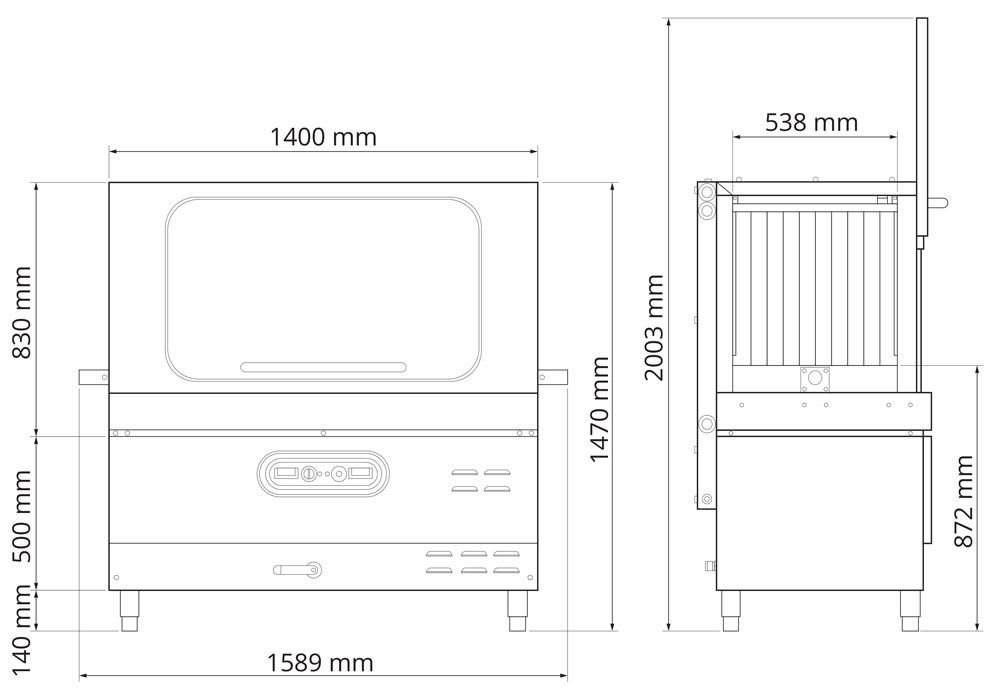

Technical diagram of a Mach MST140 commercial conveyor tunnel dishwasher with detailed dimensions in millimeters.

Technical diagram of a commercial rack conveyor dishwasher, showing the multi-stage washing, rinsing, and drying process. Walex has similiar dishwasher like this.

Flight-type dishwashers represent the pinnacle of commercial warewashing technology, capable of processing 300-500 racks per hour in high-volume institutional applications. These systems feature extended conveyor sections with multiple wash and rinse zones, incorporating advanced heat recovery and water recycling technologies. The architecture enables continuous operation with minimal operator intervention, making them ideal for mass feeding operations, hospitals, and large institutional kitchens.

A modern stainless steel flight-type commercial dishwasher for high-volume industrial kitchen

Comparative Performance Analysis

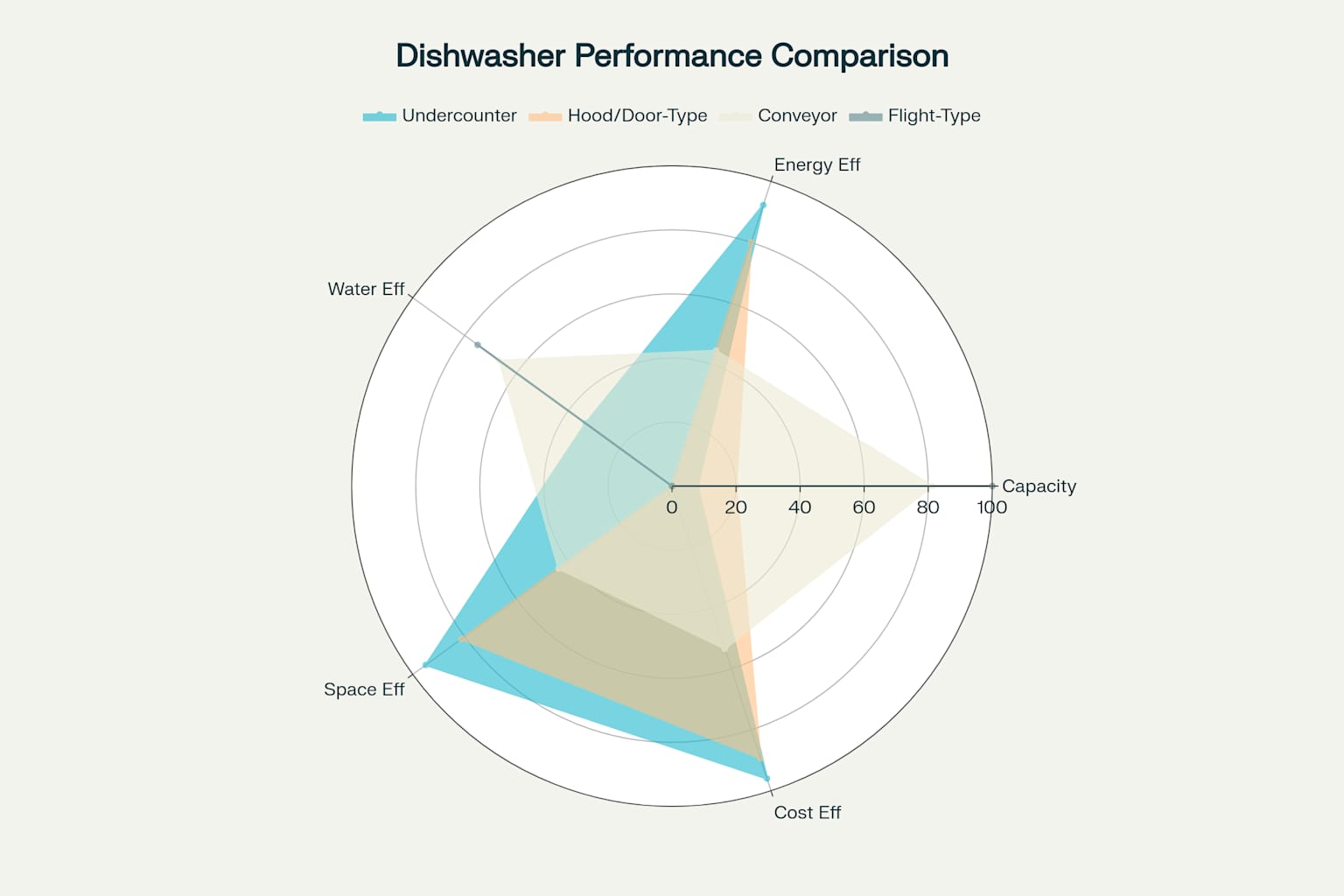

Modern commercial dishwasher architectures demonstrate significant performance variations across key operational metrics, reflecting their specialized design objectives and target applications.

Flight-type systems achieve the highest throughput rates at 300 racks per hour while maintaining the lowest per-rack water consumption at 0.3 gallons, demonstrating superior efficiency in high-volume applications. However, these systems require substantial energy inputs of 45 kW and installation footprints of 80 square feet, representing significant capital and operational investments.

Commercial Dishwasher Architecture Performance Comparison

The performance analysis reveals critical trade-offs between capacity, efficiency, and operational requirements, with each architecture optimizing specific performance parameters at the expense of others. Undercounter systems excel in space efficiency and initial cost, while conveyor and flight-type systems demonstrate superior water and energy efficiency per unit processed. These architectural variations reflect the industry’s response to diverse operational requirements and economic constraints across commercial applications.

Contemporary Technology Integration and Performance Metrics

Efficiency Evolution and Resource Optimization

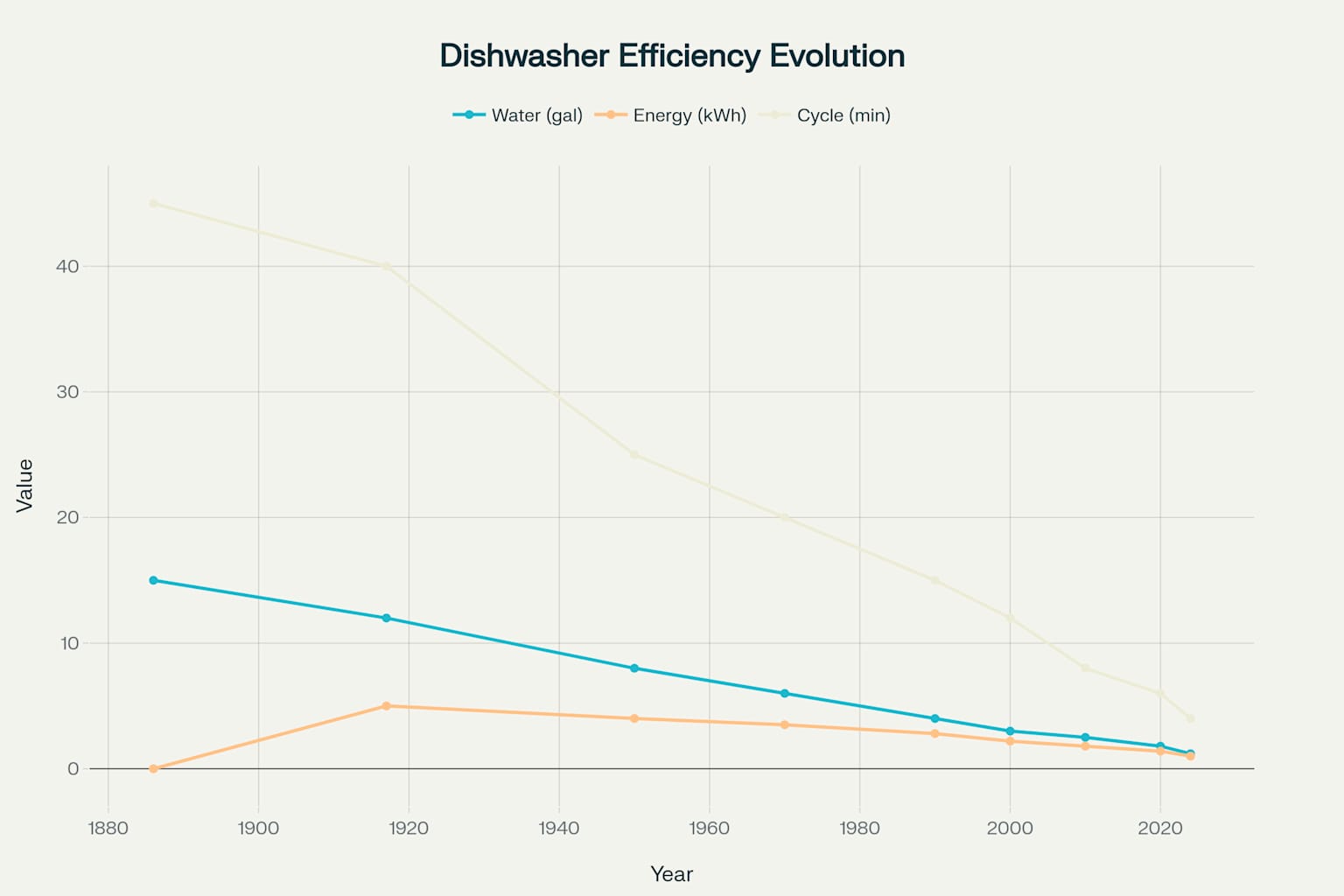

The dramatic improvement in commercial dishwasher efficiency over the past 138 years demonstrates the industry’s commitment to resource optimization and operational excellence.

Water consumption has decreased from 15 gallons per cycle in 1886 to 1.2 gallons in 2024, representing a 92% reduction in resource utilization. Simultaneously, cycle times have been reduced from 45 minutes to 4 minutes, achieving an 89% improvement in operational efficiency.

Evolution of Commercial Dishwasher Efficiency (1886-2024)

This efficiency evolution reflects the integration of advanced technologies including smart sensors, energy recovery systems, and AI-powered operational controls. Modern systems incorporate soil sensors that automatically adjust water pressure and chemical concentration based on load requirements, optimizing resource utilization while maintaining cleaning performance. Heat recovery systems, now adopted in 85% of commercial installations, recycle thermal energy from drain water to preheat incoming water, reducing energy consumption by up to 70%.

Smart Technology Integration and IoT Connectivity

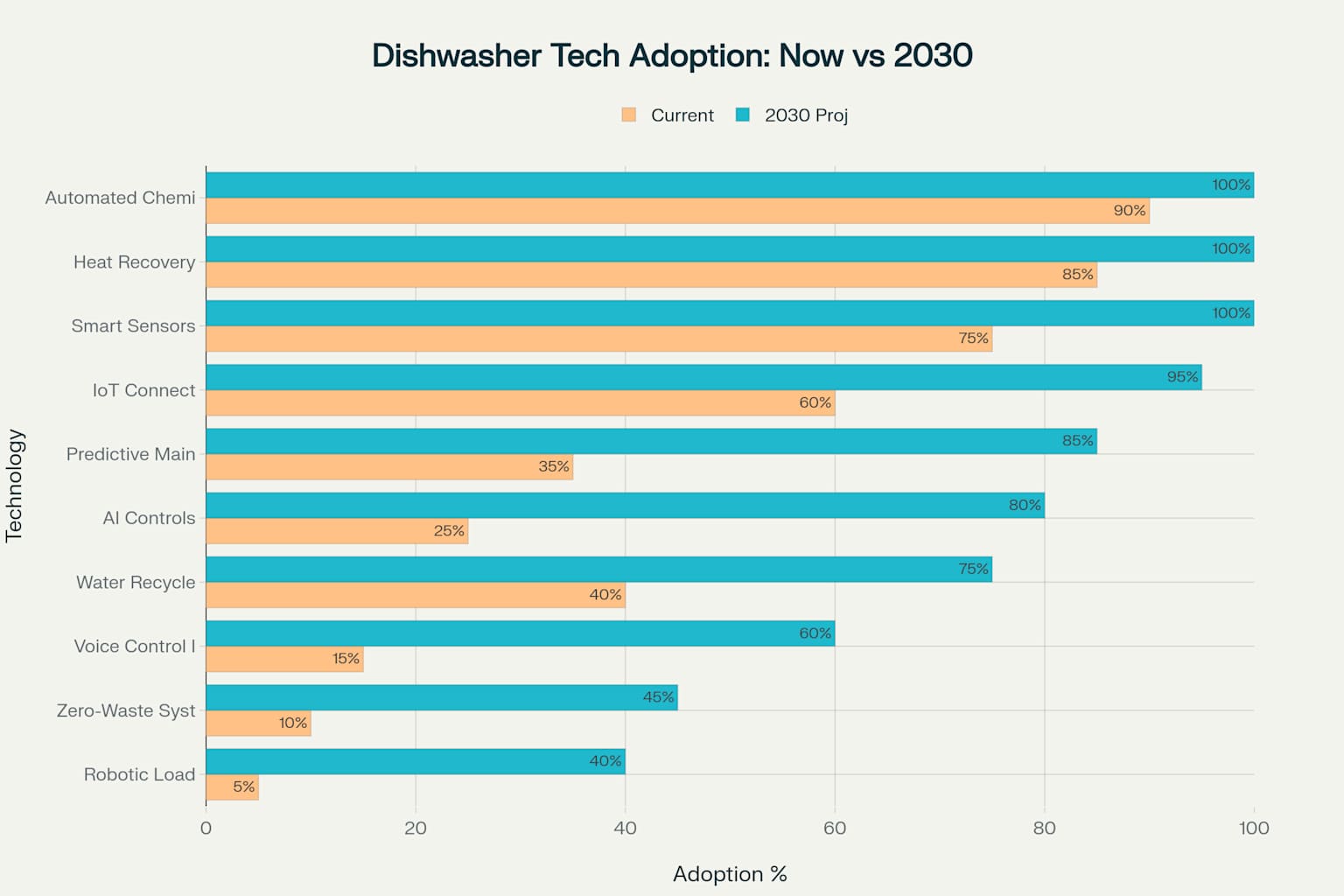

The integration of Internet of Things (IoT) technology represents a fundamental shift in commercial dishwasher operation and management, with current adoption rates reaching 60% across the industry. IoT-enabled systems provide real-time monitoring of operational parameters including water temperature, chemical levels, cycle performance, and energy consumption. Advanced implementations incorporate predictive maintenance algorithms that analyze equipment performance data to anticipate potential failures and optimize maintenance scheduling.

Smart dishwashers utilize machine learning algorithms to optimize washing cycles based on load characteristics, soil levels, and operational history. These systems can automatically adjust water pressure, temperature, and chemical dosing to achieve optimal cleaning results while minimizing resource consumption. Voice control integration, currently adopted in 15% of installations, enables hands-free operation and status monitoring, improving operational efficiency and user experience.

Cutting-Edge Technologies and Future Directions

Artificial Intelligence and Machine Learning Integration

The integration of artificial intelligence represents the most significant technological advancement in contemporary commercial dishwasher development, with current adoption rates of 25% projected to reach 80% by 2030. AI-powered systems utilize computer vision technology to identify dish types, assess soil levels, and optimize cleaning parameters in real-time. The SMART VISION CONTROL system developed by Hobart incorporates neuronal networks trained on over 80,000 images to classify dishware and automatically adjust washing parameters.

Commercial Dishwasher Technology Adoption: Current vs Projected 2030

Advanced AI implementations include automated soil removal systems that continuously assess wash water quality and adjust filtration cycles accordingly, maintaining optimal cleaning conditions throughout extended operation periods. These systems demonstrate up to 30% reduction in water consumption and 20% improvement in cleaning performance compared to conventional control systems.

Robotic Automation and Autonomous Operation

Robotic dishwashing systems represent the next frontier in commercial warewashing automation, addressing critical labor shortages while improving operational consistency. Current implementations utilize collaborative robots equipped with computer vision and machine learning algorithms to perform dish handling, scraping, and loading operations. The Spotless system by Nala Robotics demonstrates commercial viability with rental options at $2,995 per month, indicating strong market demand for automated solutions.

Advanced robotic systems incorporate 3D pose estimation and object recognition capabilities to handle diverse dishware types while preventing damage. Suction-powered gripping systems enable gentle handling of fragile items while maintaining high throughput rates. These systems demonstrate 40-60% improvement in processing speed while reducing labor requirements and improving consistency.

Sustainability and Environmental Innovation

Water recycling and closed-loop systems represent critical technological advancement addressing environmental regulations and operational cost reduction. Advanced filtration systems incorporating ultrafiltration, UV sterilization, and ozone treatment enable 90% water recovery rates while maintaining sanitary standards. The KitchenAid AquaSense system demonstrates practical implementation of water recycling technology, reducing consumption by up to 33% compared to conventional systems.

Zero-waste dishwashing systems, currently adopted in 10% of installations with projected growth to 45% by 2030, eliminate chemical waste and water discharge through closed-loop chemical recycling and advanced water purification. These systems incorporate multiple treatment stages including biological processing, chemical neutralization, and advanced filtration to achieve complete waste elimination.

Strategic Implementation Plan and Technology Roadmap

Phased Development Strategy

The strategic implementation of next-generation commercial dishwasher technology requires a systematic four-phase approach spanning 2025-2030, with total investment requirements of $11.5 million. Phase 1 focuses on foundation technologies including AI-powered vision control systems and IoT integration platforms, requiring $4.5 million investment over 24 months. These systems incorporate high-resolution cameras, depth sensors, and machine learning algorithms to achieve 20% reduction in water and chemical consumption.

Phase 2 introduces robotic automation systems including collaborative robots with suction grippers and 3D pose estimation capabilities, targeting 40-60% improvement in processing speed. The integration of Automated Soil Removal 2.0 systems provides AI-driven assessment of soil levels with dynamic cycle adjustment, achieving up to 30% reduction in water consumption.

Advanced Technology Integration

Phase 3 emphasizes sustainability integration through closed-loop water recycling systems and advanced heat recovery technologies. The implementation of ultrafiltration, UV sterilization, and ozone treatment systems enables 90% water recovery rates while maintaining NSF compliance standards. Heat recovery systems utilizing drain water energy recovery (DWER) with heat pumps achieve up to 70% energy recovery from waste heat with 18-24 month payback periods.

Phase 4 introduces zero-waste operation capabilities and predictive maintenance systems, targeting complete elimination of chemical waste and water discharge. Advanced sensor integration including vibration, temperature, pressure, and flow rate monitoring enables machine learning-based failure prediction, reducing unplanned downtime by 50%.

Performance Targets and Investment Analysis

The implementation strategy targets ambitious performance improvements including water consumption reduction to less than 0.2 gallons per rack and energy consumption below 0.8 kWh per cycle. Cycle time optimization targets 2-3 minute average processing with system uptime exceeding 99.5% availability. These performance targets represent significant advancement over current industry standards while maintaining economic viability and regulatory compliance.

The financial analysis projects 25% market share capture in the premium commercial dishwasher segment with 35% year-over-year revenue growth and 28% gross profit margins. The implementation strategy anticipates 150% return on investment by 2030, demonstrating strong economic justification for technology development and market deployment.

Conclusion

The evolution of commercial dishwasher technology from Josephine Cochrane’s 1886 mechanical system to contemporary AI-powered operations represents one of the most significant technological transformations in commercial kitchen equipment. The systematic analysis of architectural development reveals consistent optimization of efficiency, capacity, and operational convenience while addressing evolving regulatory requirements and environmental concerns.

The integration of cutting-edge technologies including artificial intelligence, robotic automation, and closed-loop sustainability systems positions the commercial dishwashing industry for continued innovation and growth. The strategic implementation plan provides a comprehensive roadmap for technology development and market deployment, addressing critical performance objectives while ensuring economic viability and competitive advantage.

Future research and development efforts must continue addressing labor shortage challenges, environmental sustainability requirements, and operational efficiency optimization while maintaining the fundamental commitment to cleaning performance and food safety that has defined the industry since its inception. The successful implementation of next-generation dishwashing technology will require continued collaboration between equipment manufacturers, technology developers, and end-users to ensure practical solutions that address real-world operational requirements and economic constraints.